Version 16.10 AF-6600 AF-5000 Series Install Manual 150

Fuel Flow Transducer Installation

The inlet and outlet ports in the fuel flow transducer

have ¼” NPT threads. Use only ¼” NPT hose or pipe

fittings to match. When assembling fittings into the inlet

and outlet ports DO NOT EXCEED a torque of 180 inch

lbs, or screw the fittings in more than 2 full turns past

hand tight WHICHEVER HAPPENS FIRST. AFS will

not be responsible for cracked castings caused by

failure to use ¼” NPT fittings, over-torqueing the fittings,

or assembling them beyond the specified depth. Use

only aircraft FUEL LUBE on the NPT fittings; NEVER

USE TEFLON TAPE or SILICON SEALER IN AN

AIRCRAFT FUEL SYSTEM.

A screen or filter should be installed upstream of the flow transducer to screen out debris which could affect

rotor movement or settle in the V-bearings.

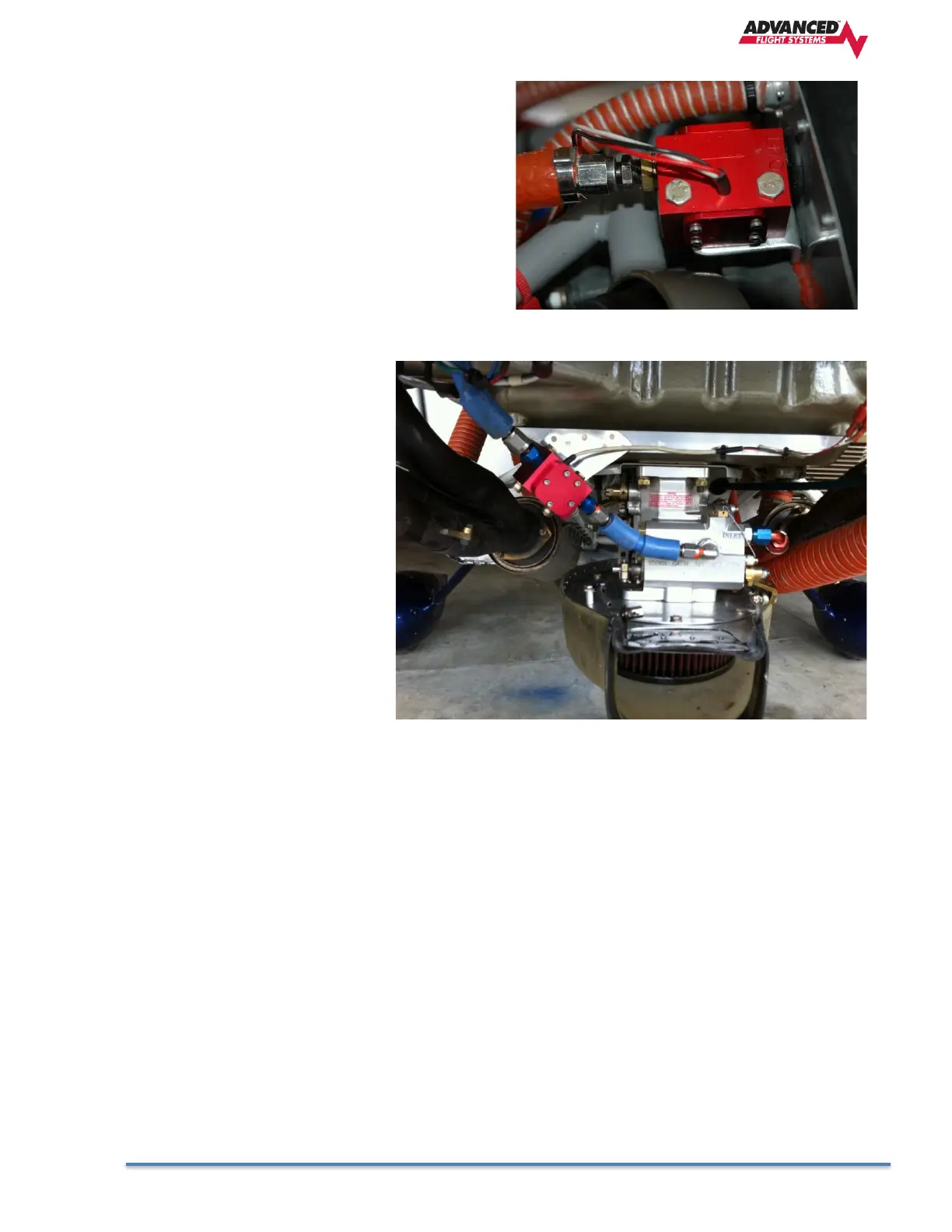

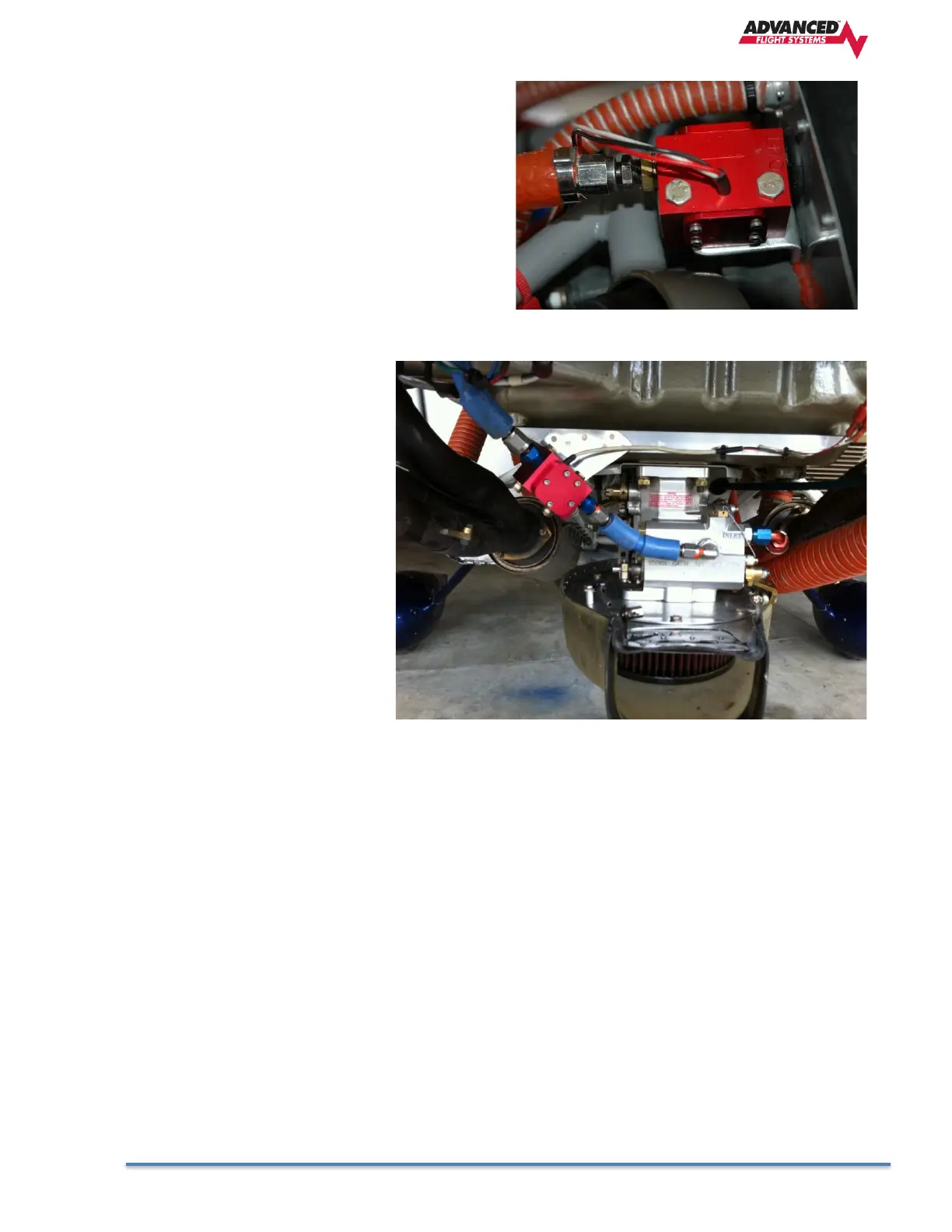

Mount the fuel flow transducer in a

position so the three wire leads are

pointed straight up. Use only smooth

radius curves in the fuel line and place

the transducer with 5” of straight line

before and after. The transducer wires

should be connected directly to the 37-

pin D-SUB using the cable provided.

The transducer should be mounted

according to the fuel metering device

manufacturer’s recommendations.

AFS has seen good results with the

following mounting:

1. The transducer in a stationary

location in-line between the

electric boost pump and the

engine driven pump.

2. The transducer in a stationary location in-line between the fuel injection servo and the distribution

block.

3. The transducer in a stationary location in-line between the Engine driven pump and the Carburetor.

NOTE: The Electronics International FT-60 (Red Cube) transducer is rated for .6 – 70+ GPH. AFS

recommends that the Electronics International FT-90 (Gold Cube) transducer be used for applications

requiring more than 35 GPH (350HP) or for gravity flow fuel systems without a fuel pump (Contact AFS to

exchange transducers).

CAUTION: NEVER CONNECT THE FUEL FLOW TRANSDUCER DIRECTLY TO THE ENGINE WITHOUT

COVERING WITH FIRE SLEEVE.

The Fuel Flow transducer wires should be connected from the harness to the transducer using the supplied

connectors.

Pin 15 Red +8V

Pin 14 Yellow Signal

Pin 13 Black Ground

Loading...

Loading...