4 MACHINING PROGRAM

4-20

B. Program composition

C. Parameter setting

The main parameter of processing is described.

The table shows the standard parameter and setting set in this manual.

Parameter setting

Moving axes by using G49 (tool length offset cancel) in G43 (tool

length offset) mode Invalid

Return distance in Z-axis at wall during rough cutting in bar

machining or in corner machining

Cutting depth in the composite-type fixed cycle

Note : SU103 and SU102 are to be used respectively as arguments R (SU102) and U

(SU103), when R or U in G271 is omitted.

G00G90G43XxYy Zz HhP1

M250

G271UdRr

G271PpQqUuWwFf

NpG41(G42) DdG0Xx Zz

(Finishing contour)

NqXxZz

G0XxZz

G40G80

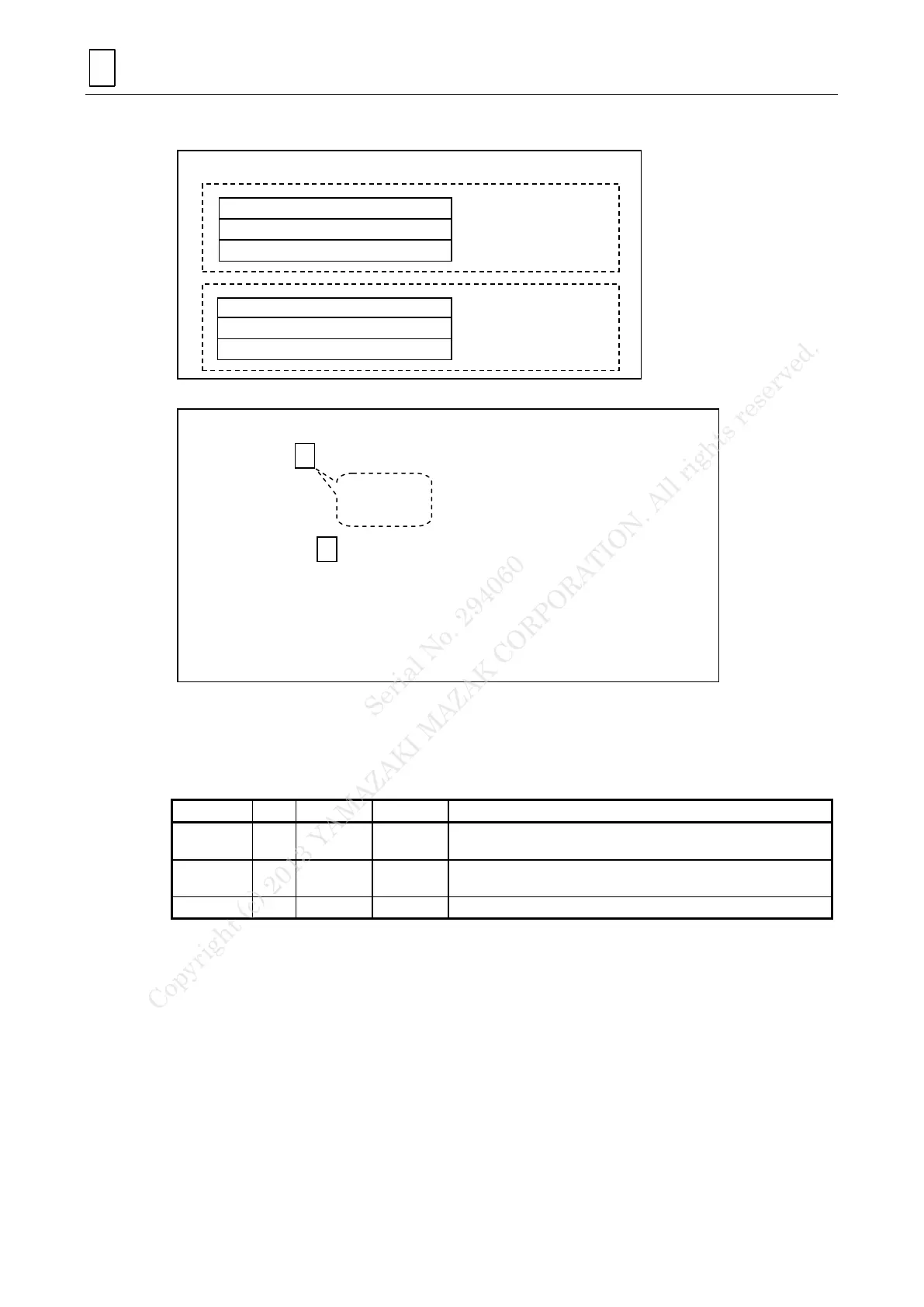

Machining motion of program component –Turning machining-

--- Tool length offset (for turning tool)

This point will be a cycle start point.

--- Spindle speed attainment check

--- G271 input( details shown on other page)

--- G271 input

--- Head block for finishing contour

Nose radius compensation

--- Turning for work shape

--- End block for finishing contour

--- Escape

--- Nose radius compensation OFF

Fixed cycle OFF

Same value

with cycle

start block

Instruction in

preparation motion

for machining

Instruction in

machining motion

Program composition element

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...