Operation 59

Package Detection System (PDS)

The Package Detection System monitors packages as they pass the Burford

®

Model

2000/2100 Servo Tyer and stops the bagger if a twist-tie is not applied. The system

automatically resets after the next accepted package.

The PDS operates by monitoring the package sensor to determine when a package is in

the operating area of the Servo-Tyer. Once a package is present, the system waits for

the Servo-Tyer to actuate its counter contacts. If the Servo-Tyer has not counted the

package as good before a preset time period has expired, the PDS will open the bagger

safety circuit, stopping the bagger.

This feature can be disabled with DIP SWITCH 7 on the CPU board see pg. 88.

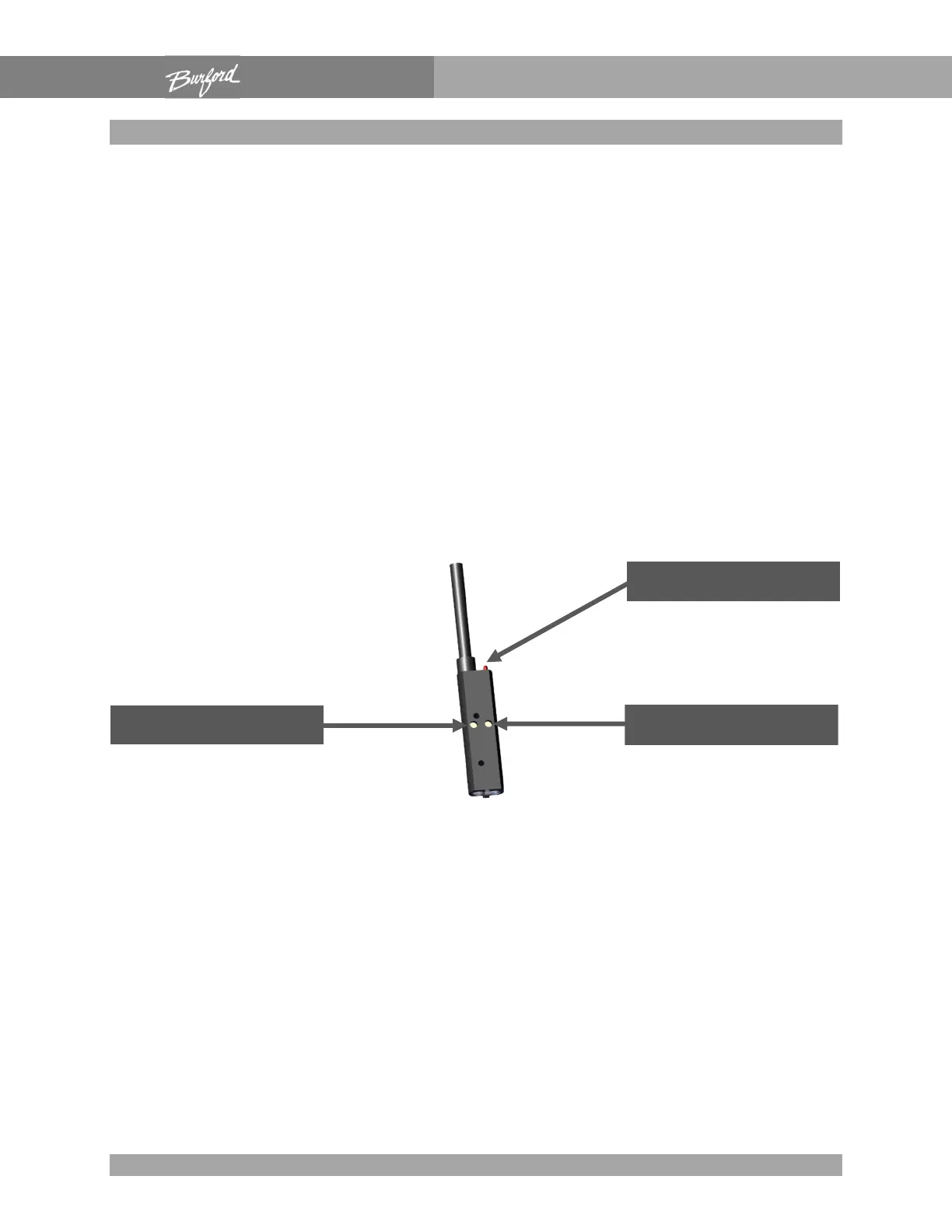

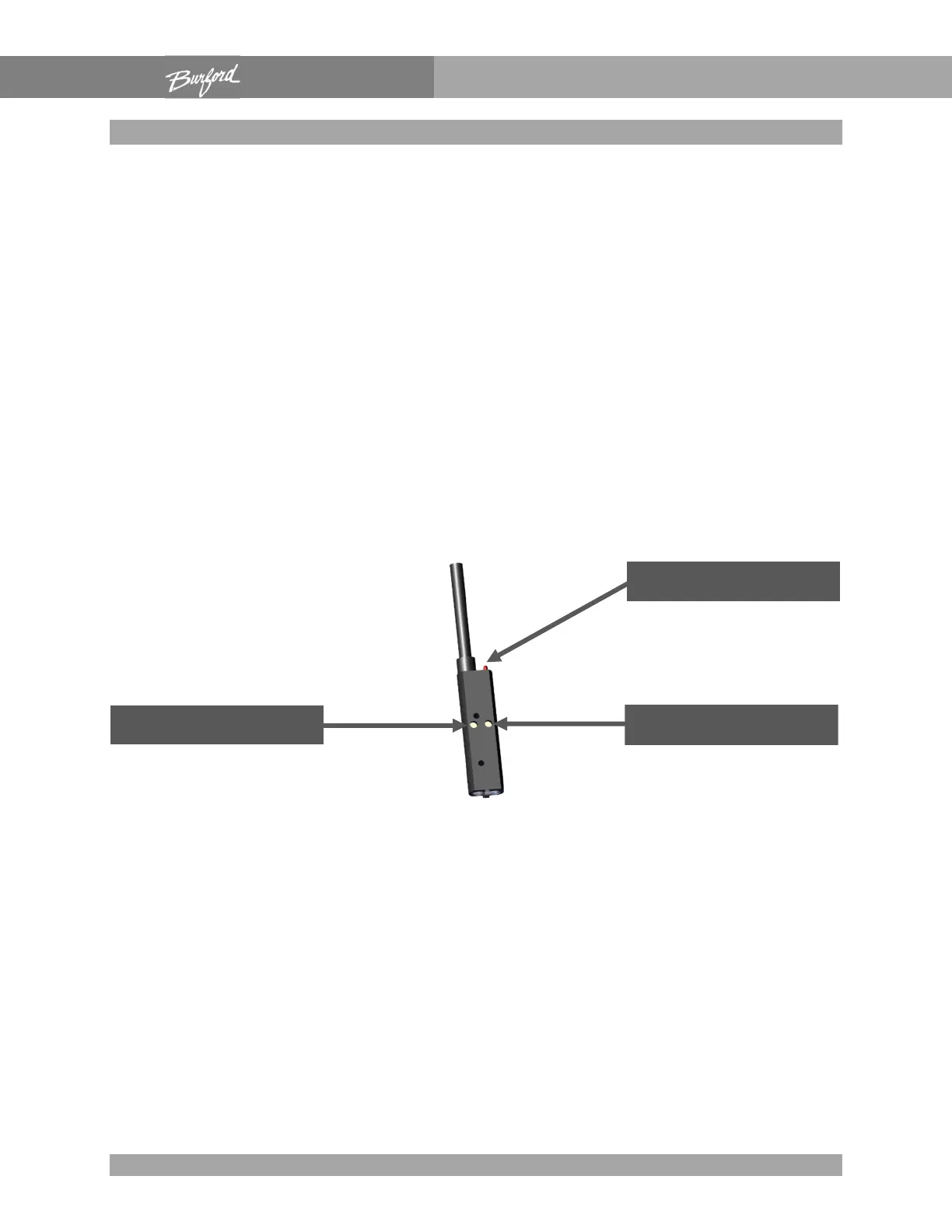

The Package Sensor is an advanced retro-reflective photo-proximity type. The sensor is

factory preset to accommodate a large range of bag types and conveyor surfaces.

However, for optimal operation, it is likely that some user adjustment may be required.

Verify that the sensor does not detect the conveyor flights and does detect both the

longest and shortest package that is run on the line.

If adjustments to the package sensor are required, turn the sensor gain and light / dark

detect potentiometers until satisfactory operation is obtained. The sensor bracket may

also be bent to extend or decrease the detection distance across the conveyor. Please

note that bending the bracket will often require the sensitivity of the package sensor to be

readjusted for optimal operation. See above figure for the location of the adjustment

potentiometers and operate LED.

Sensor Gain

Operate LED

Light / Dark

Loading...

Loading...