Chapter 4: AC Drive Parameters

Page 4–125

DURApulse GS4 AC Drive User Manual – 1st Ed, Rev A - 10/20/2017

grouP P6.xx details – Protection ParaMeters

Type Hex Addr Dec Addr

P6.00 Electronic Thermal Overload Relay (Motor 1)

♦R/W 0600 41537

Range/Units (Format: 16-bit binary) Default

0: Constant Torque

1: Variable Torque

2: Inactive

1

The Electronic Thermal Relay Selection is used to prevent a self-cooled motor from overheating

under low speed. This setting limits the drive’s output power.

This parameter determines the drive’s motor overload protection characteristic. The Variable

Torque setting (01) allows less motor current at lower speeds than does the Constant Torque

setting (00).

Related parameter: P6.01

Setting 0: Constant Torque (Recommended for inverter/vector duty motors)

Use this setting when using the GS4 drive

with motors designed specifically for AC drive

outputs, and for running at low speeds with

high currents. Motor currents will be 100%

throughout the speed range, and can be up to

150% for one minute.

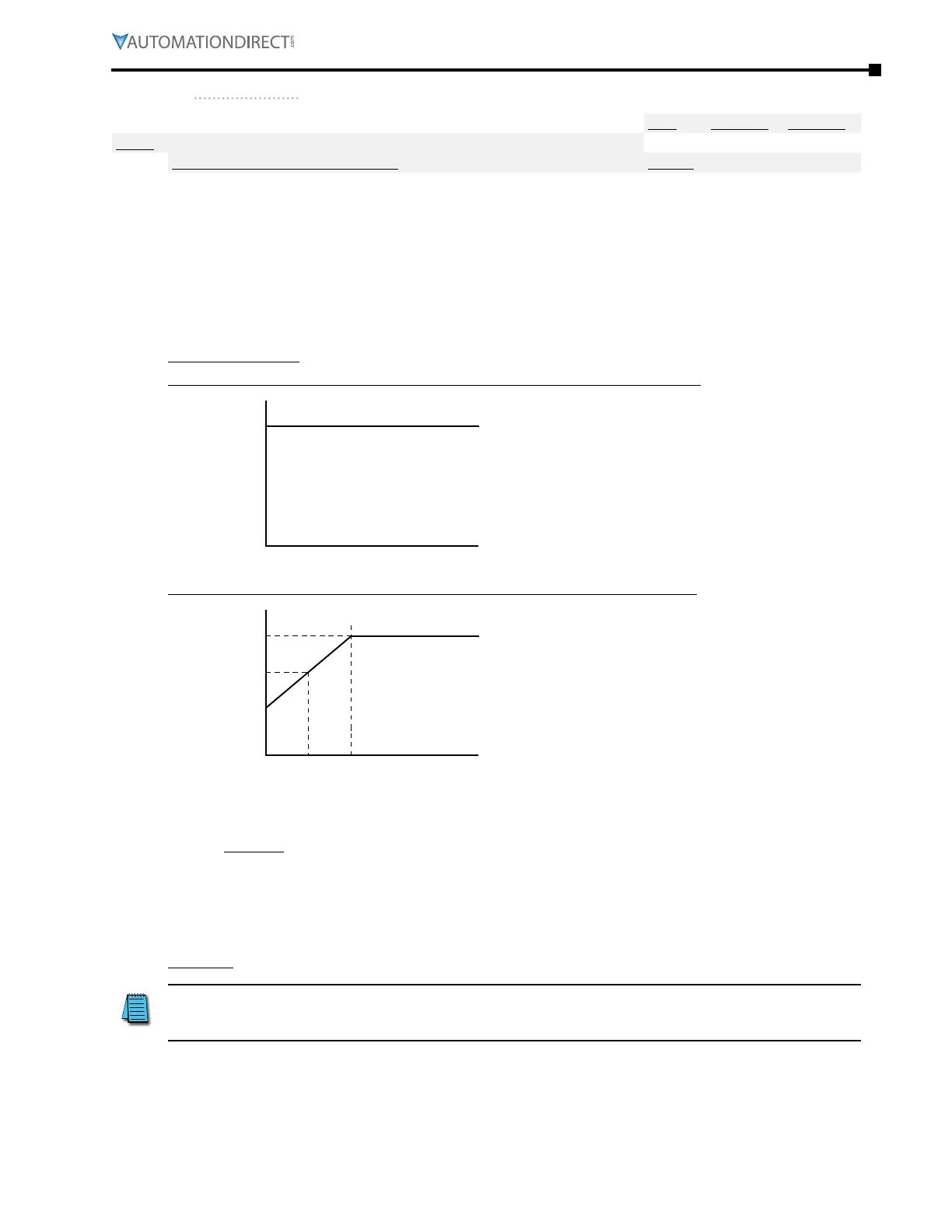

Setting 1: Variable Torque (Recommended for fan-cooled standard motors)

40%

70%

Use this setting when using the GS4 drive with

motors which are NOT designed specifically

for AC drive outputs. Motors with shaft

mounted fans offer poor cooling at low speeds,

therefore the output can be derated at lower

output frequencies. This derated current is for

protecting the motor at lower speeds.

The output current is derated as follows:

•

I

output

(%) = [ ƒ

output

(Hz) x 1�2 %/Hz ] + 40%

Example: If the rated motor current is 10A, and the output frequency is 25Hz, the derating

will be 70%, and the overload will be 10.5A (150%) for one minute:

•

I

output

(%) = [ (25Hz) (1�2 %/Hz) ] + 40% = 70%

•

10A x 70% = 7A

•

7A x 150% = 10�5A

Setting 2: Inactive

NOTE: P6.00/P6.02 (Electronic Overload Relay) must be set independently, yet in conjunction

with P6.33 (Drive Derating Method), and P6.34 (VT/CT Duty Selection).

When P6.34 is set, it can change P2.10 (PWM Carrier Frequency); refer to P2.10.

Loading...

Loading...