iCNC Performance

Manual 0-5401 iCNC SETUP 7-11

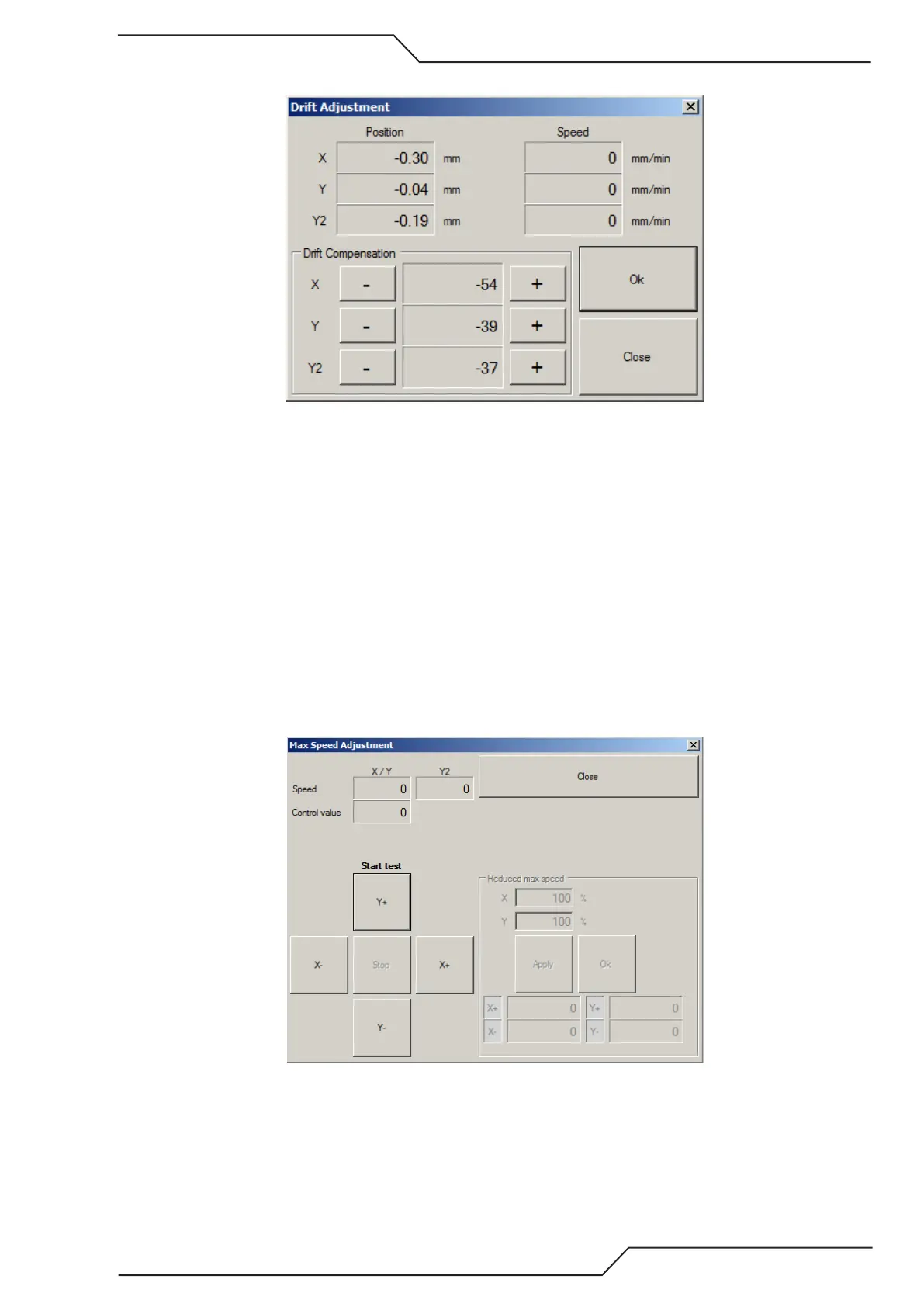

7.4.4 Drift Adjustment Analog Speed

Drift Adjustment from iCNC Setup will open the positioning loop and allow the machine to drift if the electrical settings

are not perfect.

Put the Drive Enable on the front of the controller to “ON” and adjust the motion to zero drift using the + and - buttons.

Each click will change 0 level by 0.6mV. Use + and - buttons to get the zero level speed as close to 0 as possible for each

axis. You can keep the button pressed in to scroll the values. Maximum range for values is +383 - -383.

If you cannot get the machine stable, set the values to 0 and adjust from the servo amplifier.

Default 0 level has been set at the factory.

Clicking OK will save the values.

