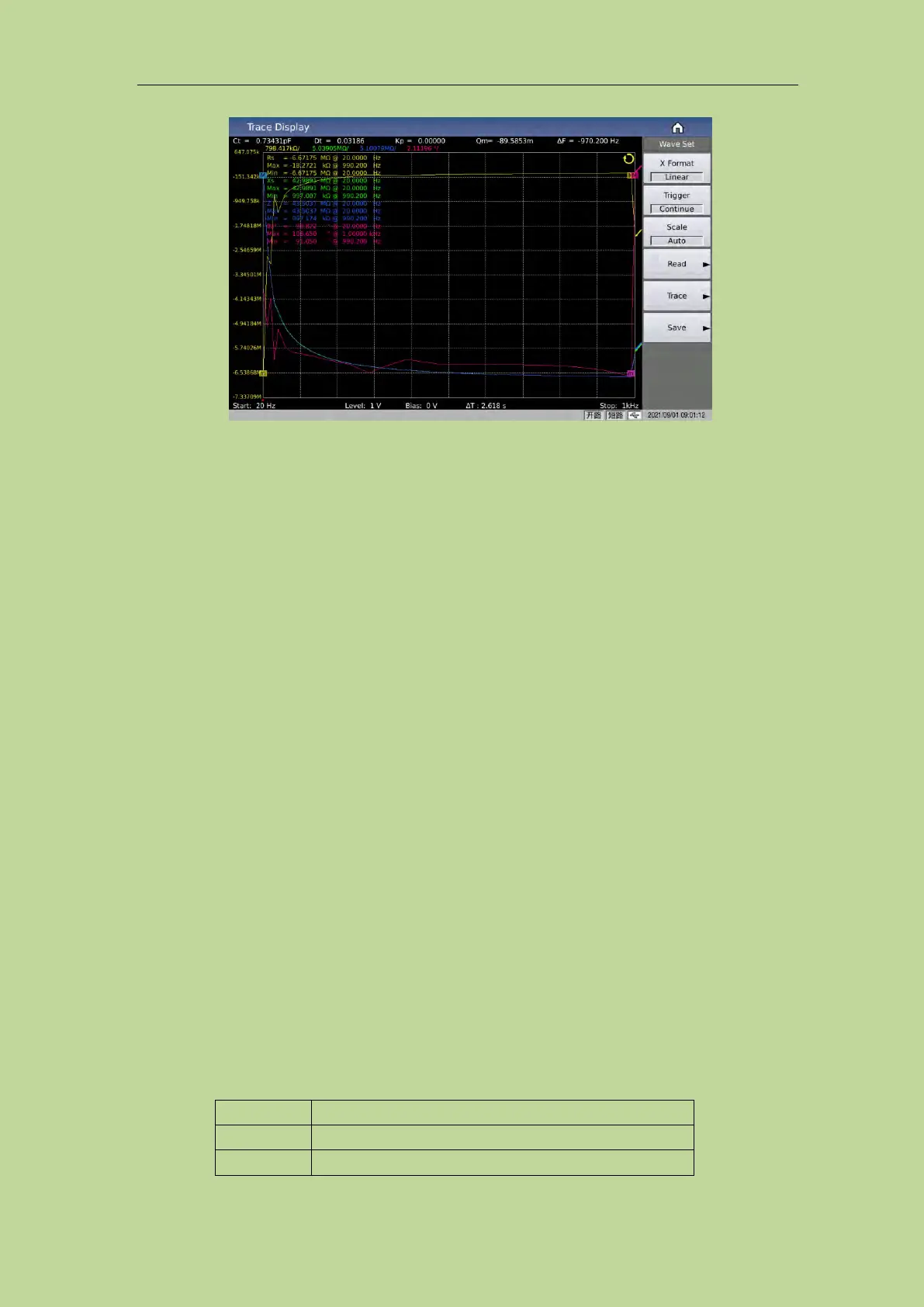

Figure 3-3-1 Trace display

In this display function page, each scan will perform automatic scan measurement of the tested

component at 51, 101, 201, 401 or 801 point frequency in a linear or logarithmic manner with

increasing conditions within the user preset mode range. Dynamic display of the response curve of

the main and secondary parameters of the component under test with the change of the mode

conditions on the LCD screen, the result of any point within the scanning range can be read on the

screen. Simultaneously, the maximum and minimum measurement values and corresponding test

conditions of the component under test within the scan range will be displayed.

Note: After the user has set the scanning conditions, the user must press the [Trigger] key on the

front panel to start scanning. Press the [Reset] key once to pause the test, and press it again to reset

and rescan.

3.3.1 Trigger

It is used to quickly set the trigger mode of the curve, refer to the trigger settup on the measurement

setting page.

3.3.2 Scale

It is used to automatically set the Y-axis coordinate range corresponding to the curve. In the case of

Auto, the Y-axis scale range will be dynamically adjusted with the size range of the test result to

ensure that the drawn curve is in the display range;

It is recommended that when the DUT is relatively stable, you can let the scale automatically select

a relatively suitable scale range, and then set it to be fixed, and then manually press the up and down

direction keys to fine-tune the display range according to the actual situation.

Parameter setting attributes: enumerated type.

Optional parameters:

The scale will adjust automatically

The scale is fixed, but can be adjusted manually

Loading...

Loading...