Page 4–50

DURApulse GS4 AC Drive User Manual – 1st Ed, Rev A - 10/20/2017

Chapter 4: AC Drive Parameters

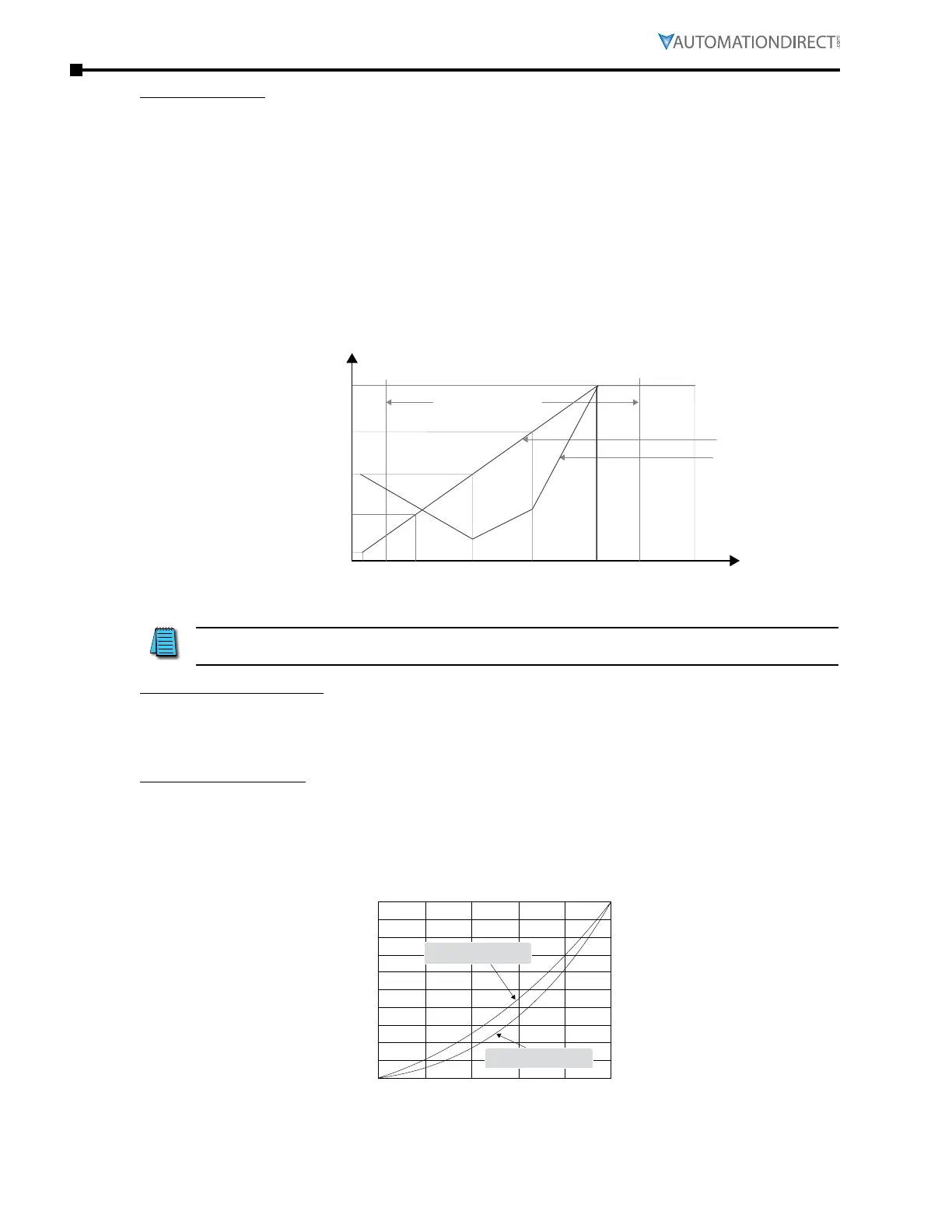

Setting 3: Custom

The setting of a custom V/Hz curve usually follows the load characteristics of a motor. If the

workload exceeds a motor’s capacity, pay attention to its heat dissipation, dynamic balance, and

bearing lubrication.

Custom V/Hz curves are used when “General Purpose,” “High Starting Torque,” or “Fan and Pump”

curves do not deliver the voltage required for the application.

If the voltage setting at low frequency is set to too high a value, it can cause motor insulation or

coil damage through motor overheating, cause a motor stall prevention event, and/or contribute

to over current protection faults. Care must be given to the determination of this parameter’s

value to best protect the motor and provide the best application experience.

The V/Hz curve of Motor 1 is shown below. The V/Hz Curve of Motor 2 will be similar, using

comparable parameters for Motor 2 as shown in ().

P2.06

(P2.14)

P2.04

(P2.12)

Mid Freq1

P0.02

(P0.13)

P0.04

P2.08

(P2.16)

P2.19

Start Freq

P6.26 Output Frequency Lower limit P6.25 Output Frequency Upper Limit

Motor Maximum Output Voltage

P0.00 (P0.11)

Frequency output

ranges limitation

Regular V/Hz Curv

Special V/Hz Curve

Middle Output Voltage 1

P2.05 (P2.13)

Middle Output Voltage 2

P2.07 (P0.15)

Minimum Output Voltage

P2.09 (P2.17)

Frequency

(Px.xx) = parameters for motor #2

NOTE: P2.04~P2.09 and P2.12~17 are used only when the V/Hz parameter (P2.00) is set to

03.

