138

Salt build up, or thick salt layer at the bottom or on the inside can block the movement of the needle in

the wash head (or the movement of the wash head around the needle)

The through hole of the needle in the vertical carriage should be free of salt.

Salt around the needle can damage the needle and can influence the sampling process, sampling quality

or amount of sample

The wash head position relative to the needle and to the SR is not correct

The wash head comes down too far, and if lifted, leaves no room for the SR door to turn

The vertical rod holding the wash head is not inserted correctly, or was not pushed up to the maximum,

and the wash head is sitting in a low position

20.3.3 Shear Valve (SV) Related Errors

20.3.3.1 SV Error At The First Startup

the SV cannot turn:

o Make sure that the pull tab has been removed

o Check free movement by hand (rotate the shear valve)

The SV is stuck:

o Try to open the Shear Valve

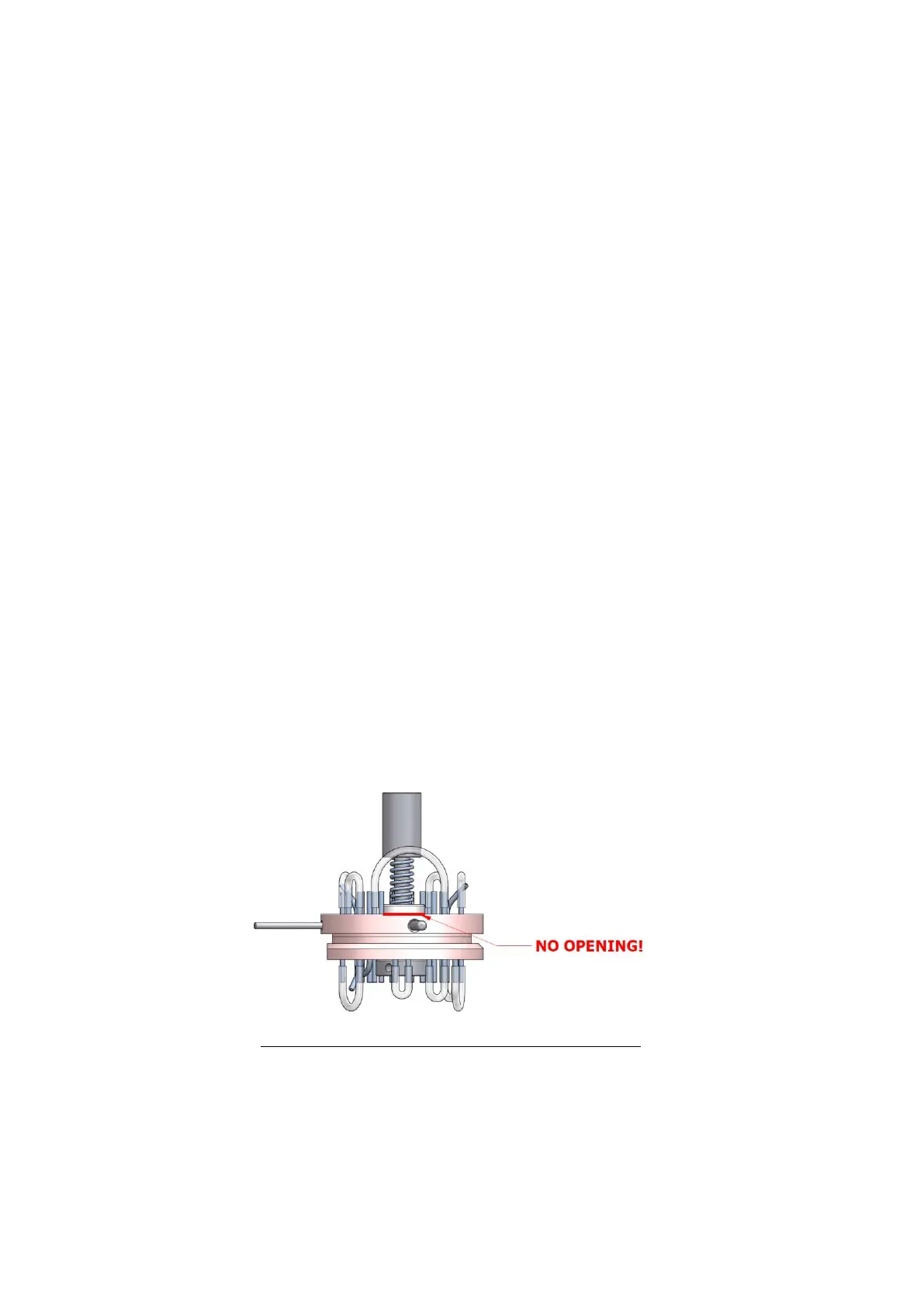

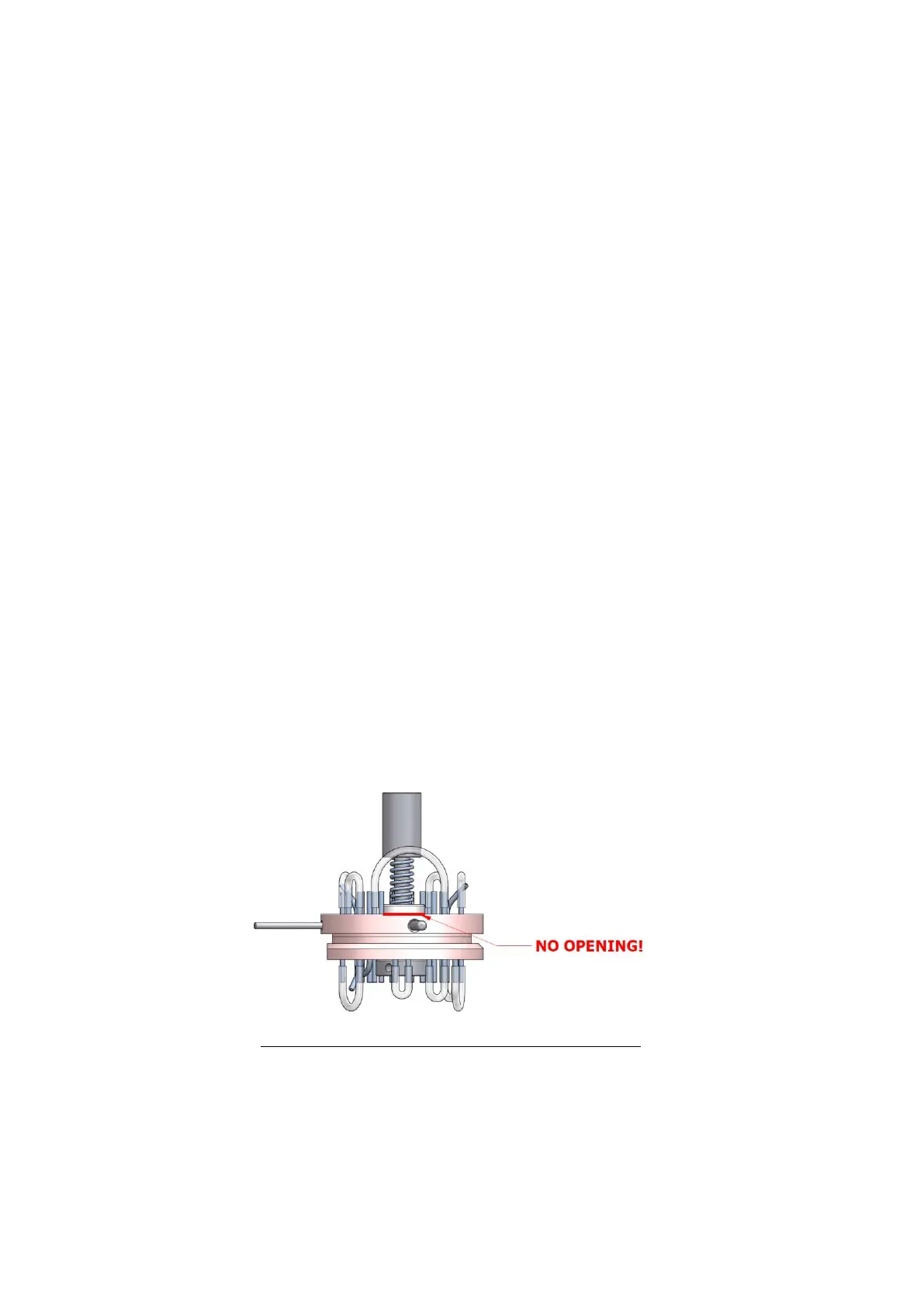

20.3.3.2 Grinding Noise After SV Cleaning, (After SV Reinstallation)

The rotating part cannot reach the opto sensor position – check if the thumb screw is secured correctly

and that there is no gap between the upper and lower discs

20.3.3.3 SV Leakage

The upper disc is not sitting well on the lower disc

Open, and reseat the upper disc

There must not be any opening left between the closing screw and the upper disc

Figure 108. Proper Seating of Shear Valve Thumbscrew

20.3.4 Dilutor Errors

pinched, clogged tube around dilutor or at the rear reagent tubes

physical obstruction (foreign material)

Loading...

Loading...