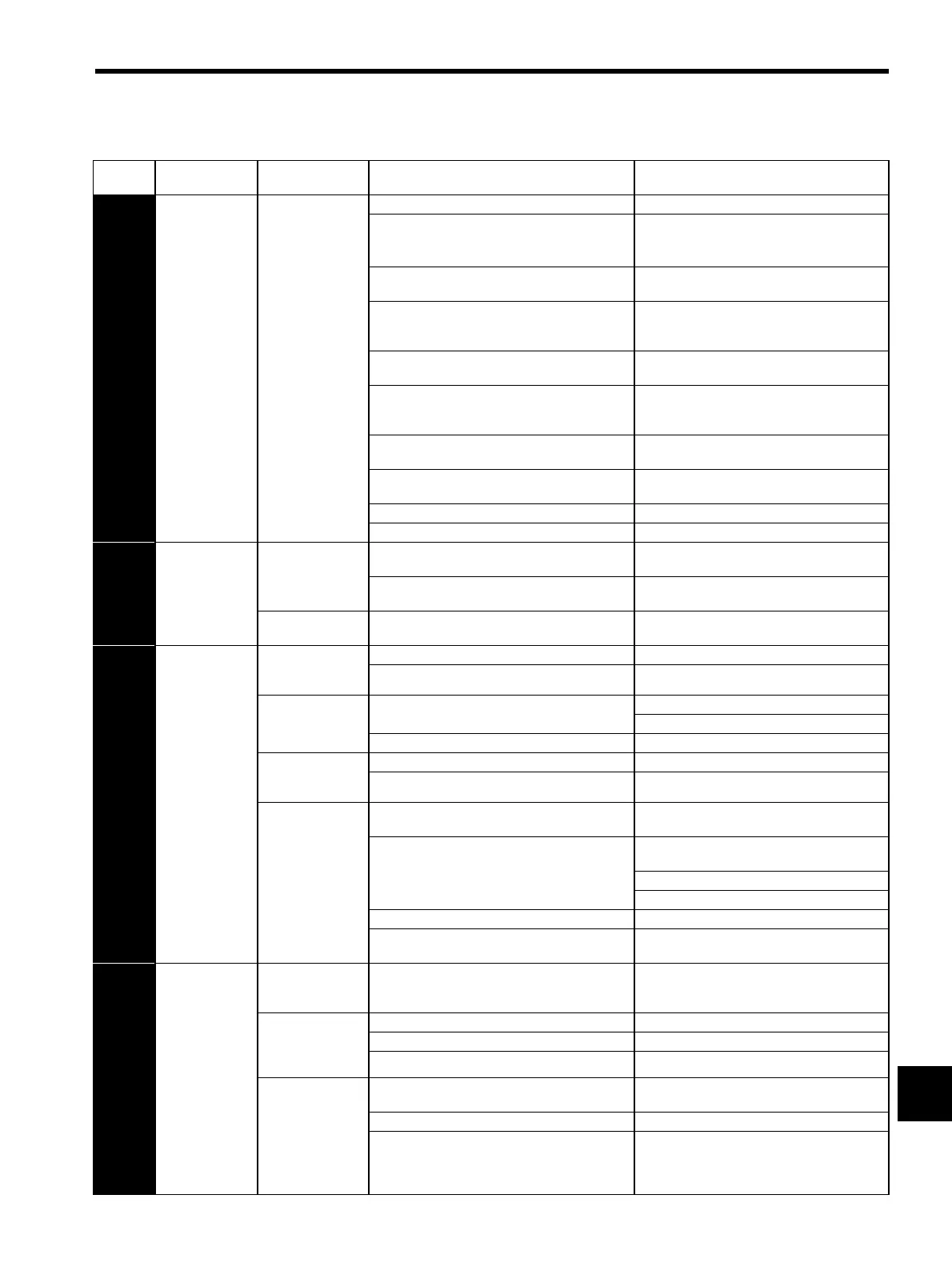

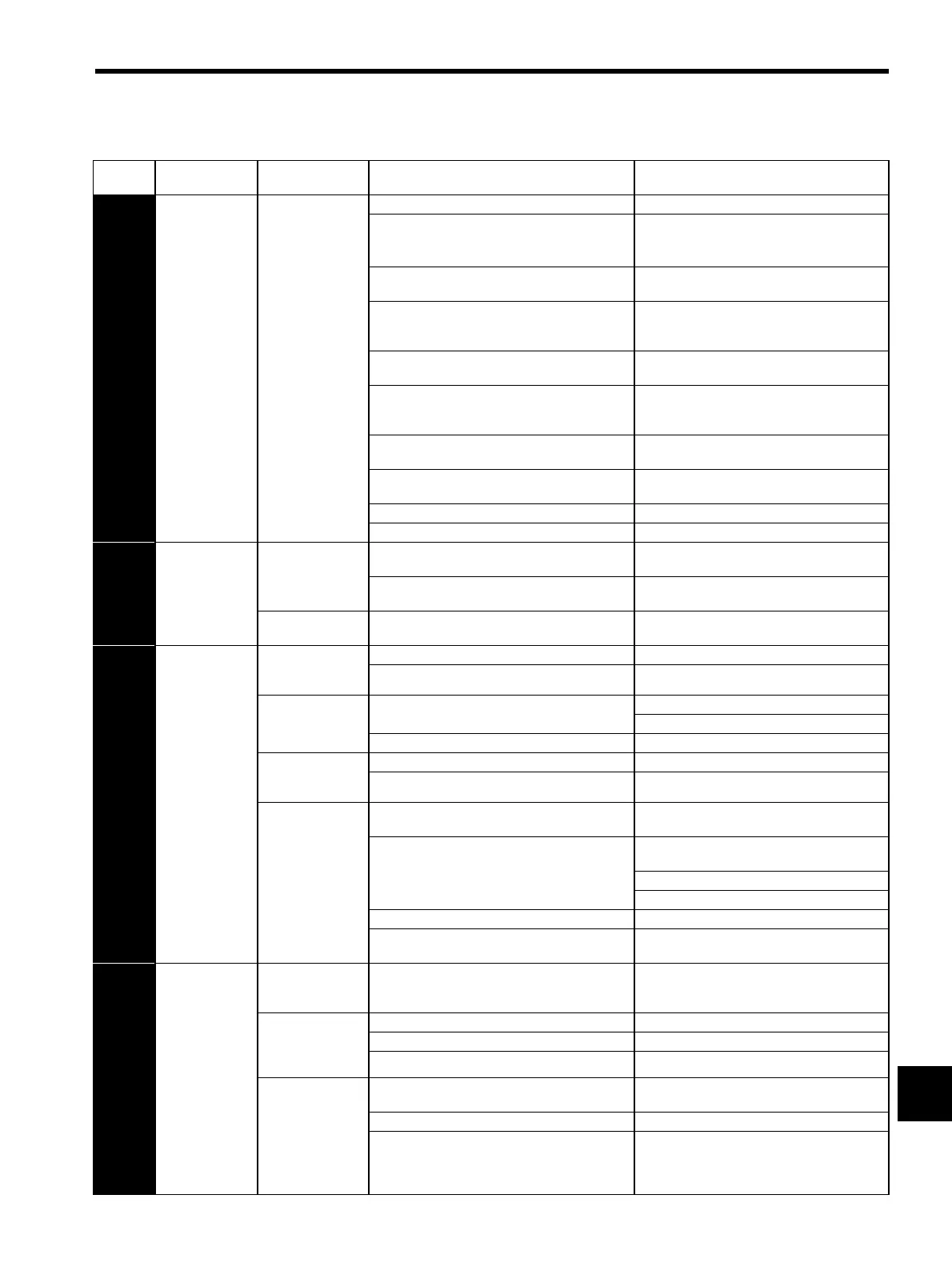

11.1 Troubleshooting

11-13

11

A.Cb

Encoder Echo-

back Error

Occurred when the

control power sup-

ply was turned ON

or during operation.

The encoder wiring and contact are incorrect. Correct the encoder wiring.

Noise interference occurred due to incorrect encoder

cable specifications.

Use tinned annealed copper twisted-pair or

twisted-pair shielded wire with a core of at least

0.12 mm

2

(0.0002 in

2

).

Noise interference occurred because the wiring dis-

tance for the encoder cable is too long.

The wiring distance must be 20m (65.6 ft) max.

Noise interference occurred on the signal line,

because the encoder cable is bent and the sheath is

damaged.

Correct the encoder cable layout.

The encoder cable is bundled with a high-current

line or near a high-current line.

Correct the encoder cable layout so that no surge

is applied.

The FG electrical potential varies because of the

influence from such machines on the servomotor

side as welders.

Ground the machine separately from PG side FG.

Noise interference occurred on the signal line from

the encoder.

Take measures against noise for the encoder wir-

ing.

Excessive vibration and shocks to the encoder was

applied.

Reduce the machine vibration or mount the servo-

motor securely.

An encoder fault occurred. Replace the servomotor.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

A.CC

Multiturn Limit

Disagreement

Occurred when the

control power sup-

ply was turned ON.

The parameter settings for the SERVOPACK are

incorrect.

Correct the setting of Pn205 (0 to 65535).

The multiturn limit value for the encoder is not set or

was changed.

Execute Fn013 at the occurrence of alarm.

Occurred during

normal operation.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

A.d0

Position Error

Pulse Overflow

(In servo ON sta-

tus, the position

error pulses

exceed the over-

flow level set in

the parameter

Pn505.)

Occurred when the

control power sup-

ply was turned ON.

The overflow level (Pn505) is incorrect. Make the value set in the Pn505 to other than 0.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred at the ser-

