Technical Description TITANUS MICRO·SENS

®

2 – 4 Data: 01/09 MS_A_02-a-en-e

steps of 0.1 %/m. The alarm is shown on the device via the alarm display

and forwarded to a connected fire alarm system (FAS).

By changing the delay time with the diagnosis tool, the forwarding of

alarms and faults can be set.

The intelligent LOGIC·SENS signal processing device serves to blank out

fire-like false alarms and ensures high false alarm safety.

Airflow monitoring An airflow sensor checks the connected pipe system for breaks and

blockages.

Depending on the design of the pipe system and the setting on the air-

flow sensor, the blockage of just one aspiration aperture can be picked

up. The airflow monitoring is temperature-compensated and can be

made air pressure-dependent.

At the end of the adjustable delay time, the fault is shown on the smoke

detection system and a corresponding message is forwarded to the

central fire alarm point via a contact. The monitoring windows can be

adjusted to the environmental conditions.

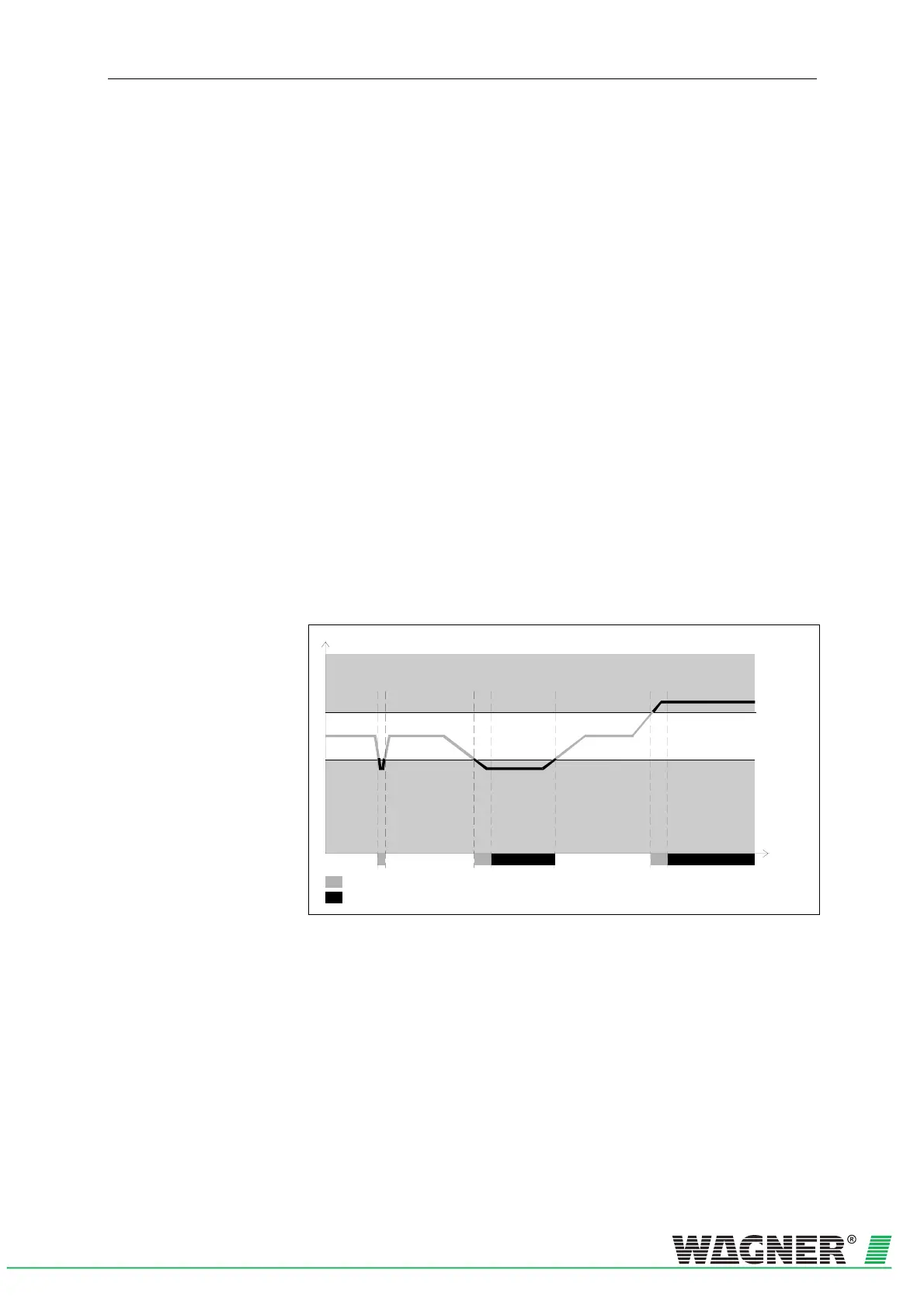

The principle of the airflow sensor signalling process can be seen in

0HFig.

2.6 .

Device monitoring The detection unit is monitored for dirt and signal fault. Any fault which

occurs is displayed at the TITANUS MICRO·SENS

®

and can be for-

warded to the FAS via a contact.

Signal from the air flow sensor

Mo nitoring

window

Time

Blockage

Break

Airflow too high

Delay time

Fault message

Airflow normal

Airflow

too low

Fig. 2.6: Example signal pattern in the airflow sensor during faults

Airflow adjustment Airflow adjustment on the TITANUS MICRO·SENS

®

is fully automatic

when the detection unit is inserted in the device base, if previously the

Jumper X4 had been changed. This plug & play reduces the time needed

for commissioning to a minimum. It is also possible, however, to adjust

the airflow using the DIAG 3 diagnosis tool. This means the initialisation

phase can be carried out in an air pressure-dependent or air pressure-

independent manner.

Loading...

Loading...