Sheet #673u – Definition, characteristics and measurement principles

Version 1.04a User guide ATEQ 6th series Page 5/7

3.1.3. Direct pressure measurement

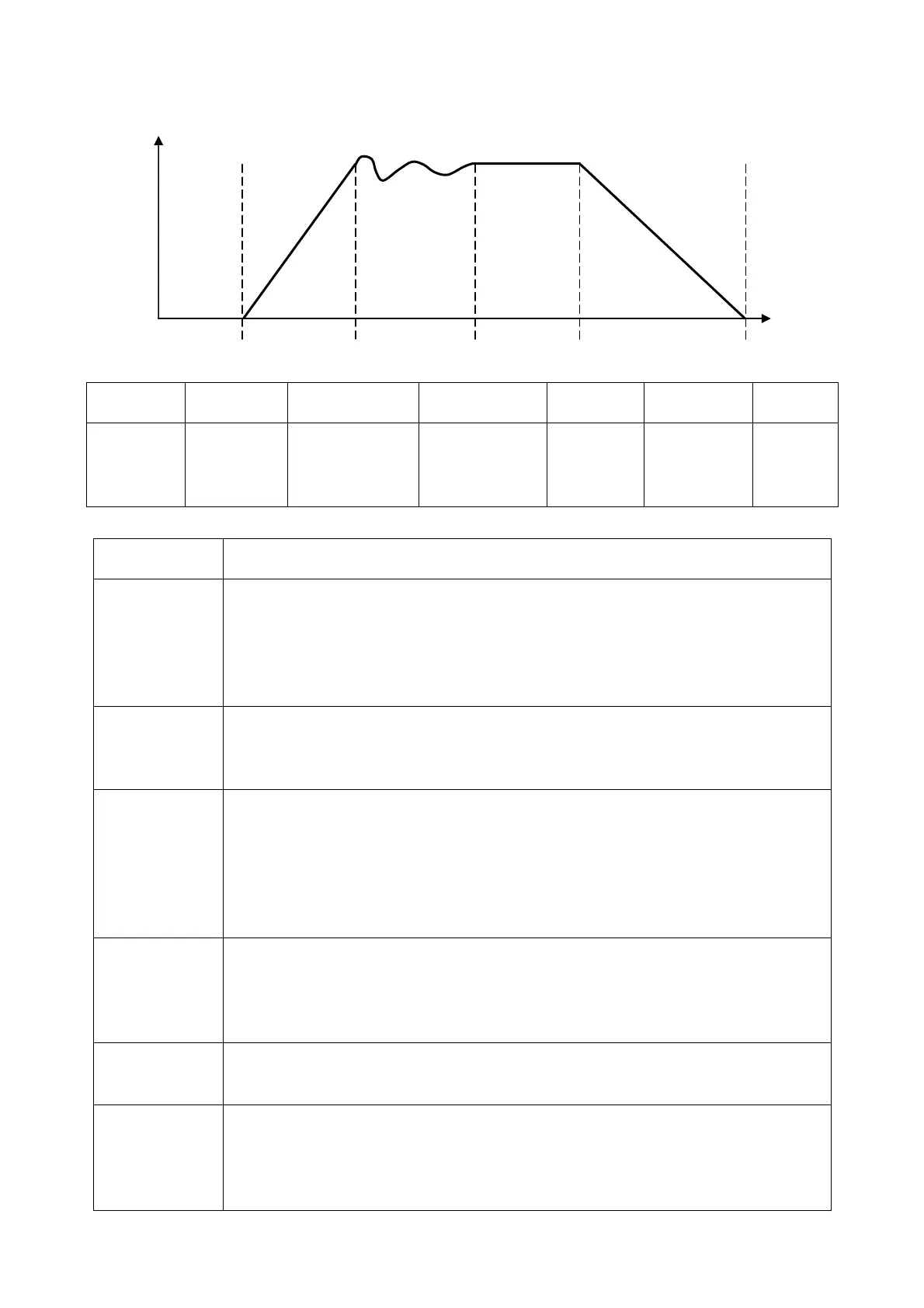

FILL STABILISATION TEST DUMP WAIT

The measurement cycle consists of 5 phases:

1 2 3 4 5

Start

Coupling

time

(wait)

Fill time

Stabilization

time

Test

time

Dump

time

Cycle

end

Start

Cycle start

Coupling

time (wait)

The time during which the sealing connections are made to the test

parts before they are filled. The instrument may be fitted with the

optional automatic connector. This valve is controlled for the duration of

the cycle to enable the checking of the installation of the expandable

joint connectors.

Fill time

Pressurization of the test and reference parts. At the end of the fill time,

the ATEQ instrument checks the test pressure against the pressure

thresholds. If this is not correct, it will signal a test pressure fault.

Stabilization

time

The test and reference parts are completely cut off from the air supply,

but are pressurized to the test pressure. Pressure and temperature will

then stabilize between the two parts which communicate and act

similarly. If the test pressure is incorrect (a large leak on one of the

volumes) the test pressure will drop rapidly, the instrument will not

move on to the test mode and will indicate a fault.

The test time

The test and reference parts are isolated from each other and the leak

sensor measures the difference in pressure between them. The signal

is electronically assessed and displayed; the part is then diagnosed as

good or bad.

The dump

time

Return of the parts to atmospheric pressure.

End of

Cycle

Once the dump has been carried out, the instrument sends the end of

cycle signal and the automatic connector valve (optional) is

deactivated. This valve can control one or more expandable connectors

from the beginning to the end of the cycle.

Loading...

Loading...