iCNC Performance

Manual 0-5401 iCNC SETUP 7-5

7.3.3 Encoder Values Step/Dir

Put the Drive Enable on the front of the controller to “ON”

It is advisable to use low speeds for testing, decrease speed from speed potentiometer,

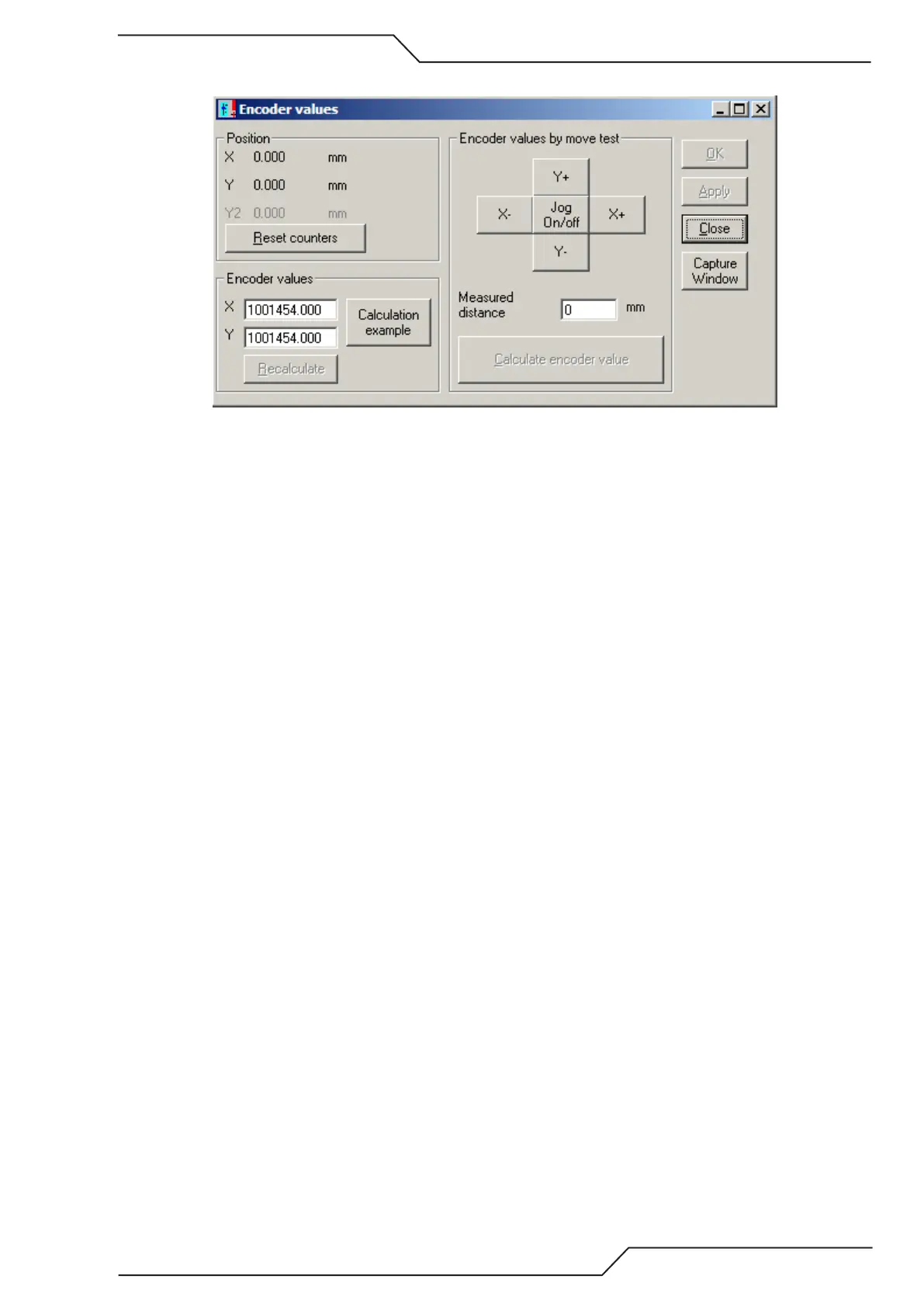

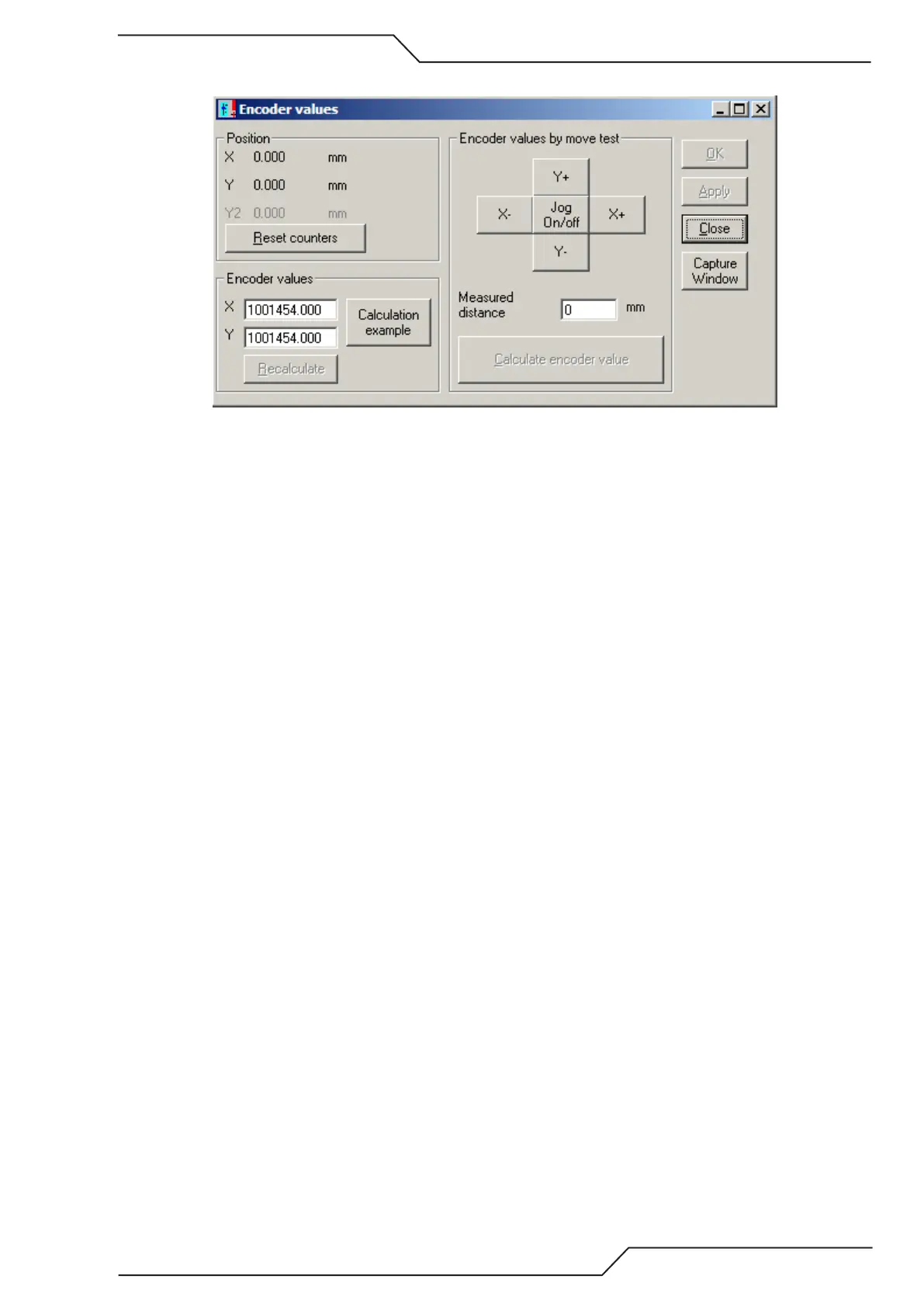

Move the machine to the front of the rail or reference mark. Reset the encoder counters by pressing the Reset counters

button or the yellow 0,0 button in the panel. Press the “Jog ON/OFF” button to enter manual mode (note: the manual

mode button will flash ON-OFF). Using a drive direction button, move the machine as long of a distance as is possible.

Measure the machine position from the end of the rail or reference mark, using a metric tape measure. Key this distance,

the machine actually moved, into the “Measured distance” box as a metric value and click the “Calculate encoder value”

button. Repeat the previous procedure with the other axis for machines with different rack and pinion combination, or

simply copy and paste the calculated encoder value in the opposite encoder value box and press “Recalculate”. Click

Reset counters then click Apply and OK when done.

The encoder value corresponds with pulse edges per one meter of motion. The bigger you set the encoder value the

bigger it will make the programmed figures.

