MACHINING PROGRAM 4

4-11

7. B-axis positioning

Perform B-axis positioning.

If the B axis is already indexed, it is not necessary to command B positioning here.

For turning, command B axis clamp (Turning spindle does not turn if B axis is being unclamped).

8. Spindle rotation command

Command a rotation for Turning-Spindle/Milling-Spindle. M-codes are shown in the figure below.

S-address means rotational speed (G97) or surface speed (G96) by modal G-code group 17.

In case of Mill-machining, G96 cannot be used.

When G96 is used, command G92 to set the maximum min

-1

.

Milling Spindle (G109L1)

M03: Start of forward

milling spindle rotation

M04: Start of reverse

milling spindle rotation

(M05: Stop of milling spindle

rotation)

Turning spindle 1

M203: Turning Spindle 1

start of forward

rotation

M204: Turning Spindle 1

start of reverse

rotation

(M205: Turning spindle 1

Rotation stop)

Turning spindle 2

M303: Turning spindle 2

start forward rotation

M304: Turning spindle 2

start reverse rotation

(M305: Turning spindle 2 Rotation

stop)

Milling spindle (G109L2)

M03: Start of forward

milling spindle rotation

M04: Start of reverse

milling spindle rotation

(M05: Stop of milling spindle rotation)

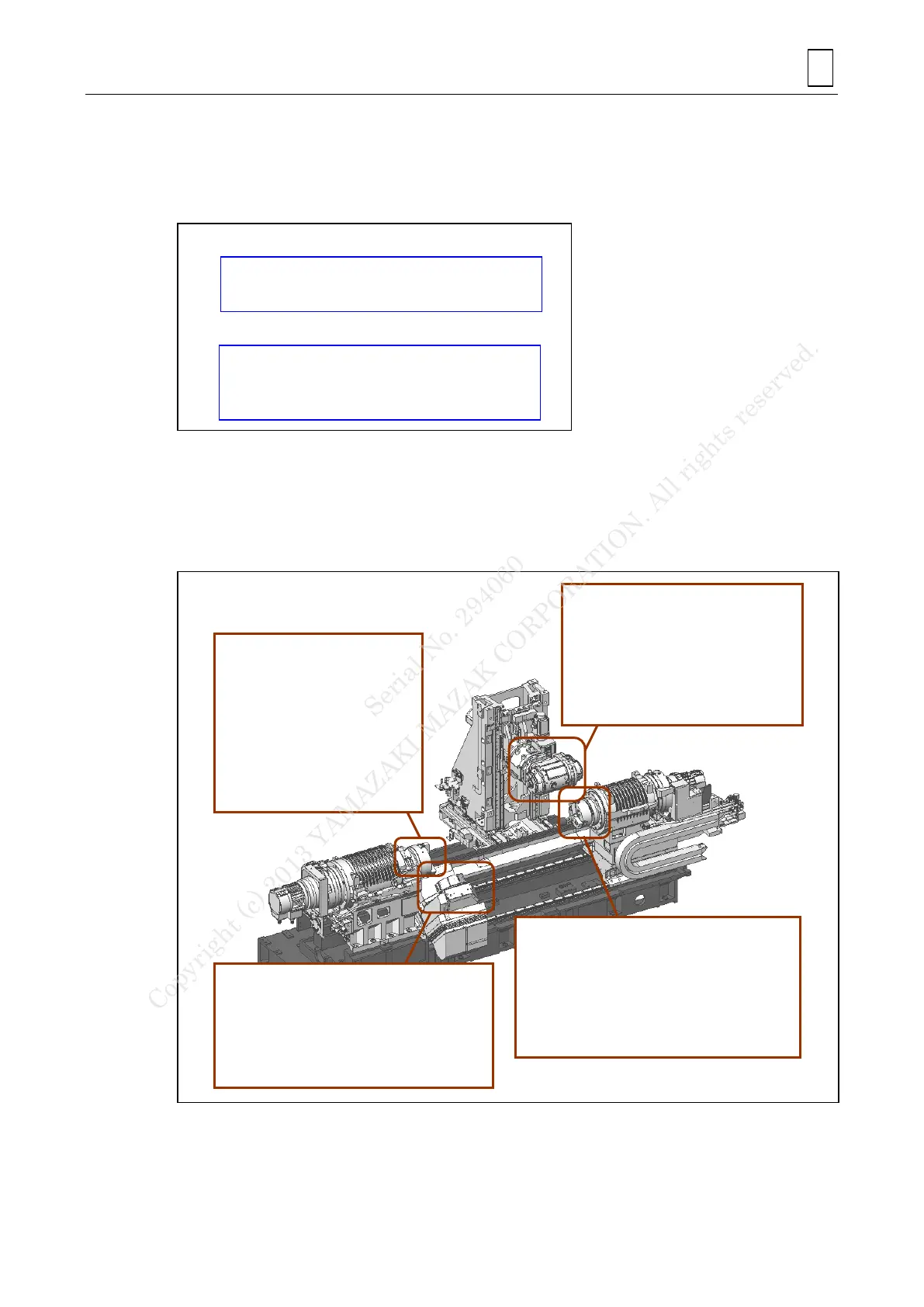

M108 (B-axis unclamping)

G90G53B***.** (B-axis positioning)

M108 (B-axis unclamping)

G90G53B***.** (B-axis positioning)

M107 (B-axis clamping)

B-axis positioning(In case of turning)

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...