MACHINING PROGRAM 4

4-29

B. Program composition

C. Parameter setting

The main parameter of processing is described.

The table shows the standard parameter and setting set in this manual.

Parameter setting

Programming type for inclined-surface machining Type A

Moving axes by using G49 (tool length offset cancel) in G43 (tool

length offset) mode Invalid

Selection of table rotary axis reference position for inclined-surface

machining Table rotary axis 0-degree position as the reference

Note 1: Type A: Combined use with the other 5-axis machining functions, and cannot allow

interruption during Inclined-Plane machining

Note 2: Type B: Combined cannot use with the other 5-axis machining functions, and allowing

interruption during Inclined-Plane machining

G61.1

M108M212

G68.2 P1XxYyZzIiJjKk

G53.1

M107M210

G90G43XxYyZzHh

G1XxYyZzFf

(Machining nontour)

G0XxYyZz

G69

G64

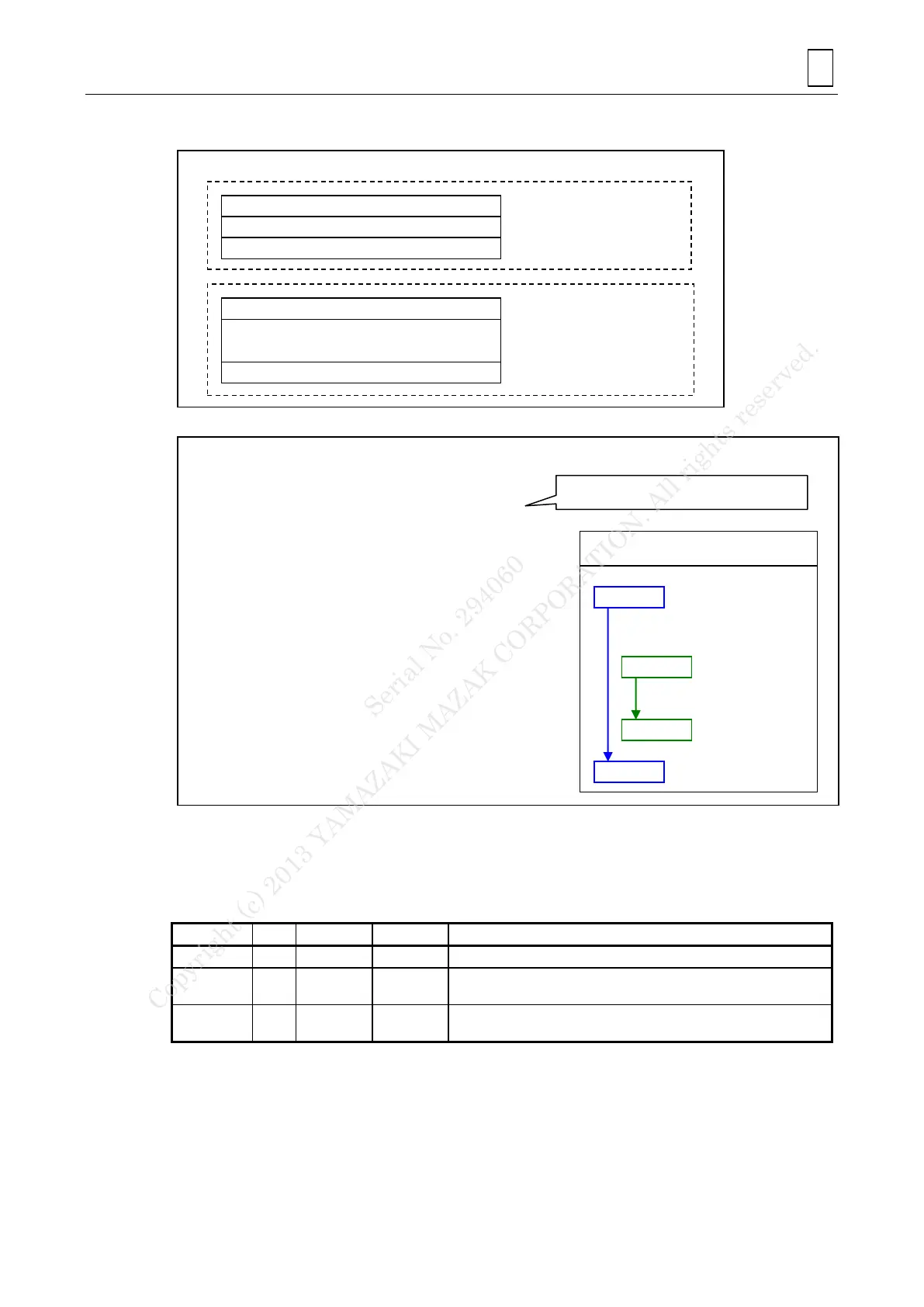

Machining motion of program composition –Inclined plane machining-

--- Geometry compensation

--- Rotation axes unclamping

--- Inclined-plane machining

Using roll, pitch, and yaw angle

--- Tool-angle direction control

--- Rotation axes unclamping

--- Tool length offset

--- Head block for machining contour

--- machining contour

--- Escape

--- Inclined-plane machining

--- Geometry compensation OFF

Command G68.2 while in the G61.1

mode.

BC axes need to be unclamped prior to

G53.1. as G53.1 indexes the rotary axes.

Instruction in

preparation motion

for machining

Instruction in

machining motion

Inclined-plane machining

Roll, pitch, and yaw angle

Program composition element

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...