MACHINING PROGRAM 4

4-75

A. Using upper turret and HD1 for turning, lower turret and HD2 is using for turning

1. Sample program

G109L1

M901

M202

G00G18G90G95G54G96

G40G49G80G67G69

G91G28X0

G28Z0

G28Y0

G28B0

T001T002M06

G91G28X0

G28Y0

G28Z0

M108

G90G53B90.

M107

M511

G92S2000R1

G96M203S150R1

G10.9X1

M08

G90G43G0X250.0Y0Z0.0 H1P1

X100.

G275R1.0

G275X-5.Z0.0P5.Q0.F0.2

G0X100.0Z0.0

G80

G40

M513

M205

M09

G90G0W0.

M950

T002T003M06

G91G28X0

G28Y0

G28Z0

M108

G90G53B0

M107

G97M203S2000

G10.9X1

M08

M951

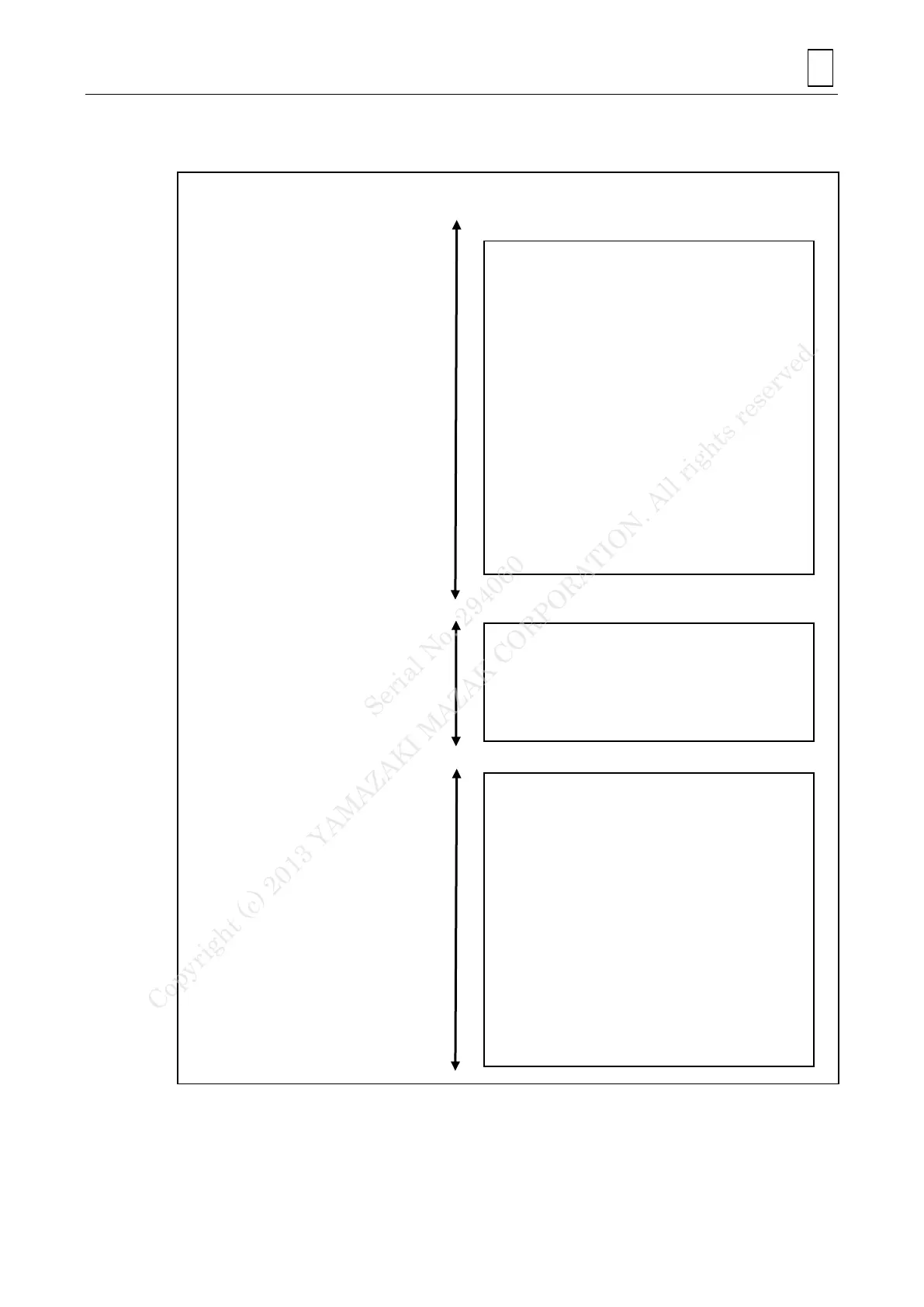

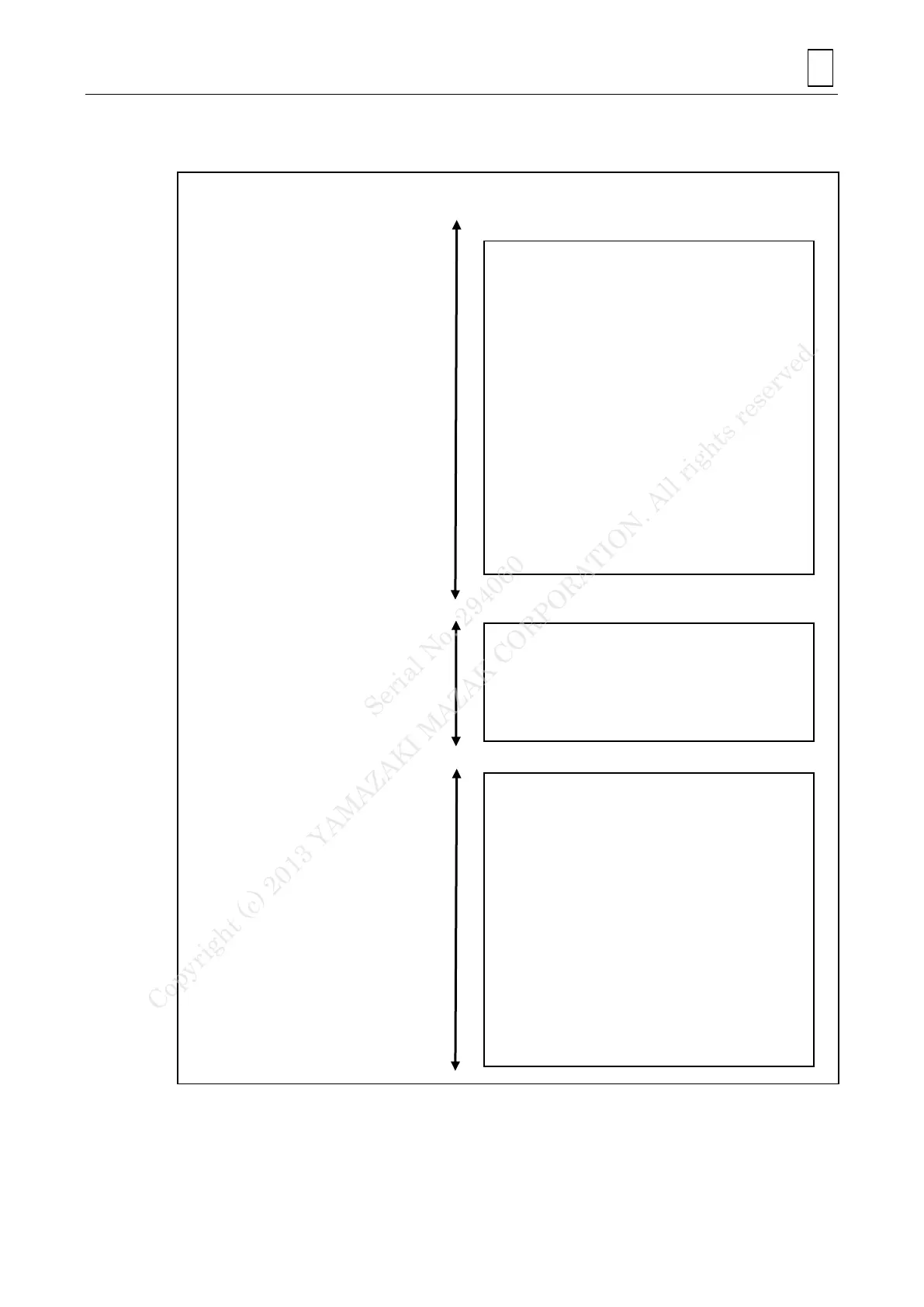

(Upper turret: HD1- Turning, Lower turret: HD2- Turning (1/2))

jiku

Preparation motion for machining

G109L1: Upper turret selection

M901: HD1 spindle selection

M202: C-axis disconnect / turning mode

G95: Feed per revolution

G96: Constant surface speed control ON

T001M06: Tool change (TNo.01)

B-axis positioning

M107: B-axis clamping

G92S2000: Spindle speed range setting

G96S2000: Surface speed 150 m/min

R1: Set the HD1

M203: Turning spindle1 forward rotation

G10.9X1: Diameter data input mode

M08: Flood coolant ON

Machining motion

M511 (Instructs in Preparation motion for

machining):

Turning spindle synchronized rotation

G275: Transverse cut-off cycle

Operation of tie

M513: Turning spindle synchronized

rotation OFF

M205: Turning spindle1 Rotation stop

M09: All coolants OFF

W-axis positioning

T002M06: Tool change (TNo.02)

B-axis positioning

M107: B-axis clamping

G97S2000: Rotation speed 2000 min

-1

M203: Turning spindle1 forward rotation

G10.9X1: Diameter data input mode

M08: Flood coolant ON

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...