5 SUPPLEMENT

5-12

2. Sample program

example 1)

G91 G28 X0 Z0 Y0

G92 X0 Z0 Y0

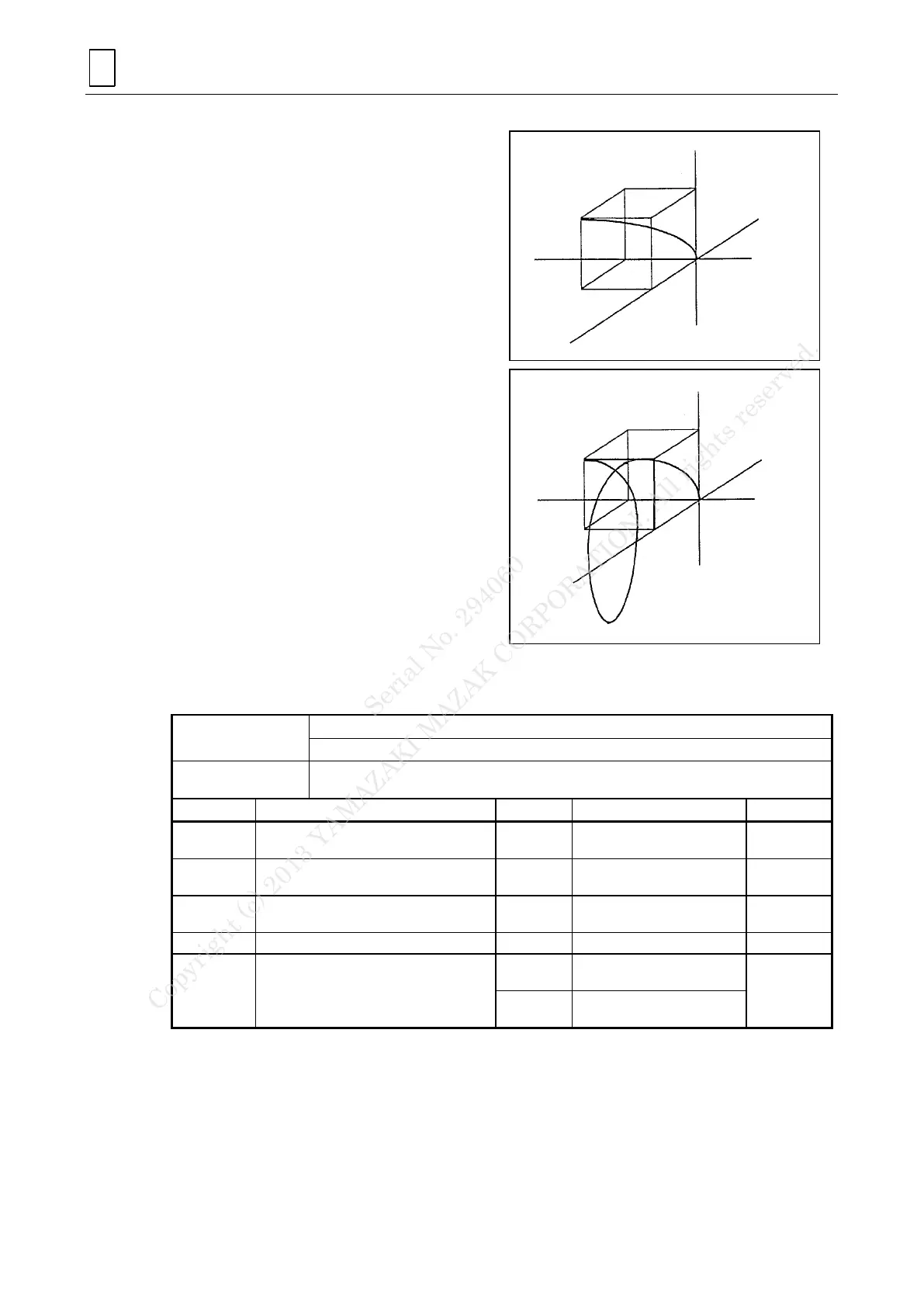

G17 G03 X50. Y50. Z-50. R50. F1000

example 2)

