38 1100 Series FD Reference Manual

2 First Steps with the Fluorescence Detector

Step 1: Check the LC system for impurities

A critical issue in trace level fluorescence detection is to have an LC system

free of fluorescent contamination. Most contaminants derive from impure

solvents. Taking a fluorescence scan is a convenient way to check the quality

of the solvent in a few minutes. This can be done, for example, by filling the

FLD cuvette directly with the solvent for an offline measurement even before

the start of a chromatographic run. The result can be displayed as an

isofluorescence plot or a three-dimensional plot. Different colors reflect

different intensities.

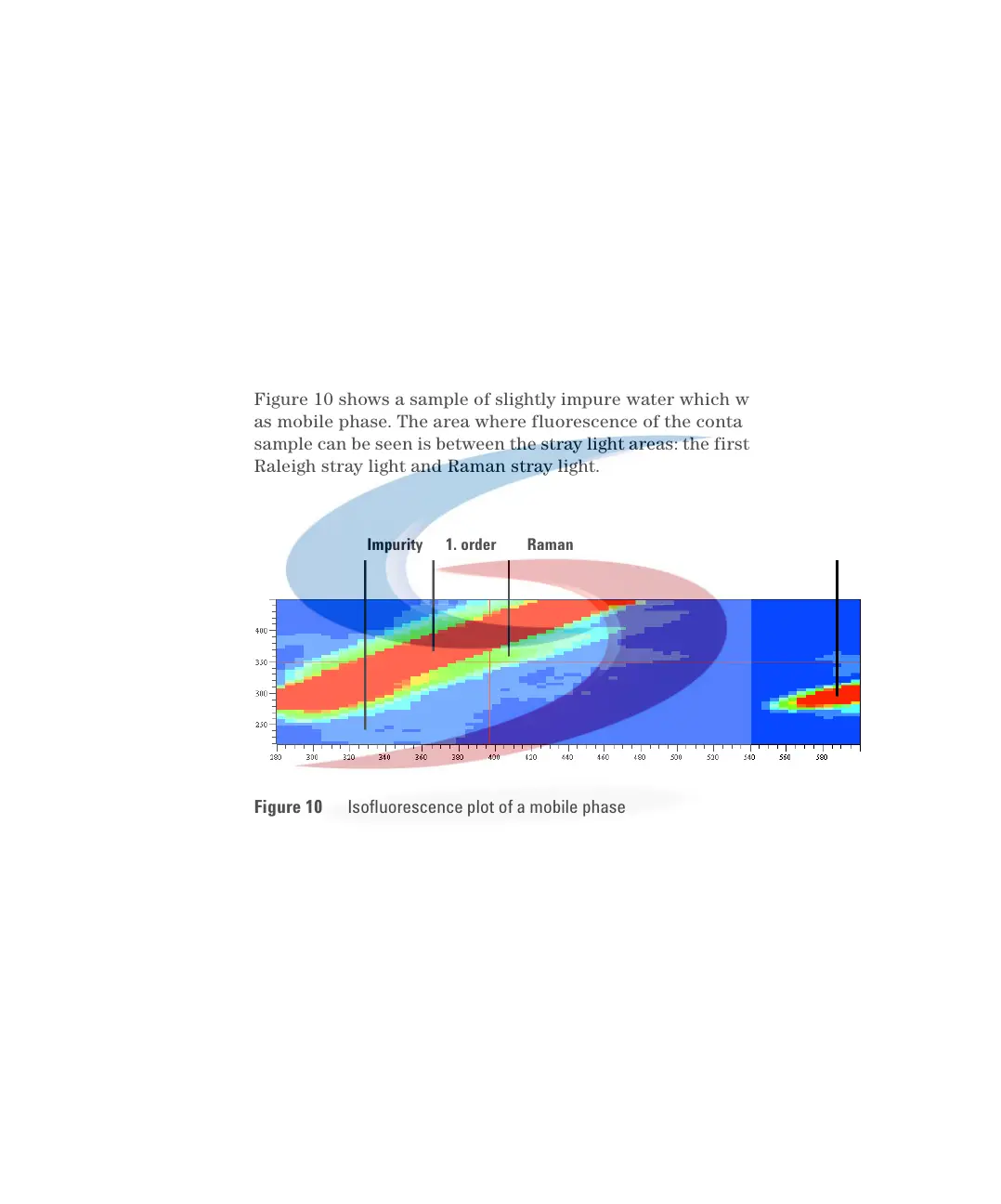

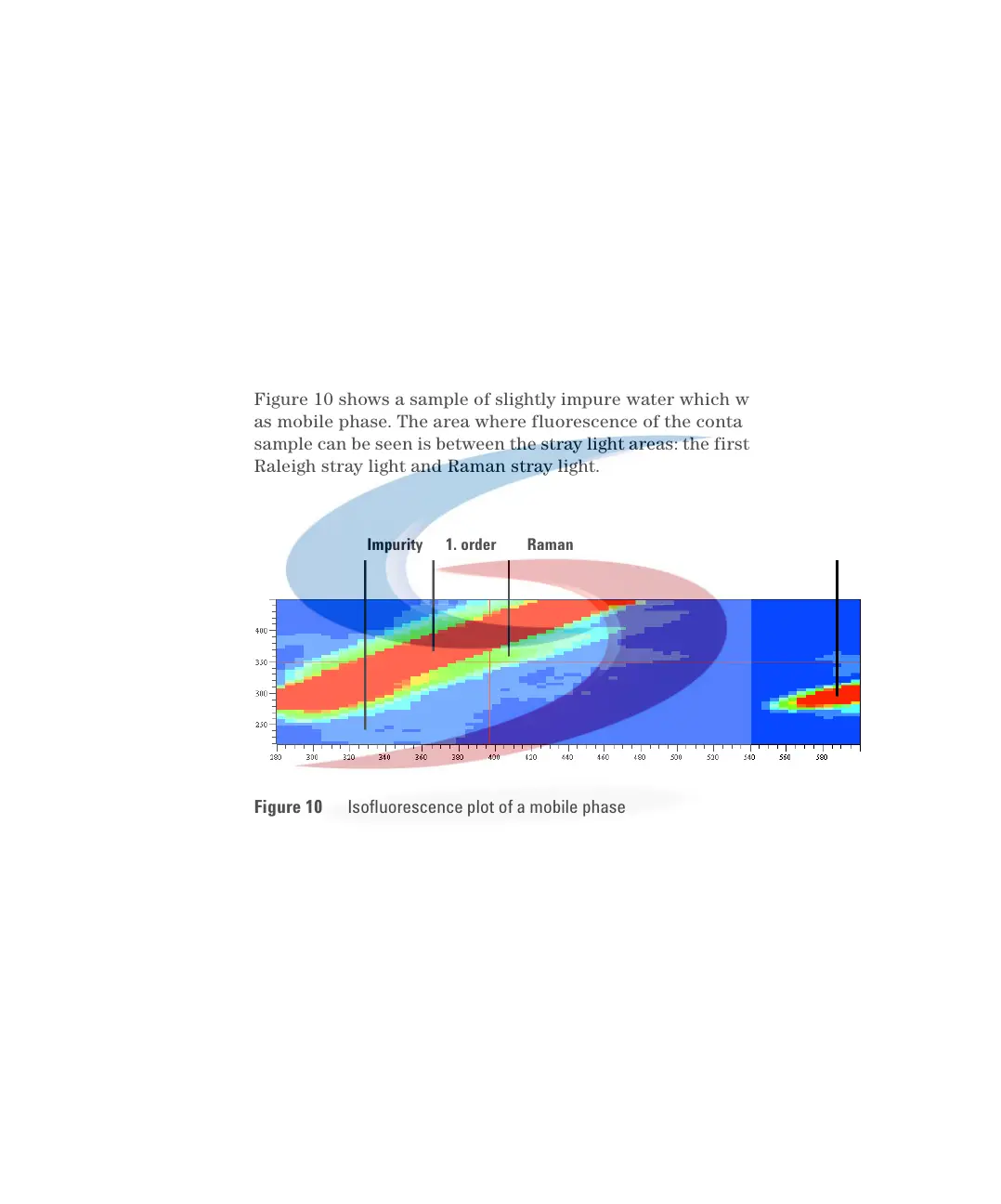

Figure 10 shows a sample of slightly impure water which was planned for use

as mobile phase. The area where fluorescence of the contaminated water

sample can be seen is between the stray light areas: the first- and second-order

Raleigh stray light and Raman stray light.

Since "excitation" and "emission" wavelength are the same for Raleigh stray

light, the area of first-order Raleigh stray light is visible in the left upper area

of the diagram. The Raman bands of water are seen below the first-order

Raleigh stray light. Since the cut-off filter cuts off light below 280 nm, the

second-order Raleigh stray light starts above 560 nm.

Figure 10 Isofluorescence plot of a mobile phase

A pure water

sample was put

into the flow cell.

Spectra were

recorded at 5 nm

step sizes.

Impurity 1. order Raman 2. order

Loading...

Loading...