iCNC Performance

7-24 iCNC SETUP Manual 0-5401

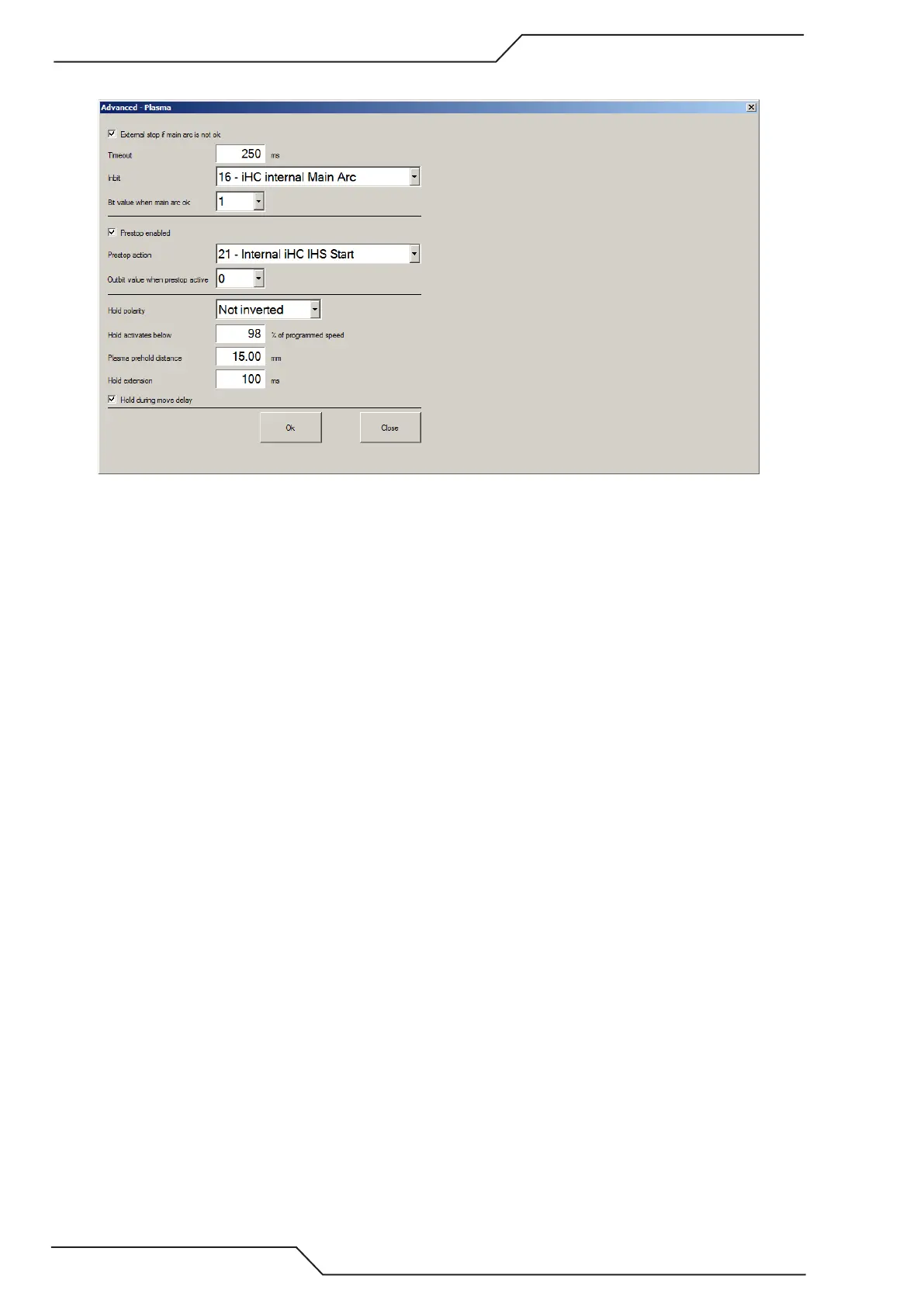

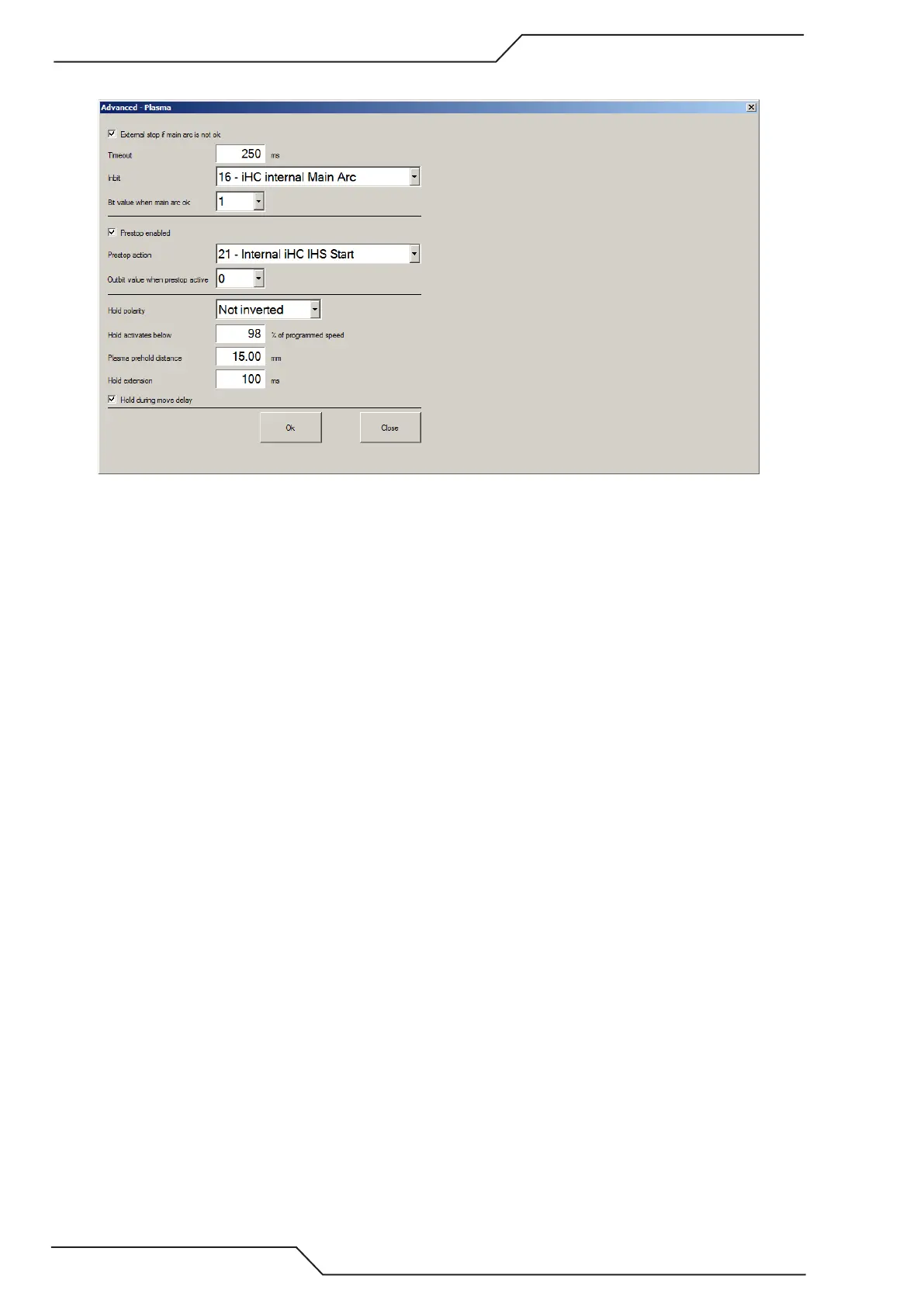

7.5.4 Advanced

These options are the same as Plasma advanced features.

• External stop if main arc is not ok Enable/Disable the feature. When enabled if plasma arc is lost during the cut process

CNC will stop motion, turn off cut process IOs and give a message that that arc has been lost during cutting.

• Time out Time out that the main arc input can be off before error message will be given. Used to filter out small jitters

in Inbit caused by example high frequency noise.

• Prestop enabled Enable/Disable feature

• Dropdown menu Outbit number that is controlled with prestop event.

• OutBit value when prestop active Is the outbit turned ON or OFF when prestop is triggered.

• Hold activates below Speed % where hold signal is activated..

• Plasma prehold distance Distance from the end of cut where hold signal is activated

• Hold extension Time extension to release hold signal. Used to give a bit of time for the arc to stabilize after example a

corner.

• Hold during MoveDelay Enable/Disable hold signal during piercing process (Start Delay 5).

• Hold polarity Hold signal polarity

• Enabled Enable/Disable feature

• OutBit Number Outbit number that is controlled with prestop event.

• OutBit value when prestop active Is the outbit value turned ON or OFF when prestop is triggered.

• Distance Distance from the cutting path end point when prestop is triggered.

Prestop is used to shut down the plasma arc before motion ends. As the current ramp down takes a small amount of

time before the arc actually extinguishes, prestop is used to turn the plasma off just before the actual cutting path ends.

This way you get a better end point quality when marking.

Loading...

Loading...