74

Chapter 5

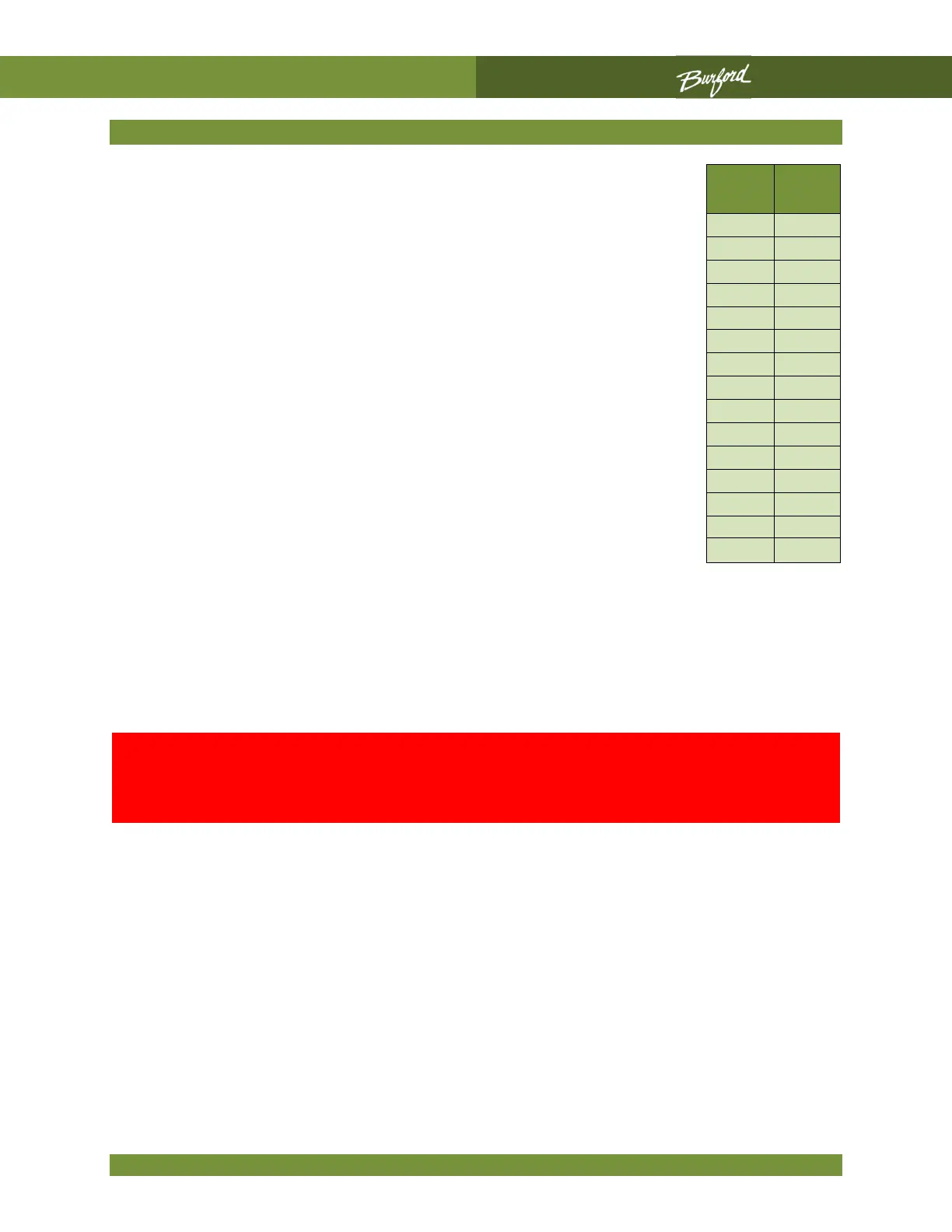

Gathering Belts Speed Adjustment

In normal operation, the push wheel switch on the Control Panel

enables the operator to adjust the speed of the gathering belts. The belt

speed ranges from a setting of zero to fifteen. In normal operation, each

speed setting is approximately 15 percent faster than the previous

setting (see table below for approximate values). A proper speed

setting should pull the product 1”-2” ahead of the flight and finish tying

as the flight catches up with the product (see pg.56 on how to adjust

the belt speed).

In most installations, the belts will not normally run when the conveyor

is stopped. For testing, you may make the belts run with the conveyor

stopped by turning the selector switch on the operator panel to the “ON”

position. Be sure to return the switch to the “AUTO” position after

testing. To properly set the speed of the gathering belts, you must be

running product at normal speed. The speed of the belts should be

adjusted so that the end of the bag is pulled slightly forward from the

flights. As soon as the tyer completes its tie of the package, the

conveyor flight should be just catching up with the package. The flight

then carries the tied package away from the tyer.

The belts should not be run any faster than necessary to ensure that the tie is completed

just before the flight pushes the tied package out of the tyer. If the belts are running too

fast, a bag may be pulled into the tying position before the previous package has been

removed by its flight. This can cause two packages to be tied together or excess wear on

the belts.

BCD

Setting

EST.

Belt

1 18

2 22

3 27

4 33

5 40

6 48

7 58

8 70

9 85

A 103

B 125

C 151

D 182

E 221

F 267

If the belts are running too slowly, the package will tend to drag

back against its flight as it is being tied. In addition, it will appear as

if the tyer is not keeping up with the needed

production rate.

Loading...

Loading...