52

Installation

14.4. Connecting the process controller Type 8793

→ First connect the process controller as described in chapter “14.2. Connection of the positioner Type 8792”.

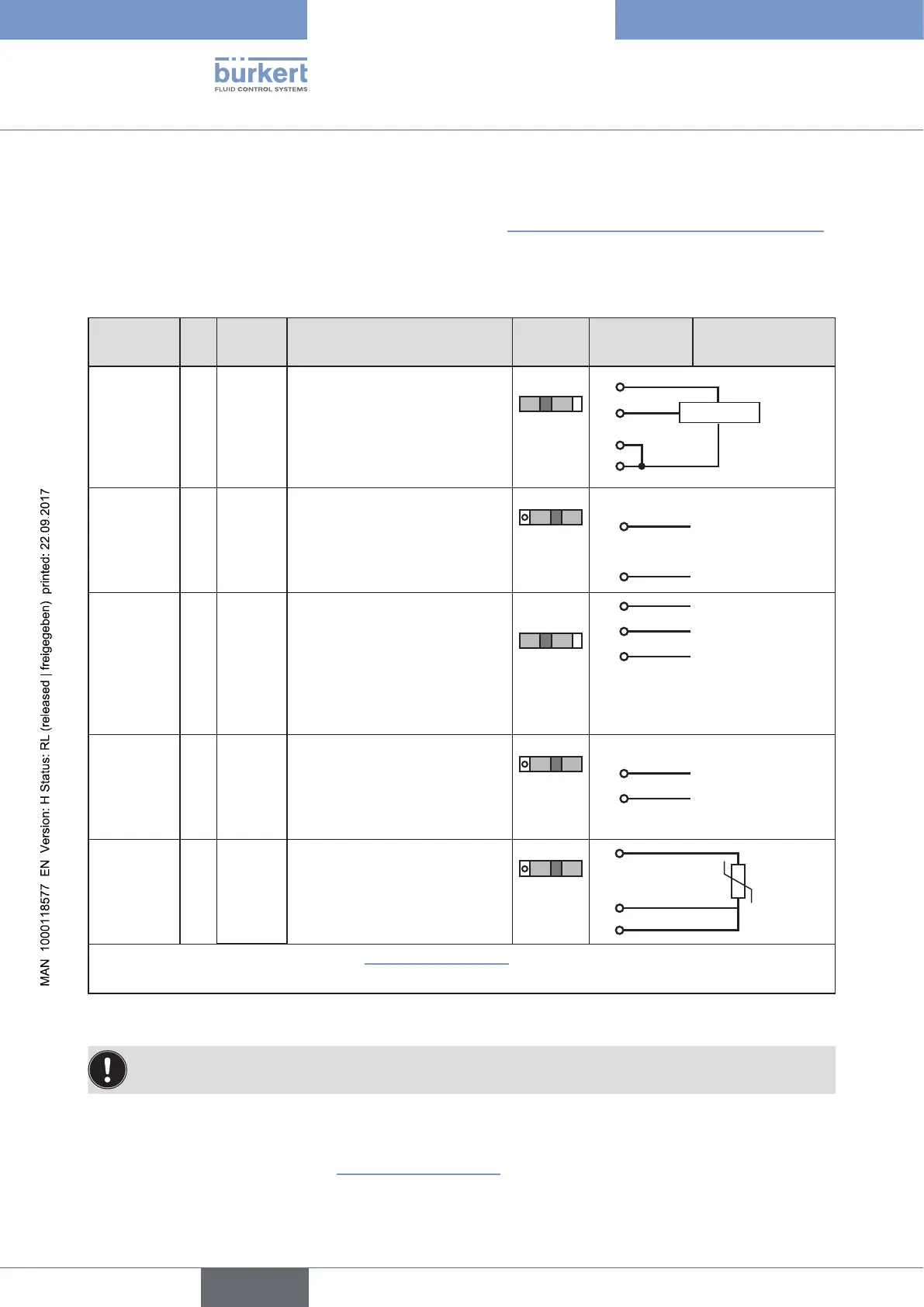

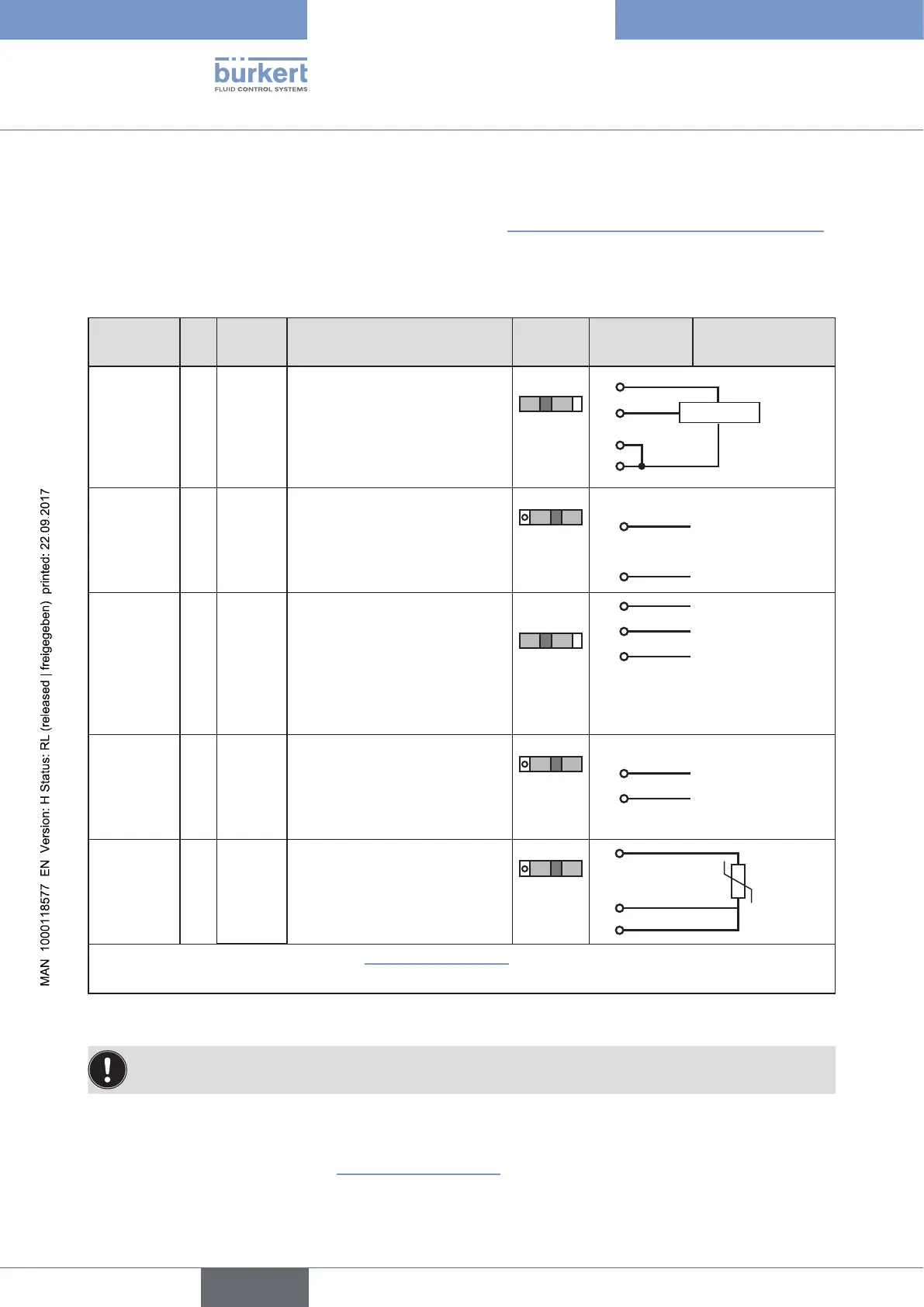

14.4.1. X5 - M8, 4-pole circular connector,

plug assignments of the process actual value input

Input type* Pin

Wire

colour**

Configuration

DIP

switches

On the

device side

External circuit

4 – 20 mA-

internally

supplied

1 brown +24 V transmitter supply

Switch

on left

1

2

3

4

Transmitter

GND

2 white Output from transmitter

3 blue GND (identical with GND

operating voltage)

4 black Bridge to GND (Pin 3)

4 – 20 mA-

externally

supplied

1 brown not used

Switch

on right

2 white Process actual + 2

4 - 20 mA

3 blue not used

4 black Process actual – 4

GND 4 - 20 mA

Frequency-

internally

supplied

1 brown +24 V sensor supply

Switch

on left

1

+24 V

2 white Clock input + 2 Clock +

3 blue Clock input – (GND) 3 Clock – / GND

(identical with GND

operating voltage)

4 black not used

Frequency-

externally

supplied

1 brown not used

Switch

on right

2 white Clock input + 2

Clock +

3 blue Clock input – 3 Clock –

4 black not used

Pt 100

(see infor-

mation

below)

1 brown not used

Switch

on right

2

3

4

Pt 100

2 white Process actual 1 (power supply)

3 blue Process actual 3 (GND)

4 black Process actual 2 (compensation)

* Can be adjusted via software (see chapter “21. Start-up sequence”).

** The indicated colors refer to the connection cable available as an accessory (918718).

Table 16: Pin assignment; X5 - M8, 4-pole circular connector - process actual value input

Connect the Pt 100 sensor via 3 cables for cable compensation reasons. It is essential to bridge terminal

3 and terminal 4 on the sensor.

When the operating voltage is applied, the process controller is operating.

→ Now make the required basic settings and actuate the automatic adjustment of the process controller. The

procedure is described in chapter “21. Start-up sequence”.

Loading...

Loading...