Sheet #673u – Definition, characteristics and measurement principles

Version 1.04a User guide ATEQ 6th series Page 3/7

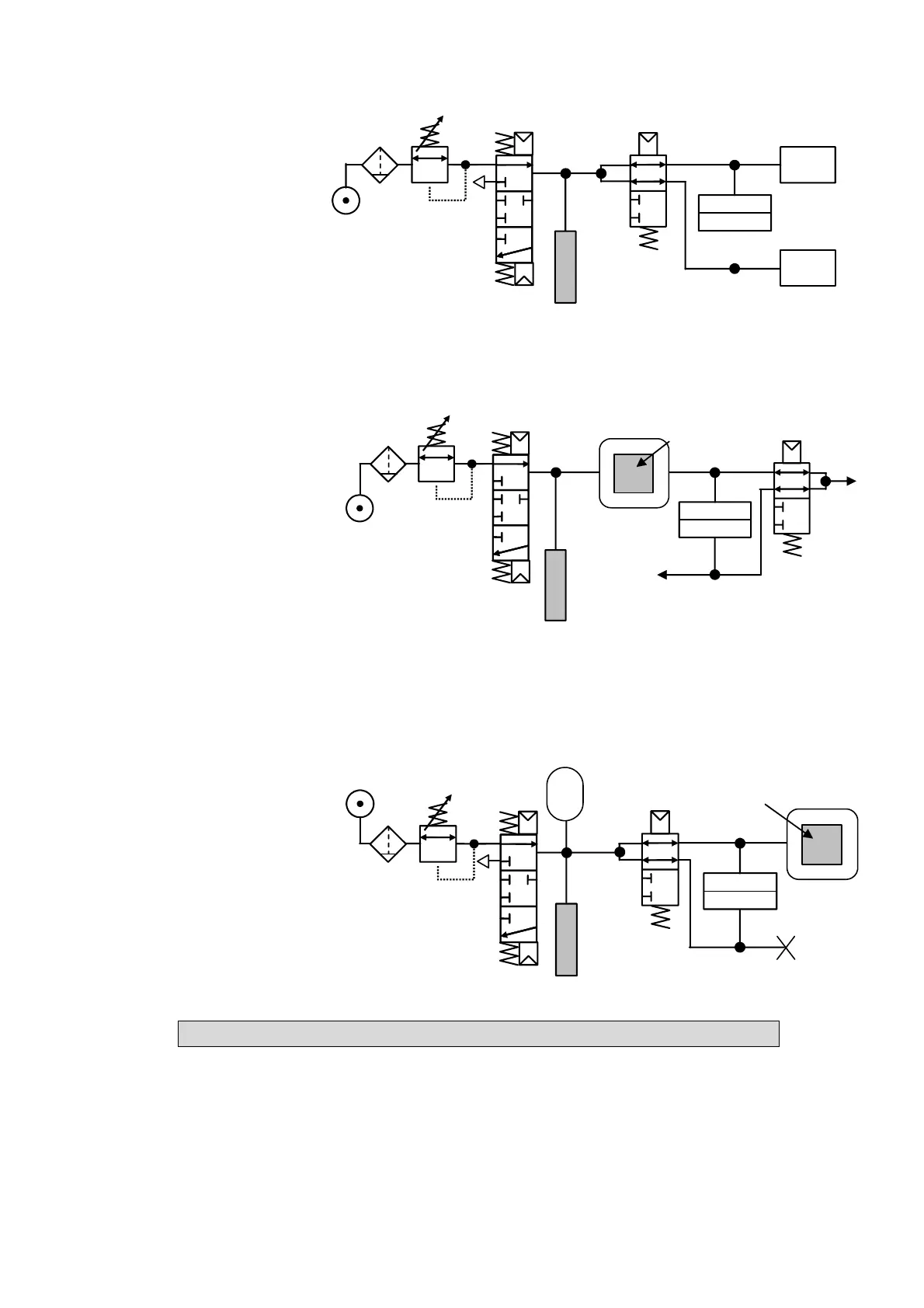

3.1.1. 1) Direct or pressure drop measurement

After filling the test and

reference parts to the required

pressure level, the instrument

measures the differential

pressure between the two

volumes which are separated

by the equalization valve.

Reference part

Test part

Electronic

ressure sensor

At the end of a cycle, the instrument empties the components via the dump valve.

