iCNC Performance

Manual 0-5401 MAINTENANCE AND TROUBLESHOOTING 8-5

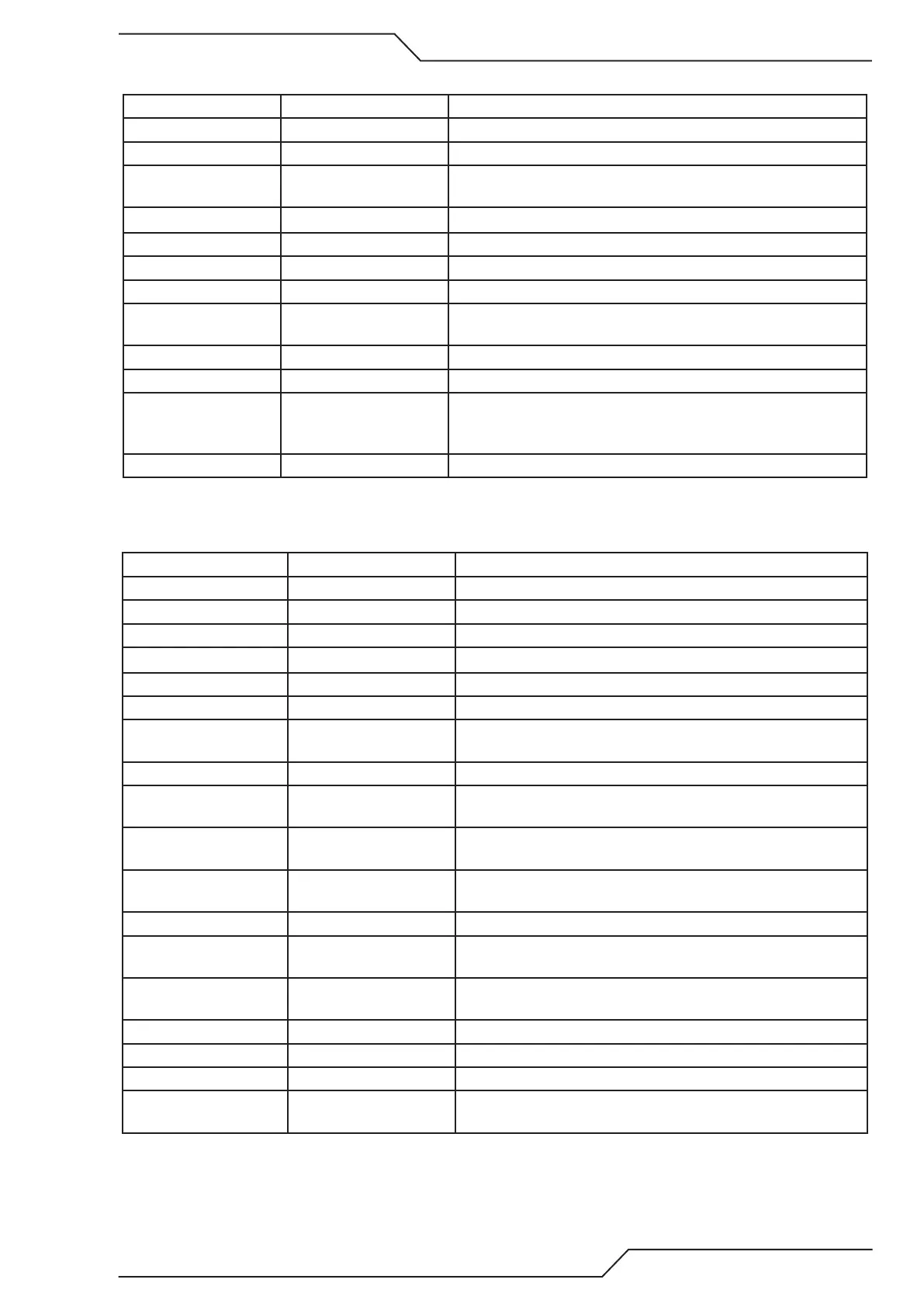

8.2.4 Motion Issues

Problem Cause What to check

Motors won’t move Enable OFF Turn enable switch to ON

SW Enable OFF See error messages.

Speed set to 0 Turn the speed potentiometer to 100%, press the speed up button

to increase the speed.

External stop active Check continuity between E1 and E2 in the power connector.

Motors move slowly Limit switch tripped Check limit switches

Collision tripped Check collision sensor

Speed set to low Turn the speed potentiometer to 100%, and/or press the speed up

button to increase the speed.