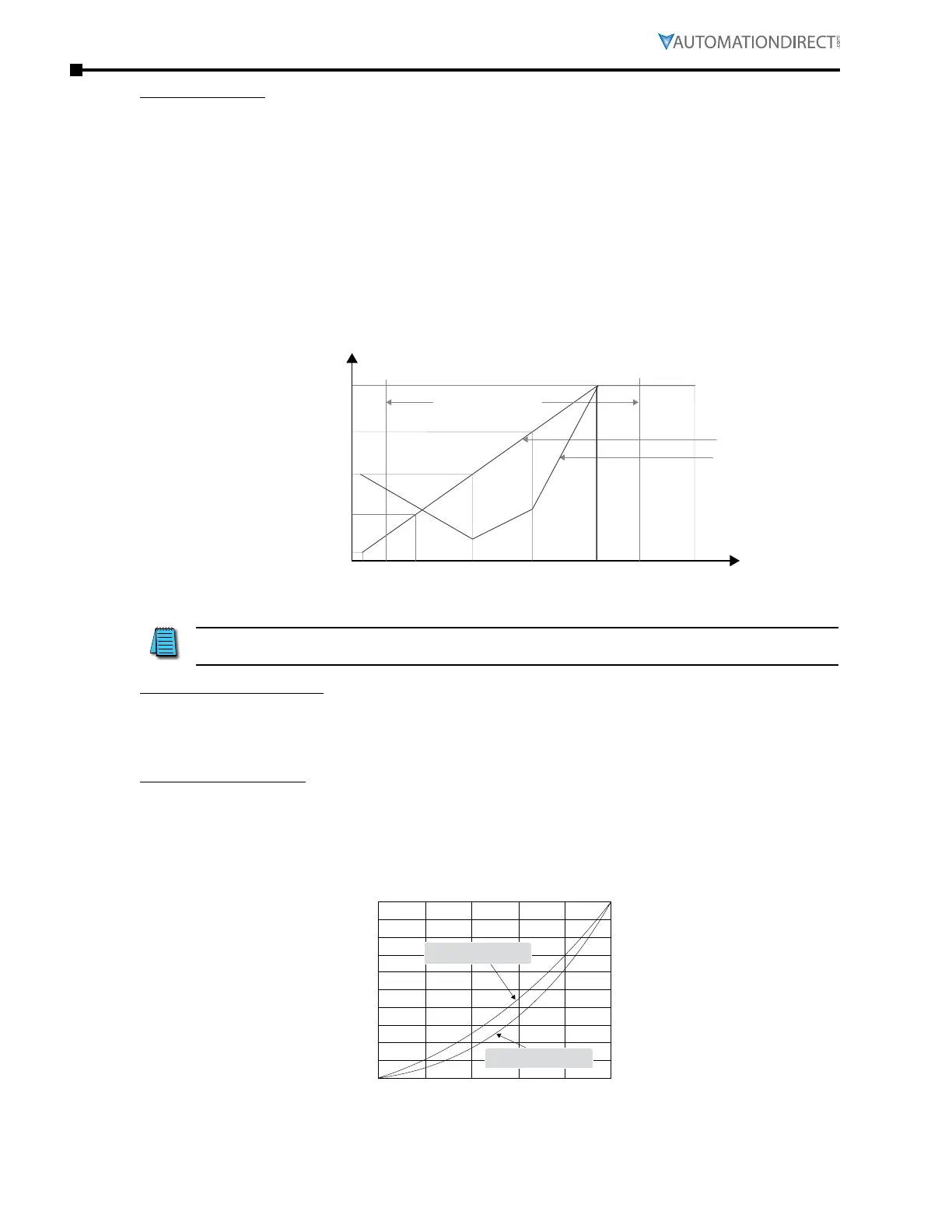

Setting 4: 1.5 Power Curve

•

V

out

= [(P0�00-P2�09) x ([(F

x

-P2�08)/(P0�00-P2�09)]

3

)

0�5

] + P2�09

•

Where: V

out

is GS4 drive output voltage; F

x

is GS4 drive output frequency

•

Refer to “Energy Saving Power Curves for Fans & Pumps” V/Hz curve below Setting 05�

Setting 5: Square Curve

•

V

out

= [(P0�00-P2�09) x ([(F

x

-P2�08)/(P0�00-P2�09)]

2

)] + P2�09

•

Where: V

out

is GS4 drive output voltage; F

x

is GS4 drive output frequency

•

Refer to “Energy Saving Power Curves for Fans & Pumps” V/Hz curve below�

energy Saving Power curveS For FanS & PuMPS (P2.00 SeTTingS 04 & 05)

0

100

90

80

70

60

50

40

30

20

10

1.5 power curve

Square curve

P0.02 Hertz %

Loading...

Loading...