iCNC Performance

8-4 MAINTENANCE AND TROUBLESHOOTING Manual 0-5401

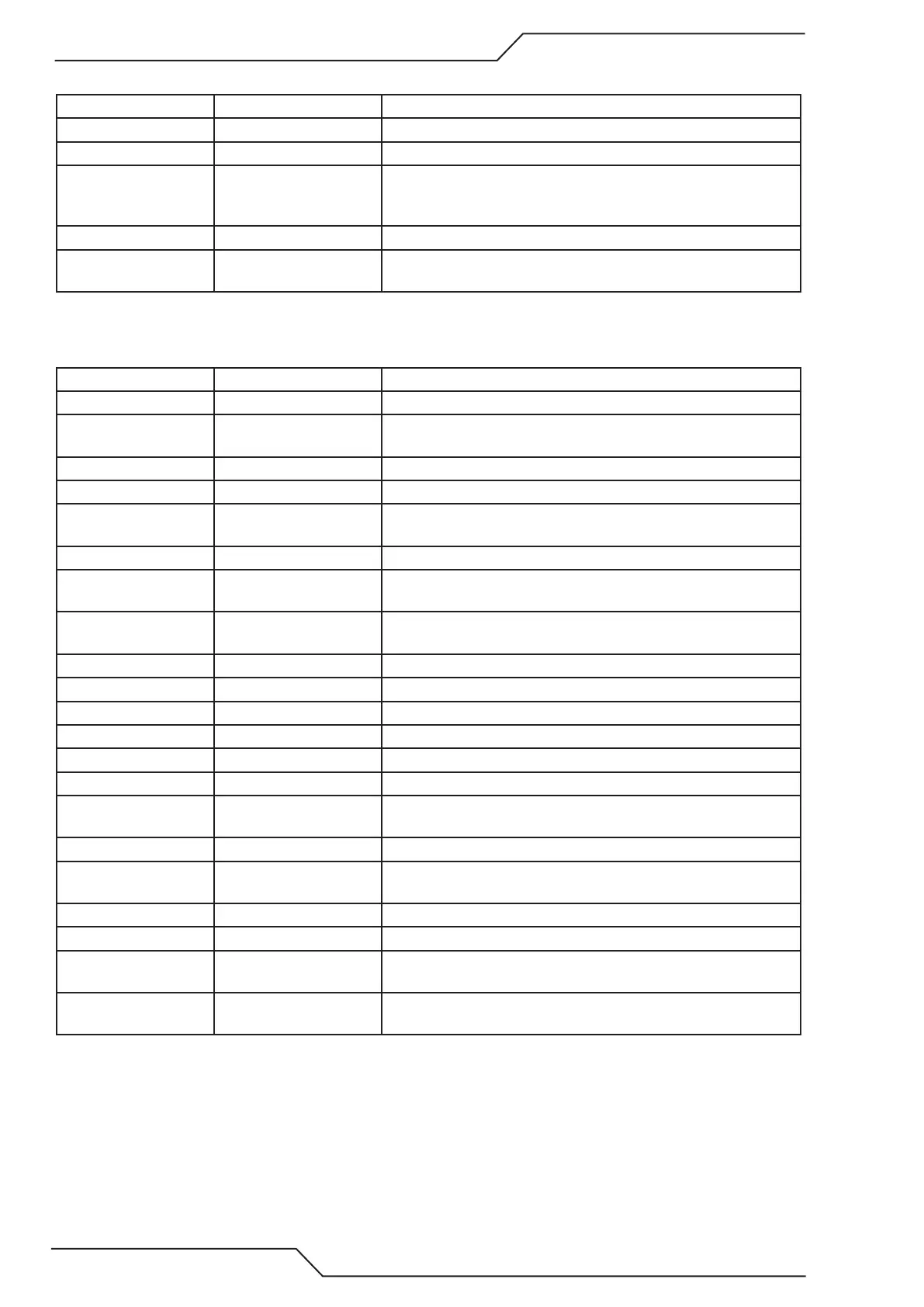

8.2.2 Boot and Power Issues

Problem Cause What to check

Unit will not power up No main power Measure 24VDC power input, replace power supply.

Poor power connection Check for proper power connector connection.

Over current fuse tripped Remove all cables, leave power off for 1min. Connect only the

power cable and try to boot. If CNC powers up connect cables 1 at

a time to find out which one is causing the issue.