Encoder value wrong Check encoder value is correct

Position Error mes-

sage after enable is

turned ON

Wrong motor or encoder

polarity

Check motor/encoder polarity is correct

Drift too high Adjust drift close to zero

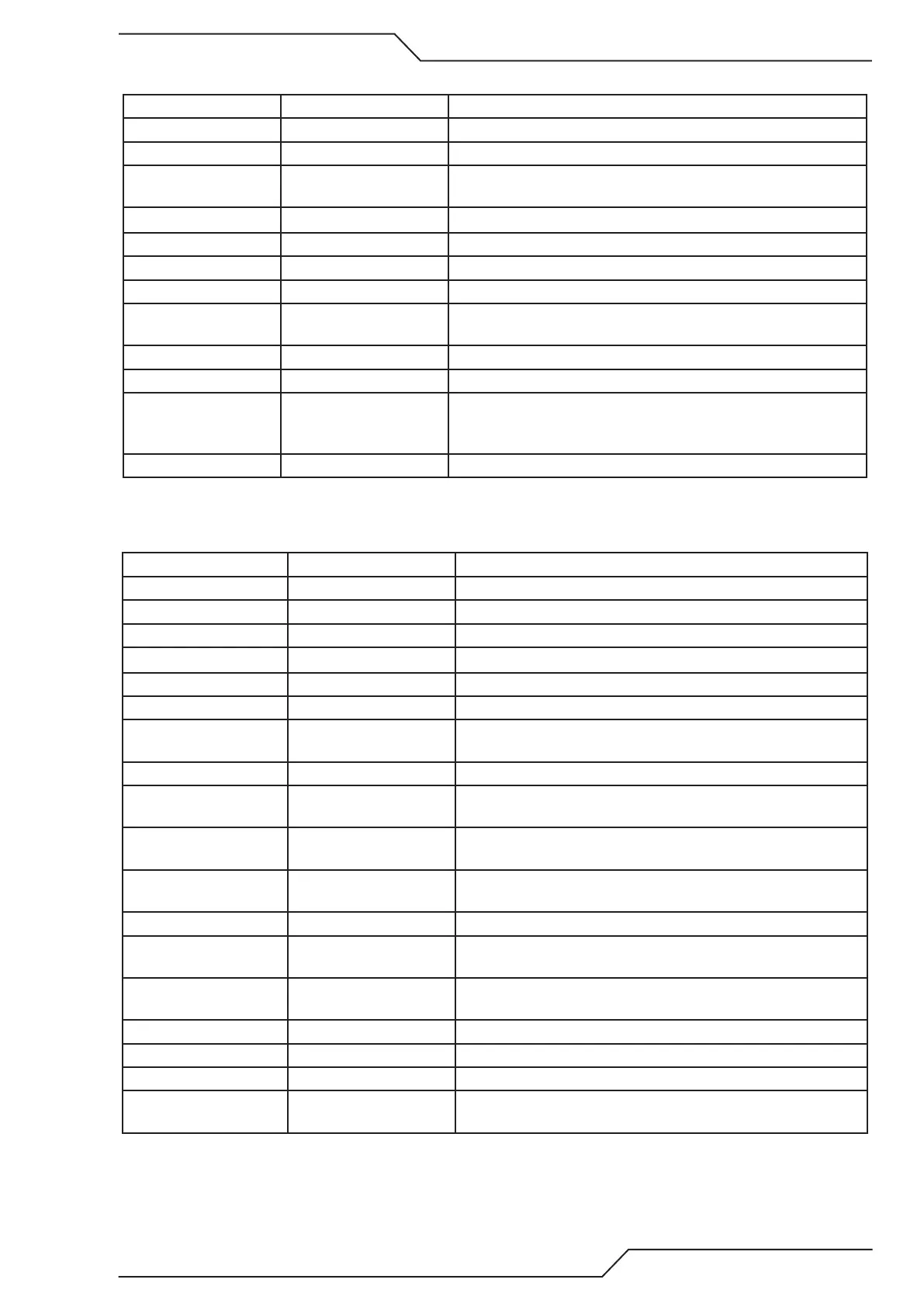

8.2.5 IO Issues/ Error Messages

Problem Cause What to check

Outbits will not activate External Stop pressed in Release External stop

Limit switches Machine parked to limit Move machine away from the limit switch

No inbit 04 Main arc Torch too far from plate Check ignition height settings

Error in plasma Check and clear plasma errors

No main arc signal from

plasma

Broken cable, check continuity from plasma to CNC/Height

control

Continuous torch col-

lision

Dirt in proximity switch-

es

Clean proximity switches

Broken or unplugged

cable

Check proximity switch cables

Proximity switch out of

adjustment

Check correct proximity switch adjustment

Continuous plate

contact

Wrong consumables Check consumables

Consumbales incorrectly

assembled

Cehck consumbales are in correct order and seated properly

Torch sitting on the plate Check torch position

Ohmic cable broken Ohmic cable shorted to work, check cable

System halted outputs

disabled

External stop pressed in Release external stop. Check continuity between E1 and E2 in the

power connector.

Loading...

Loading...