G91 G28 X0 Z0 Y0

G92 X0 Z0 Y0

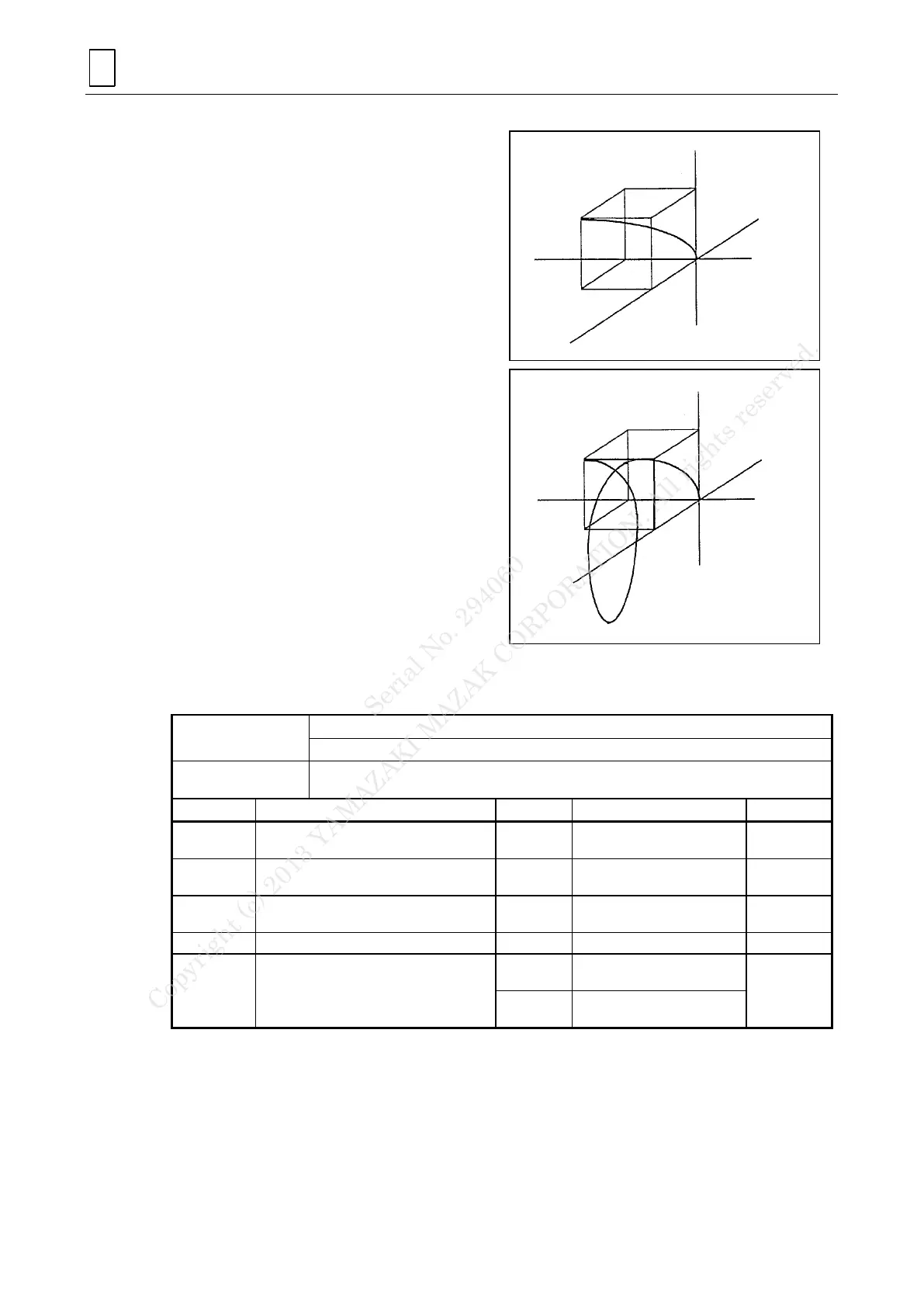

G17 G03 X50. Y50. Z-50. R50. P2 F1000

E. Threading

1. Command

The G32 command controls the feedrate of the tool in synchronization with the spindle

rotation and so this enables both the straight and the continuous thread cutting.

Thread ending point addresses and

coordinates (Z-axis)

±99999.9999 (mm)

±9999.99999 (in)

Thread ending point addresses and

coordinates (X-axis)

±99999.9999 (mm)

±9999.99999 (in)

Lead of long axis (axis of which moving

distance is the longest) direction

0.001 to 999.999 (mm)

0.0001 to 99.9999 (in)

Shift angle of threading start

Lead of long axis (axis of which moving

distance is the longest) direction (Note)

0.00001 to 999.99999 (mm)

0.000001 to 99.999999 (in)

0.01 to 999.999 (mm)

0.001 to 99.9999 (in)

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...