Version 16.10 AF-6600 AF-5000 Series Install Manual 29

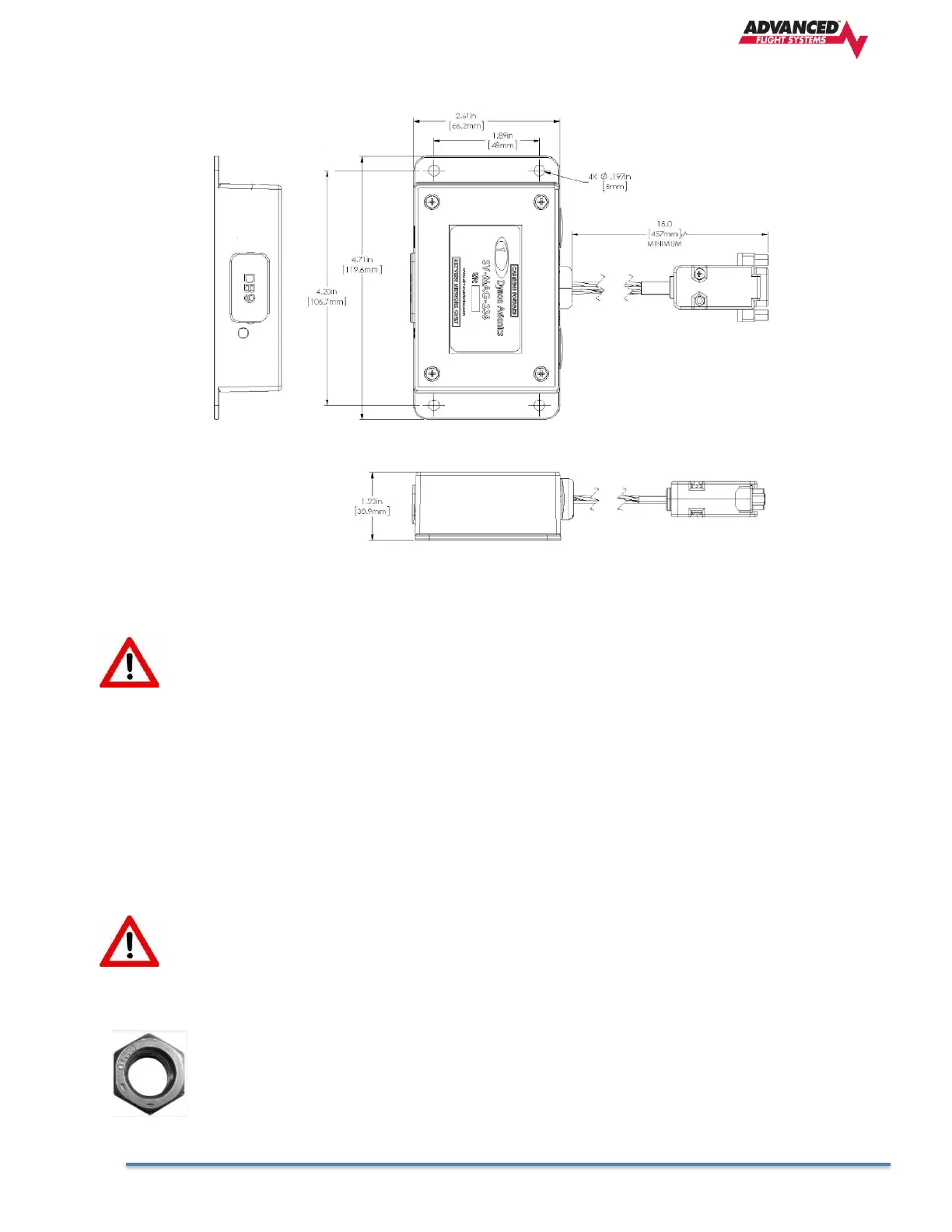

3.3 SV-MAG-236 Remote Magnetometer

The SV-MAG-236 Remote Magnetometer P/N: 72236 was developed for situations where the SV-ADAHRS-

200/201’s integrated magnetometer cannot be located in an area free of magnetic disturbances while

satisfying the other installation constraints (such as proximity to center of gravity) of the SV-ADAHRS-

200/201. The SV-MAG-236 is particularly recommended for steel-frame aircraft.

Proper installation of the Advanced-SV Magnetometer is critical. Performance is significantly linked

to a proper magnetometer installation. The installation location must meet all of the mechanical,

magnetic, orientation, and environmental requirements detailed below.

The location should be magnetically benign. Given that it may be difficult or impossible to avoid all sources of

magnetic interference, it is possible to characterize and compensate for small, static magnetic fields with

calibration. Calibration cannot, however, compensate for dynamic magnetic fields (e.g., AC currents, non-

constant DC currents, and non-stationary ferrous material such as electric turn coordinators and control

surfaces). Thus, you must avoid mounting the module close to sources of dynamic magnetic fields, avoid

wires that carry large amounts of current, and use non-magnetic fasteners for installation. AFS’s general rule

of thumb is that 1 to 2 feet between the module and sources of magnetic fields is generally good enough, but

2 or more feet is better.

Use of stainless steel mounting hardware is not recommended as it is not always non-magnetic.

If you use a magnet to test whether possible interfering materials are non-magnetic, do not actually

touch the magnet to the material you are testing, as this contact can cause the material you are

testing to become magnetized.

Move a handheld compass throughout the space surrounding your intended location to get a

rough idea of the suitability of the area. Note that this test should be done with major aircraft

systems operating (e.g., strobe lights and radios on) because some systems can cause

magnetic interference. If the compass needle deviates significantly from magnetic North or

cycles back and forth, the location is not ideal for ADAHRS installation.

Loading...

Loading...