SUPPLEMENT 5

5-7

2. Sample program

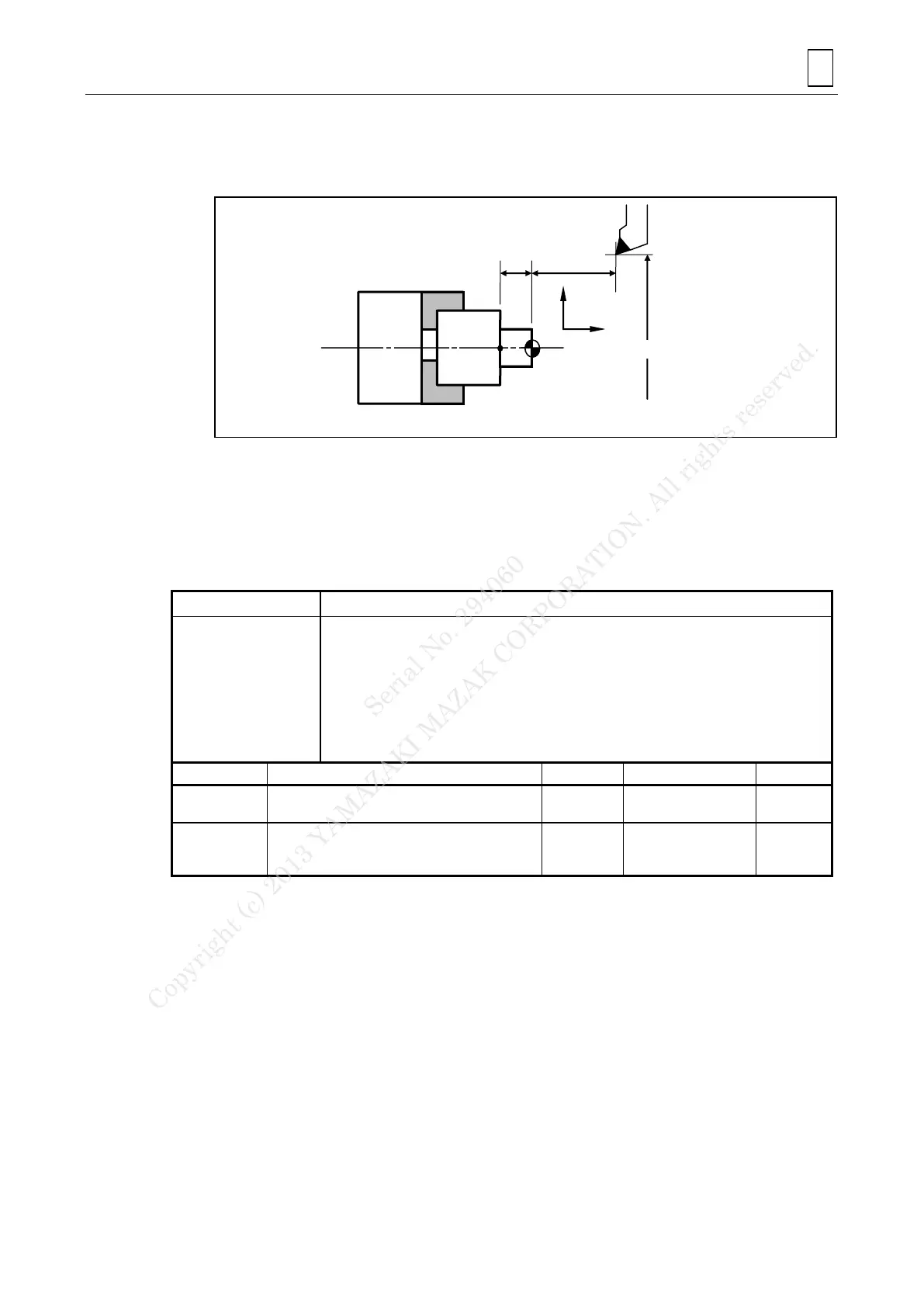

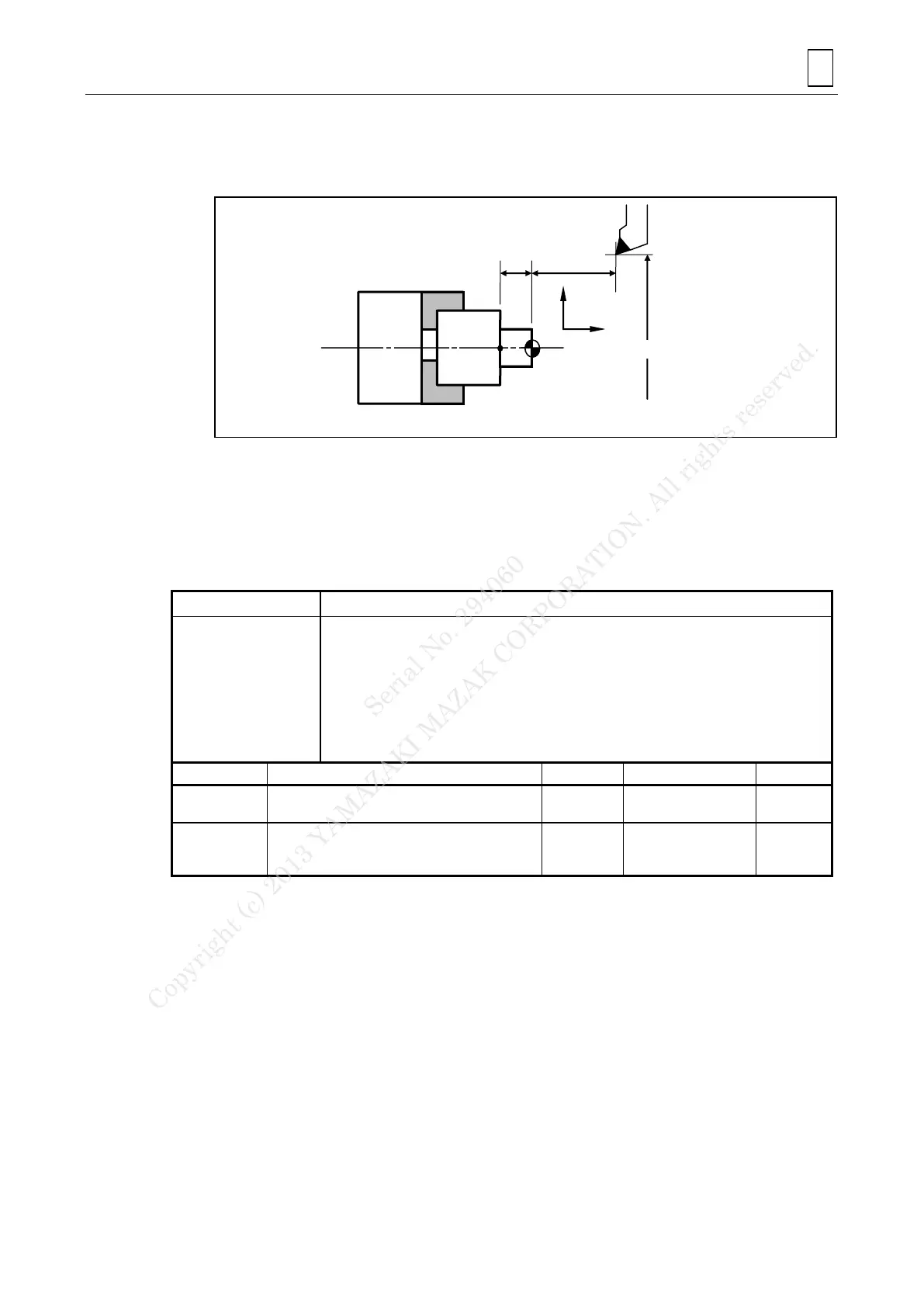

G92 X350.0 Z300.0 (For setting a coordinate system with “workpiece zero point” as zero

point)

G92 X350.0 Z350.0 (For setting a coordinate system with point “A” as zero point)

3. Notes

The G92 function code causes the maximum or minimum spindle speed to be set

when it is used with argument S or Q.

Nose/Tool radius compensation is temporarily cancelled by G92.

I. Selection of machine coordinate system

1. Command

The above command permits moving the tool to the commanded position in the machine

coordinate system at the rate of rapid traverse. G53 is valid only for the commanded block.

To move a tool to the position specifically set for the machine including tool change

position, command G53 using the machine coordinate system. A base point on the

machine is referred to as the machine zero point. Machine zero point depends on machine

specifications. A coordinate system using machine zero point as the zero point of

coordinate system is referred to as machine coordinate system. The tool cannot always

move to the machine zero point. In some cases, machine zero point is set at a position to

which the tool cannot move.

The position in the machine coordinate system

(X, Y, Z-axis)

±99999.9999 (mm)

±9999.99999 (in)

The position in the machine coordinate system

(Additional axis)

±99999.9999(mm)

±9999.99999 (in)

±99999.9999 (°)

2. Notes

G53 with incremental command can be commanded, but it is meaningless.

Virtual axes cannot be commanded.

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...