6-13 System Setup and Diagnostics

Diagnostic Checklists

Trio Motion Technology

Diagnostic Checklists

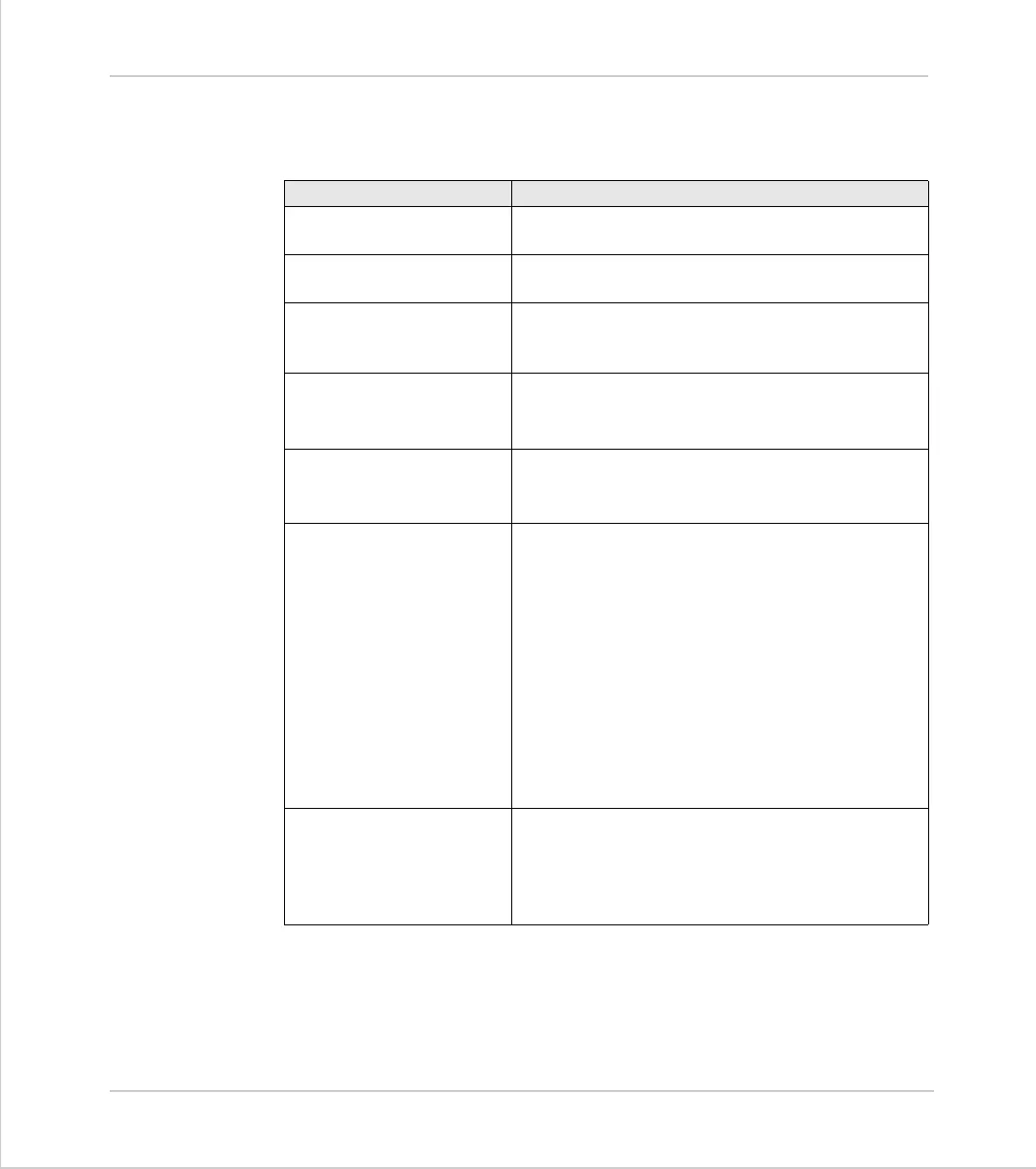

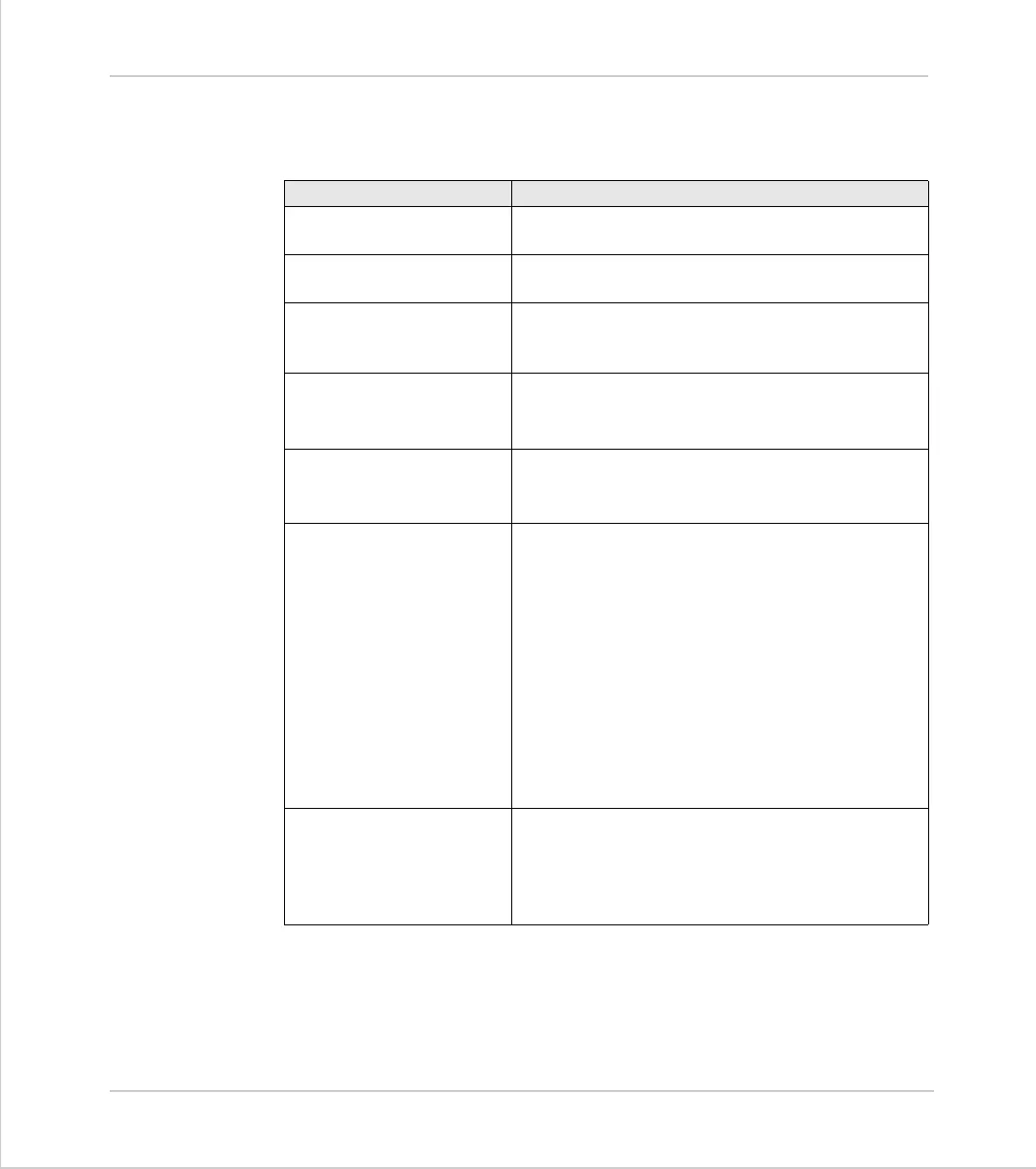

Problem Potential reasons

No Status LEDs on any mod-

ule

• Power Supply

LEDs lit on Master but not

on other modules

• Ribbon cable / Bank select switch

OK LED ON &

Status LED flashing

• Following error on at least one axis. The axis

demand position and measured position

exceed the programmed limit

Motor runs away without

issuing a move command

•tacho/drive polarity

• encoder/controller polarity

• gains (drive and/or controller)

Motor runs away upon issu-

ing a move command

• tacho feedback

• encoder feedback

• gains (drive and/or controller)

Motor does not move upon

issuing a move command

• wiring (enables/inhibits/limits on drive and

controller)

• check status on all axes

•drive power

• feedhold applied

• speed, acceleration and/or deceleration set to

zero

• servo set off/watchdog set off

• gains (drive and/or controller)

• axis is already running a move which has not

completed - Check MTYPE and NTYPE

Axis goes out on following

error after a time

• speed being requested requires more than 10v

- check drive tacho gain and motor/ drive

speed characteristics.

• drive shutting down on current limit after a

time

Loading...

Loading...