Example: If you drive a distance of one meter according to your encoder reading, and the actual measured motion dis-

tance of the machine is 997 mm, you must divide your current encoder value by 0.997 in order to make the machine cut

parts to the correct size.

Normal encoder values are in the 100 000 – 5 000 000 range.

Metric: (1000mm x encoder pulses per revolution x 4 x gear ratio) / (module x π x number of teeth in pinion) = Encoder

value

Imperial: (39.37 x encoder pulses per revolution x 4 x gear ratio) / (Effective diameter x π) = Encoder value

If using example Teknic motors without a real encoder feedback, pulses per revolution is multiplied by 2 not 4.

If your measured distance and the distance the CNC measured are different. To recalculate a new encoder value by di-

viding the current encoder value being used by the actual measured distance and then multiply that by the commanded

distance (distance displayed on the Encoder value screen under Position).

• Encoder value in screen =1143818.000

• Actual moved distance = 3000mm

• CNC displayed distance = 1500mm 1143818.000 / 3000= 381.273

• 318.237 x 1500= 571909.5

• Correct encoder value = 571909.5

If needed, redo steps listed above until the correct encoder value has been achieved. (The moved distance should match

the CNC displayed distance).

Click Reset Counters, then Apply and OK.

Put the Drive Enable Switch on the front of the controller to “OFF”

Loading...

Loading...