Sheet #607u – ATR 0 – 1 – 2 – 3 function

Version 1.04a User guide ATEQ 6th series Page 1/6

ATR 0 - 1 - 2 - 3 FUNCTIONS

1. PRINCIPLE

Problem:

Is the pressure drop occurring during the test time due

to a leak or a transient effect?

The test environment is not always ideal for the

measurement of pressure drops. There are several

momentary events (ex: temperature or volume

variations...) that can influence the measurement.

They are called transient effects.

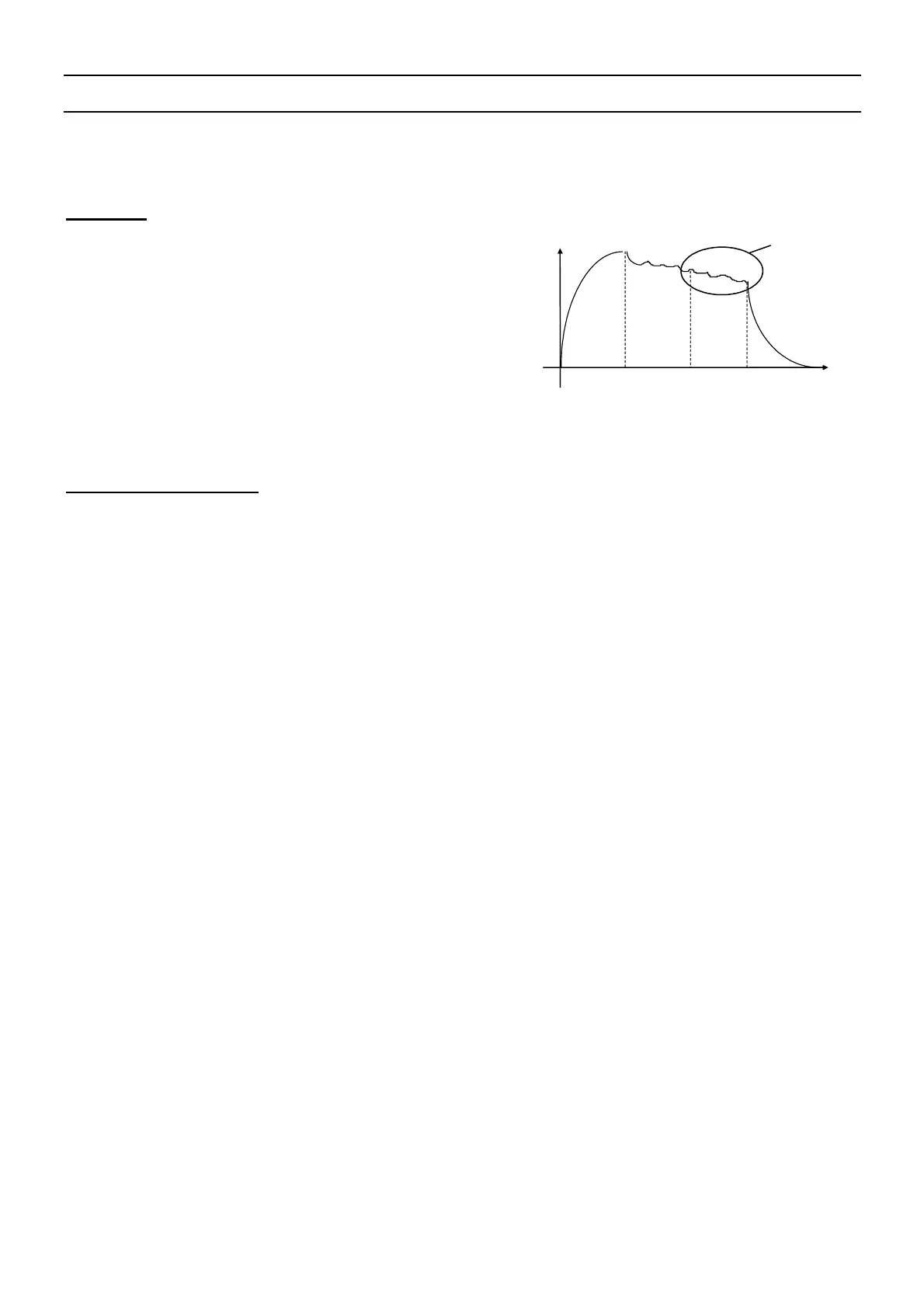

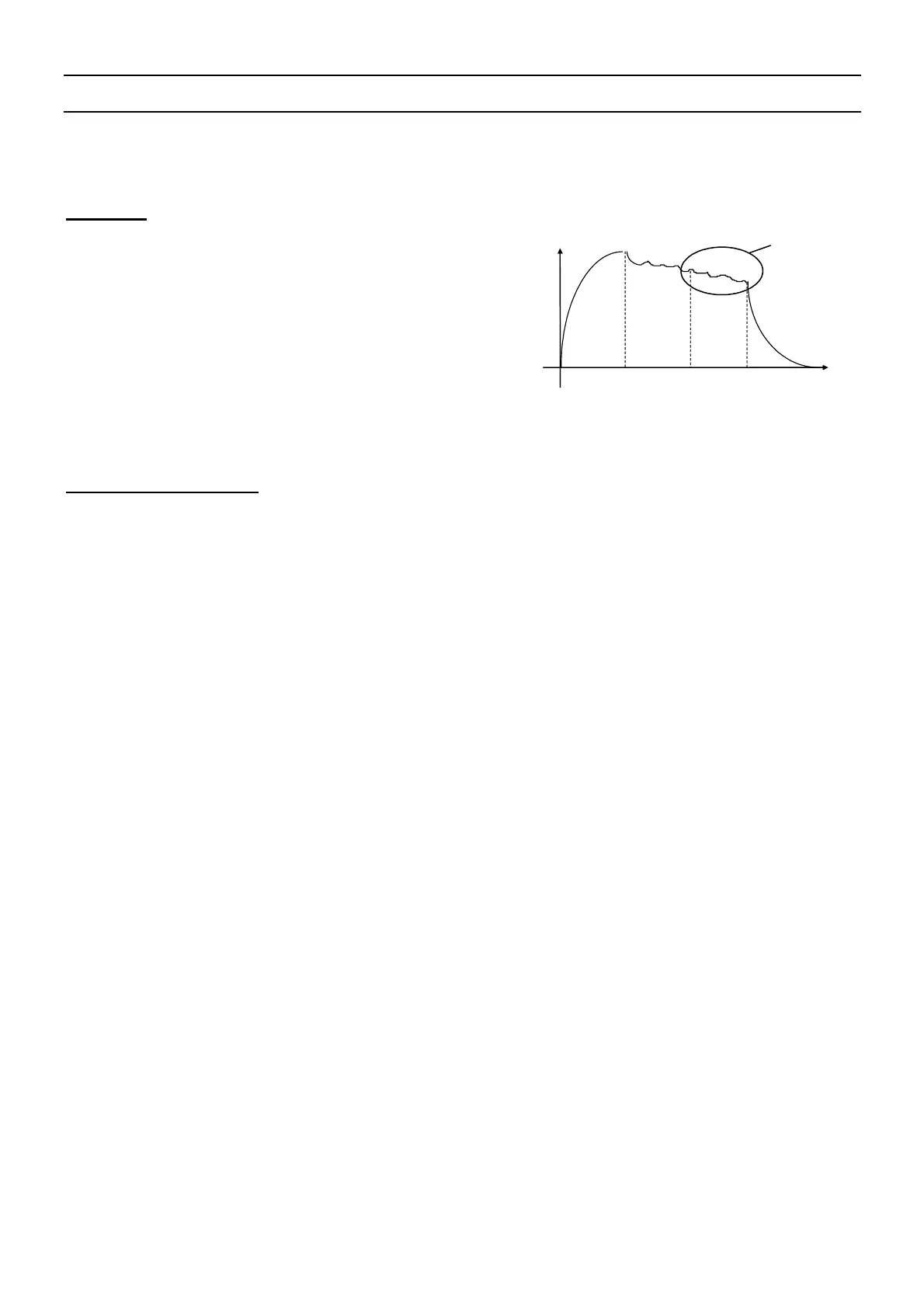

Fill Stab. Test Dum

Time

Press

Pressure

drop

To avoid any interference, it is possible to increase the stabilization time to obtain the ideal

measurement conditions during the test phase. However, increasing the stabilization time for

each test may not be acceptable for optimal production speed.

Operational principle:

The principle consists of measuring the pressure variations caused by transient phenomena through

the use of a learning cycle and then removing these variations from the final test result for a part.

Three ATR (Attenuated Transient Reduction) functions are available: ATR0, ATR1, ATR2 and

ATR3. ATR1 and ATR2 are different because of their learning cycles.

1.1. ATR0

The initial value of the transient is known. Parameters must be set manually.

The ATR may only be used on parts that have identical behaviors during the test, in other

words, parts that have an identical transient.

Associated parameters to be set are:

¾Start (Initial value of the transient),

¾Transient

(actual, non modifiable value of the transient),

¾Per

centage drift (Percent of the reject level, the measurements used for transcient

calculation are less than this value).

¾Drift (Drift tolerance on acquisition of the transient, as a % of the Reject level).

The “start” value is saved and subtracted from the final result of the tests.

Loading...

Loading...