vomotor high-speed

rotation.

The contact in the servomotor U, V, and W wirings

is faulty.

Correct the servomotor wiring.

Correct the encoder wiring.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

The servomotor did

not run with posi-

tion reference input.

Wirings of the servomotor U, V, and W are incorrect. Correct the servomotor wiring.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Normal movement,

but occurred with a

long distance refer-

ence input.

The SERVOPACK gain adjustment is improper.

Increase the speed loop gain (Pn100) and position

loop gain (Pn102).

The position reference pulse frequency is too high.

Adjust slowly the position reference pulse fre-

quency.

Apply the smoothing function.

Correct the electronic gear ratio.

Setting of the overflow level (Pn505) is incorrect. Set the parameter Pn505 to proper value.

The servomotor specifications do not meet the load

conditions such as torque and moment of inertia.

Reconsider and correct the load and servomotor

capacity.

A.F1

Power Line

Open Phase

(In the main

power supply

ON status, the

voltage stays low

for 1 second or

more at one of

the phases R, S,

and T.)

(Detected when

the main circuit

power supply

turns ON.)

Occurred when the

control power sup-

ply was turned ON.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Occurred when the

main circuit power

supply was turned

ON.

The three-phase power supply wiring is incorrect. Correct the power supply wiring.

The three-phase power supply is unbalanced. Balance the power supply by changing phases.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Occurred when the

servomotor was

running.

The contact in three-phase power supply wiring is

faulty.

Correct the power supply wiring.

Three-phase power supply is unbalanced. Balance the power supply.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Table 11.3 Alarm Display and Troubleshooting (Cont’d)

Alarm

Display

Alarm Name

Situation at Alarm

Occurrence

Cause Corrective Actions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...