SUPPLEMENT 5

5-61

17. G-code (Group27)

A. Workpiece setup error correction

1. Command

This function is provided to compensate for the error in setting a workpiece easily, without

having to rewrite the program section for describing the machining contour, by modifying the

workpiece coordinate system according to the error in question.

Number of the data set for workpiece setup error correction

2. Notes

Be sure to enter the G54.4 command (for selection as well as for cancellation)

independently.

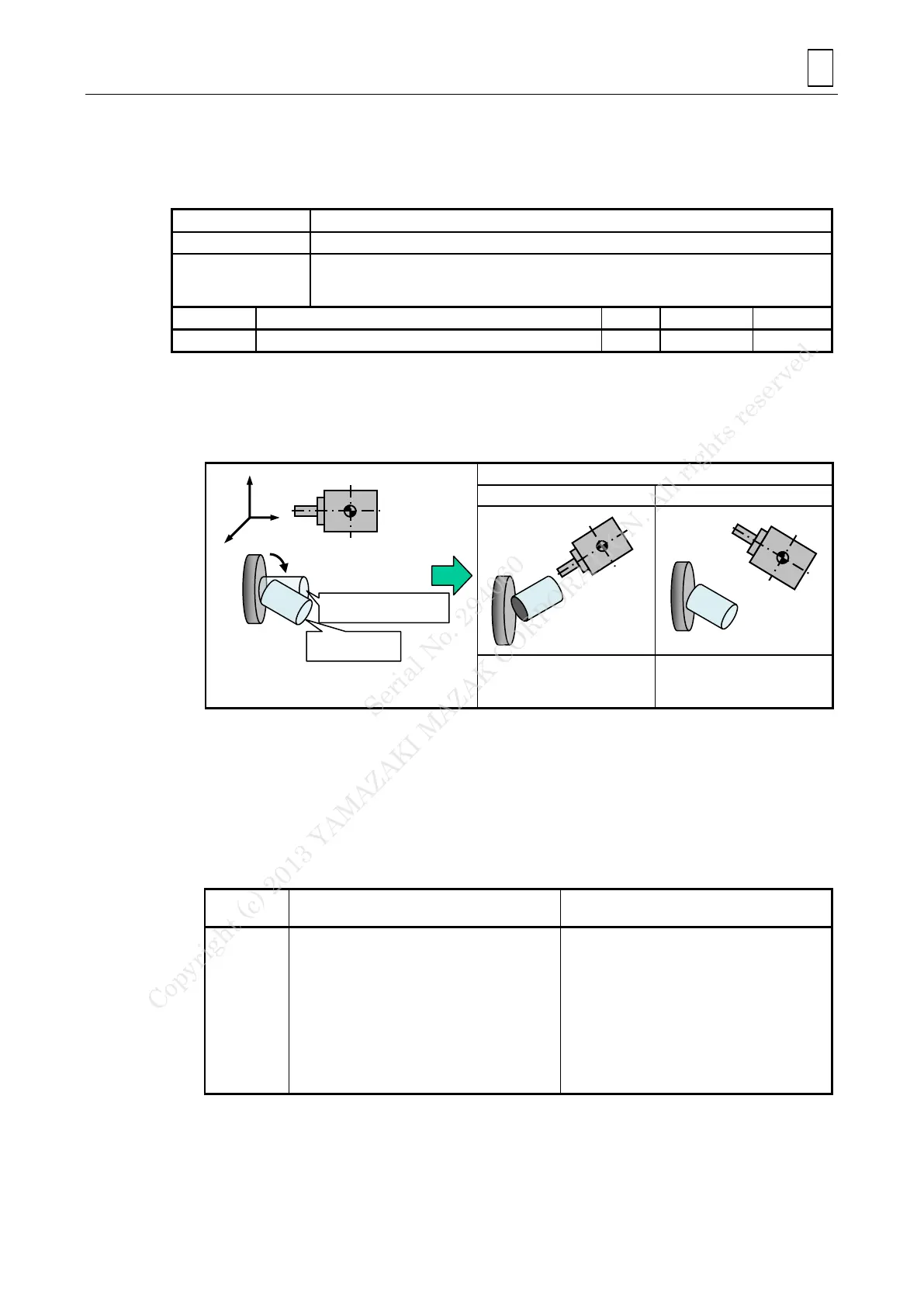

The correction of tool attitude in question can be done in general by using either of the

two possible pairs of angles on the rotational axes concerned.

Pairs of angular positions for tool attitude correction

With a positive B-axis angle

With a negative B-axis angle

POSITION MACHINE

B 0. B 30.

C 0. C 180.

POSITION MACHINE

B 0. B –30.

C 0. C 0.

The selection between the two pairs is done as follows.

1. For the selection block with G54.4:

Selected is the pair for a method which requires smaller distance of angular motion

on the table’s rotational axis (for five-axis control machines of mixed type).

2. For all the other blocks:

The selection is done according to the setting of parameter F162 bit 1

(Type of passage through singular point for tool tip point control).

Selected is the pair for a method which results

in the angle of the tool’s rotational axis

obtaining the same sign as its initial position

(position at the startup by a G54.4 command).

Note: When the initial position on the tool’s

rotational axis is equal to 0, then

decision is made for the pair whose

angle of the tool’s rotational axis has

the same sign as the wider side of its

axis stroke.

Selected is the pair for a method which

requires smaller distance of angular motion on

the table’s rotational axis.

Programmed

command:

B = 0°

C = 0°

Error around Y-axis

Δb = -30°

Real workpiece

setup position

Ideal position (as on the

machining drawing)

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...