Unit will not boot to

windows

Bios settings lost Change correct bios settings. Bios settings at page “A.1

Bios settings” on page A-1

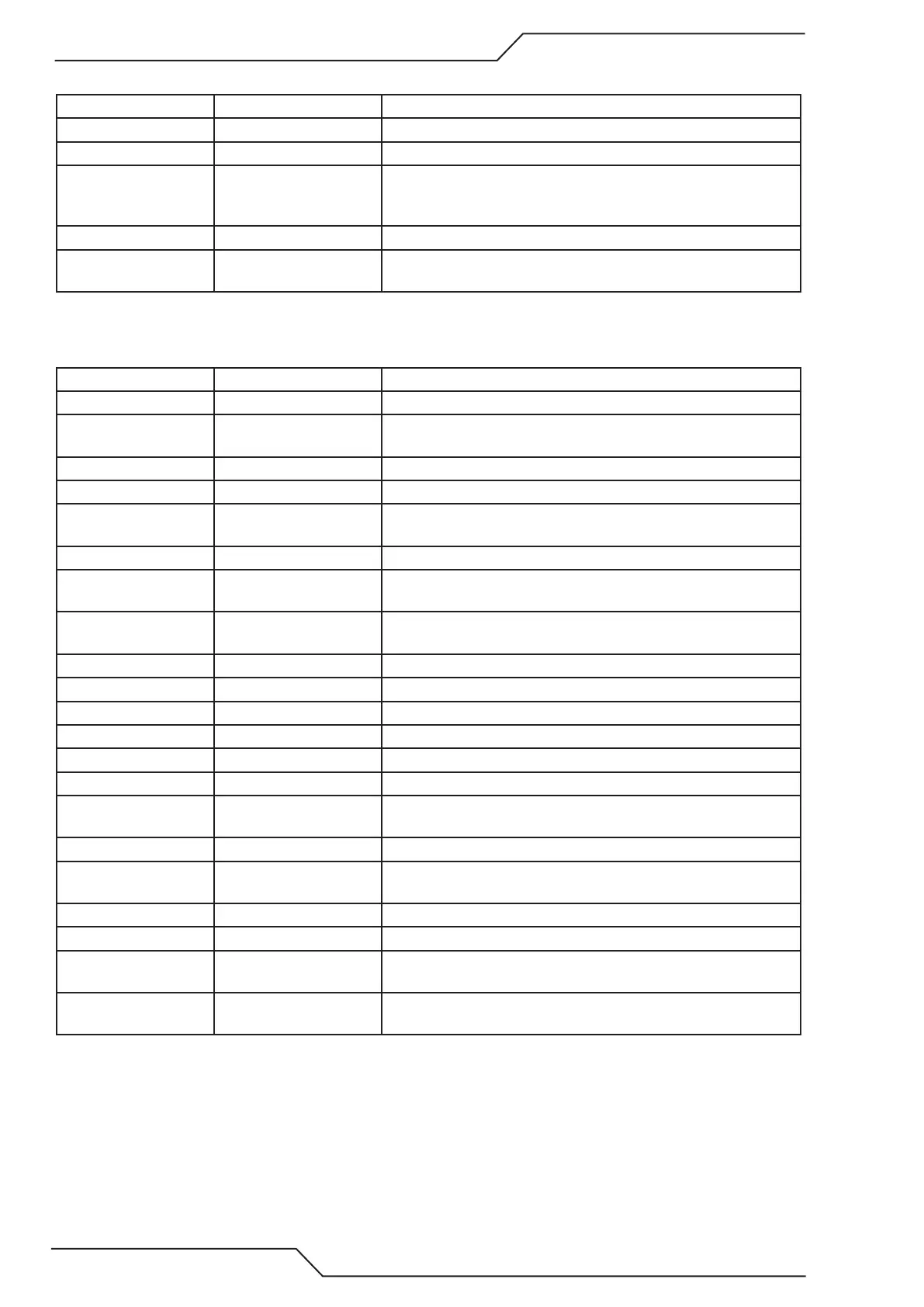

8.2.3 Piercing and Cutting Issues

Problem Cause What to check

Plasma will not pierce Worn out consumables Check consumables

Plasma start time set too

short

Check plasma start delay time

Plasma set to off Check plasma button is on Auto

Plasma starts but

crashes to plate

Worn out consumables Check consumables

AVC set too low Check arc voltage setting

Bad grounding Check for proper grounding to star ground from CNC chassis and

plasma work cable

Plasma arc lost in the

middle of a cut

Worn out consumables Check consumables

Error on plasma Check and clear plasma errors

Wrong gas pressures Check gas pressures

No AVC control AVC disabled Verify AVC chekbox is checked in iHC UI

Hold signal active Verify speed is set to 100%

Wrong arc voltage Wrong or bad consum-

ables

Check consumables

Wrong gas pressures Check plasma gas pressures

Bad grounding Check for proper grounding to star ground from CNC chassis and

plasma work cable

Coiled up work cable Make sure work cable is not coiled

Ohmic sensing does

not work

Poor connection Check for proper connection between voltage divider ohmic and

torch ohmic clip

Check for proper connection between torch ohmic clip and con-

sumable

Loading...

Loading...