SUPPLEMENT 5

5-49

10. G-code (Group12)

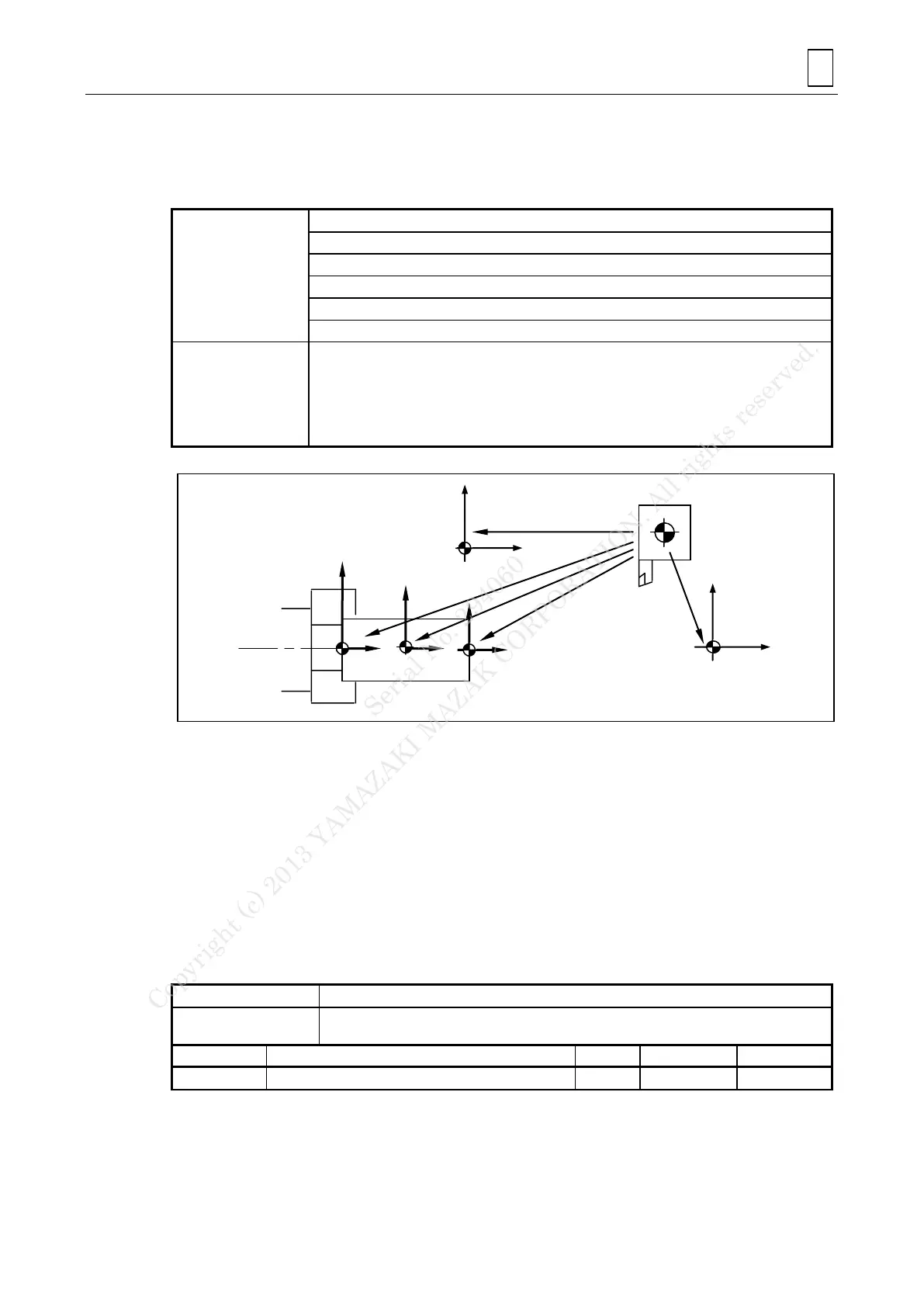

A. Selection of workpiece coordinate system

1. Command

Workpiece coordinate system 1

Workpiece coordinate system 2

Workpiece coordinate system 3

Workpiece coordinate system 4

Workpiece coordinate system 5

Workpiece coordinate system 6

Commanding the above permits selection/change of one of six coordinate systems specified

beforehand that are agreed with the machine. By this command, subsequent axis commands

are used as positioning at selected workpiece coordinate system until the reset key is

pressed.

For the six workpiece coordinate systems, set the distance on each axis from the machine

zero point to the zero point of each coordinate system on the WORK OFFSET display.

2. Notes

The distance when coordinate system is moved by G92 is added subsequently to all

workpiece zero point offset values. For example, when coordinate system is moved by

“G92 X_ Z_” command in the selection of G54, G55 to G59 also move by the same

distance. Therefore, take care when having changed to G55.

The coordinate system cannot be established exactly for the C-axis by a command of

G54 to G59 if it is given with the C-axis not being connected. Do not fail, therefore, to

select the milling mode (for C-axis connection) before entering G54 to G59 as required

for the C-axis.

B. Additional workpiece coordinate system setting and selection

1. Command

In addition to the six standard systems G54 to G59, up to 300 sets of workpiece origin data

can be used to facilitate program creation.

Number of additional workpiece coordinate system

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...