Sheet #673u – Definition, characteristics and measurement principles

Version 1.04a User guide ATEQ 6th series Page 1/7

DEFINITION, CHARACTERISTICS AND MEASUREMENT

PRINCIPLES

1. DEFINITION OF THE ATEQ 6

TH

SERIES

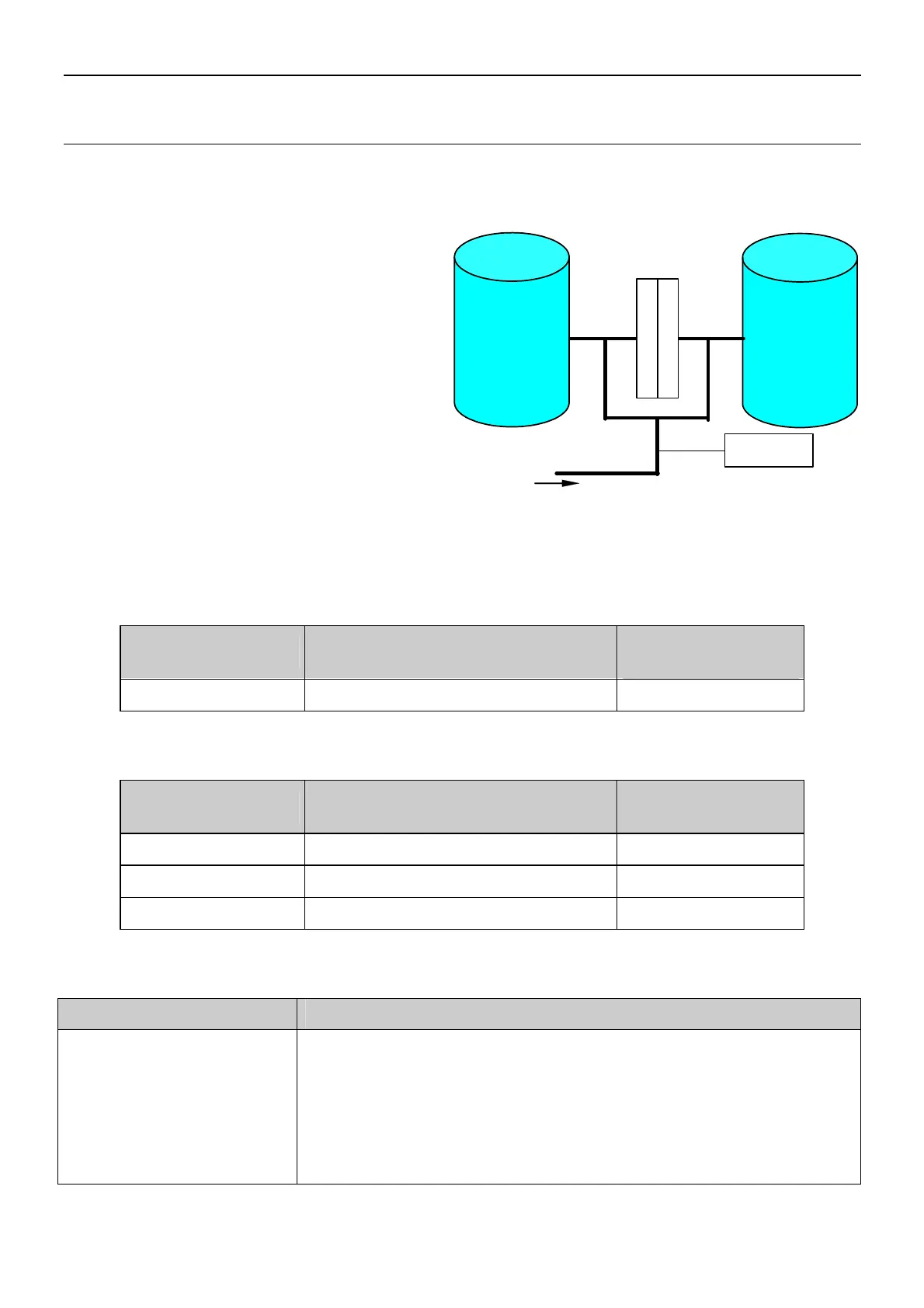

The ATEQ 6

th

series is a state of the art

touch color screen compact air/air leak

detectors designed to test the air-

tightness of parts on production lines. It is

specially adapted for automatic and

semi-automatic workbenches. The

method used is based on the

measurement of a small variation or drop

in differential pressure between the test

and reference parts, when both are filled

to an identical pressure.

CAPTEUR PIEZO

PRESSION DE

TEST AIR

CAPTEUR

DIFFERENTIEL

PIECE DE

REFERENCE

PIECE A

TESTER

2. MEASUREMENT CHARACTERISTICS

2.1. PRESSURE DROP MEASUREMENT

RANGE ACCURACY

maximum

RESOLUTION

0 – 500 Pa 2.5% of the pressure +/- 1 Pa 0.1 Pa

2.2. TEST PRESSURE MEASUREMENT

RANGE ACCURACY

maximum

RESOLUTION

F.S. = 200 mbar +/- (1.5% of the pressure + 0.2 hPa) 0.1 % FS

0.2 < F.S. 5 bar +/- (1.5% of the pressure + 7.5 hPa) 0.1 % FS

5 < F.S. 10 bar +/- (1.5% of the pressure + 15 hPa) 0.1 % FS

2.3. MECHANICAL PRESSURE REGULATION

Mechanical regulation Electronic regulation

80 kPa to - 2 kPa.

0,5 kPa to 14 kPa.

5 kPa to 50 kPa.

20 kPa to 400 kPa.

50 kPa to 900 kPa.

- 80 kPa to - 2 kPa.

1 kPa to 20 kPa.

2 kPa to 50 kPa.

10 kPa to 100 kPa.

20 kPa to 200 kPa.

50 kPa to 500 kPa.

100 kPa to 1000 kPa

- 100 kPa to + 100 kPa.

- 100 kPa to + 400 kPa.

- 100 kPa to + 1000 kPa.

For other pressure ranges please contact ATEQ.

Loading...

Loading...