View machine motion through the position counters in the Drift adjustment window in iCNC Setup.

Press the yellow ZERO push button on the controller before clicking Close. Clicking Close in the Drift adjustment window

will close the positioning loop and allow you to resume positional control.

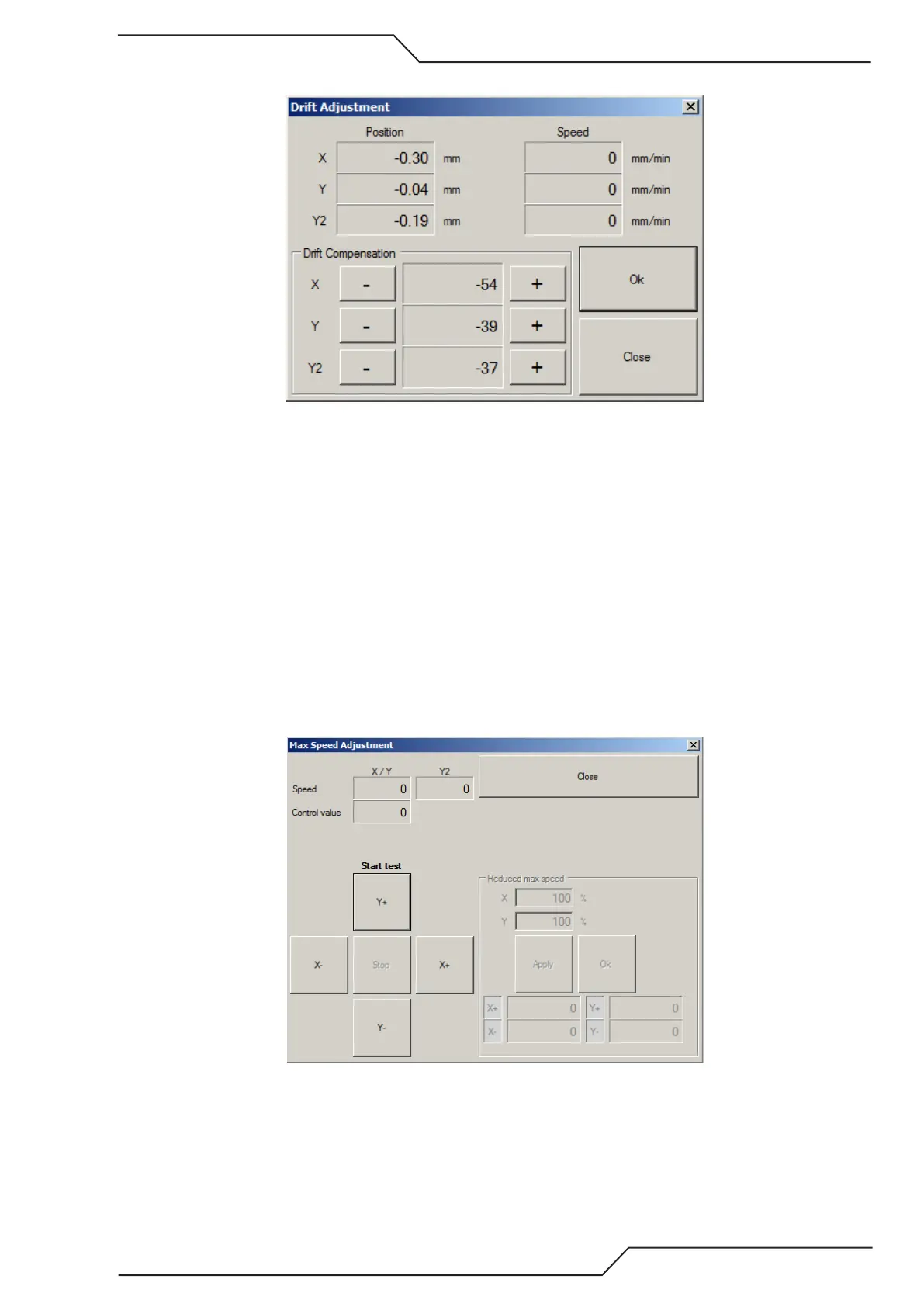

7.4.5 Max Speed Adjustment Analog Speed

This will let you drive with the maximum speed, making it possible to see the true speeds for each axis. Adjust the speed

scaling from your servo amplifiers if needed. Max speed percentage adjustment and speed check is disabled when using

analog speed signal.

Make sure your speed potentiometer is set to 100% and put the Drive Enable on the front of the controller to “ON”.

Pressing any of the directional keys will ramp up the speed to max and drive with full speed until Stop is pressed.

Loading...

Loading...