Sheet #673u – Definition, characteristics and measurement principles

Version 1.04a User guide ATEQ 6th series Page 7/7

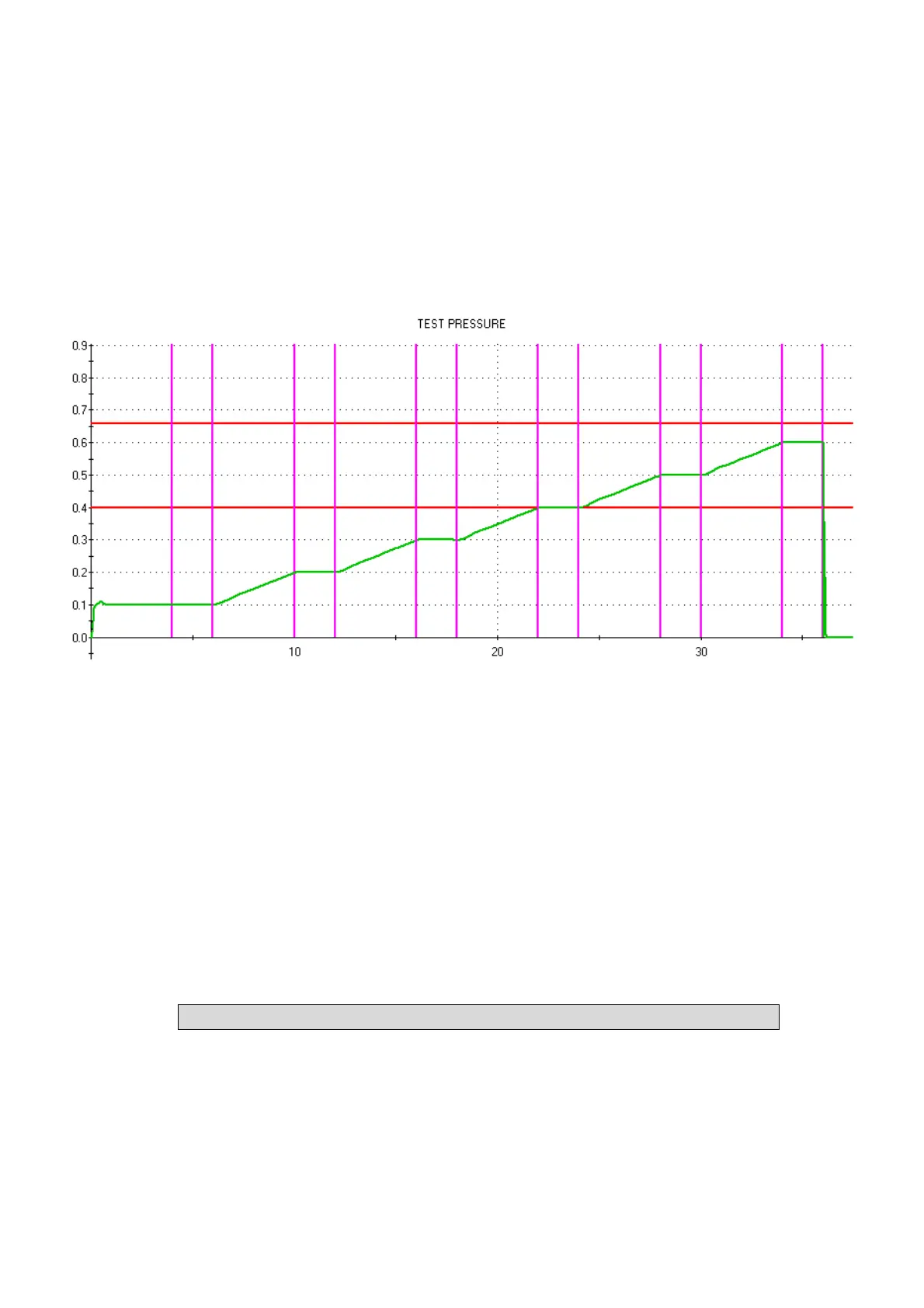

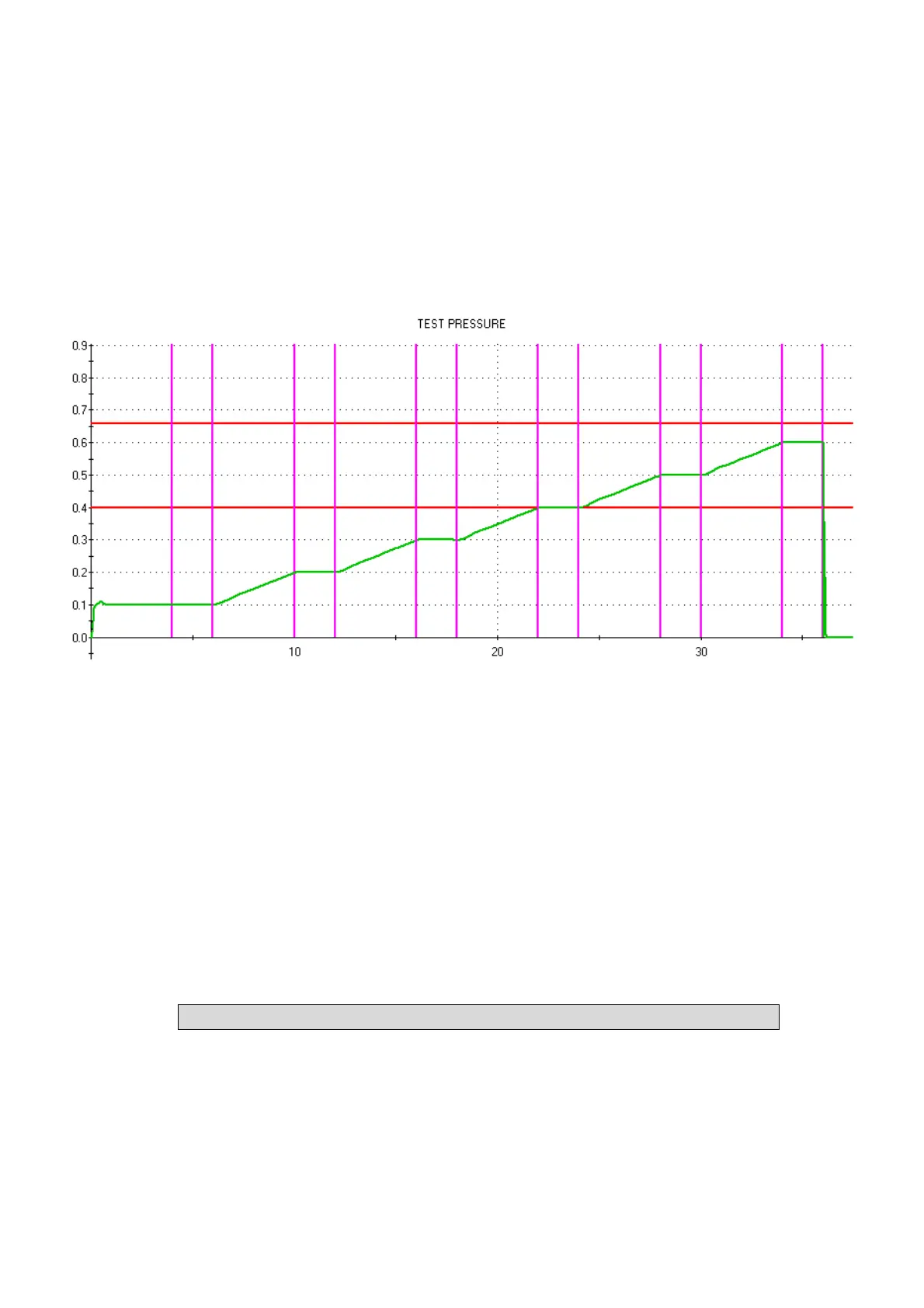

3.5. BURST TEST (OPTION)

The burst test allows following up the pressure which the part will burst.

To see the burst pressure, a pressure rise is generate with steps, once the pressure is dropping

quickly, this pressure is recorded and the device will check if it is between the programmed

thresholds.

The burst test runs currently only with volumes with a few tens cm

3

.

Example :

The above burst test is configured with:

¾ Ramp with 6 steps.

¾ Rise time: 4 seconds.

¾ Step Time: 2 seconds.

3.6. V

OLUME TEST (OPTION)

The volume test allows measuring the volume of a part.

An internal known volume (connected to the valve pressurization output) is filled to a known

pressure. This volume is dumped in the test part, the difference of pressure consequent gives

the test part volume with the formula:

P1 V1 = P2 (V1 + V2) with V1 internal volume V2 test part volume

The internal known volume must be configured in the program parameters.

Loading...

Loading...