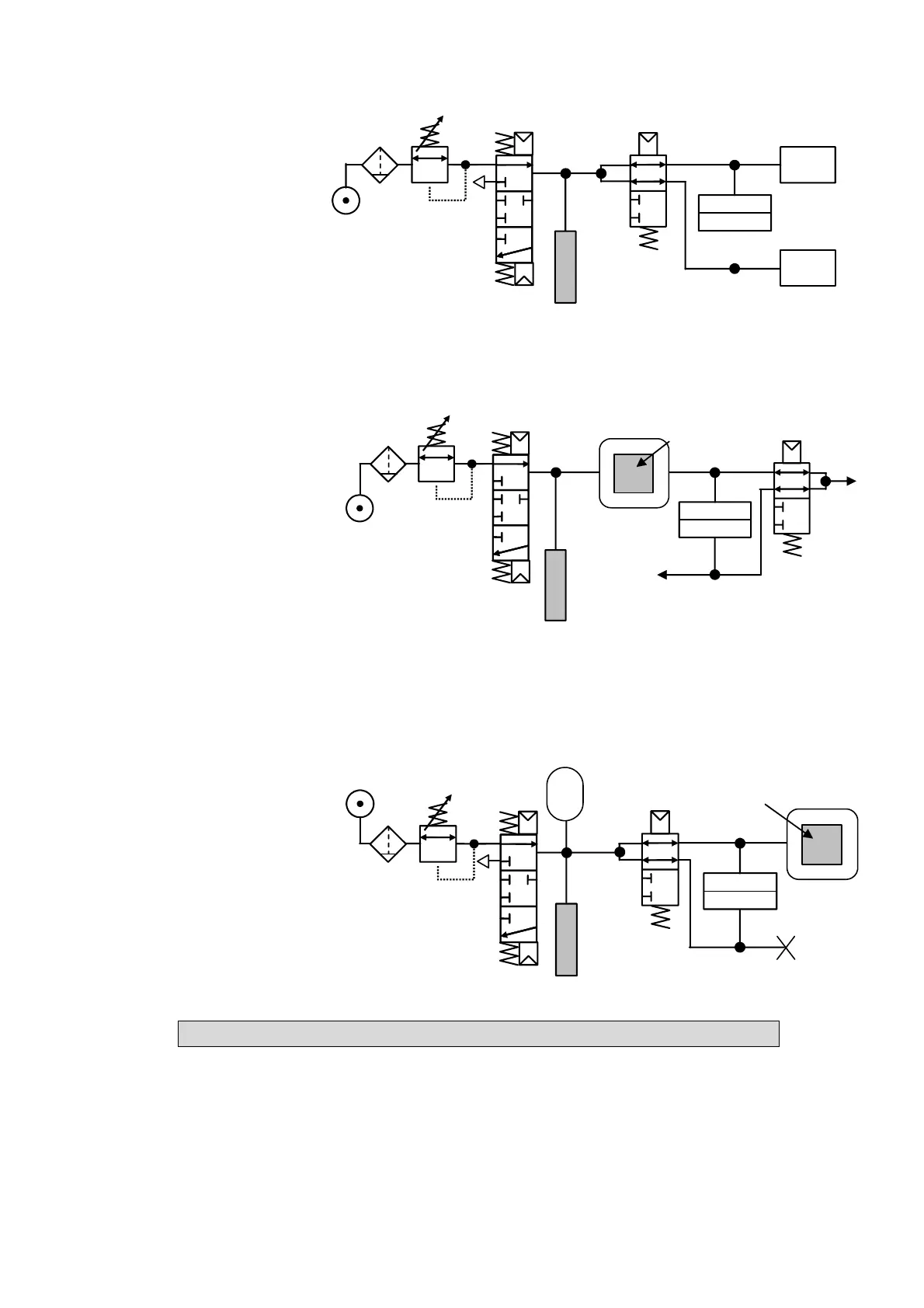

3.1.1. 2) Indirect Pressure rise measurement

The test part is placed in a

sealed bell and the instrument

is pneumatically connected to

the bell. The part is externally

pressurized (with up to 20 MPa

or 200 bar) and the bell is

lightly pressurized. In the event

of a part leakage, the pressure

in the bell will rise.

P atm

Test part

Electronic

pressure sensor

P atm

Reclaimable

bell

Transducer

This method allows certain parts to be tested at high pressure levels whilst avoiding the

associated constraints. The instrument only tests and measures the pressure in the bell. In the

event of a large leak, electronic monitoring of the pressure in the bell will switch the instrument

to safety. A security valve must be installed on the bell.

3.1.1. 3) Sealed component measurement

This test is intended for sealed

parts which cannot be filled at

the test pressure. They are put

into the bell. The bell is

pressurized by dumping air

from an intermediary volume.

The difference in the amount of

air from a good to bad part can

be measured. The pressure in

the bell is controlled according

to the formula:

Test part

Electronic

pressure switch

Plugged ref.

output

Bell

Transducer

Internal volume

P1 V1 = P2 (V1 + V2) with V1 bell volume V2 internal volume

The first and the third measurements may be carried out in comparison with a reference,

without reference or in central zero.

Three kinds of sealed components are available, see sheet #613.

Loading...

Loading...