137

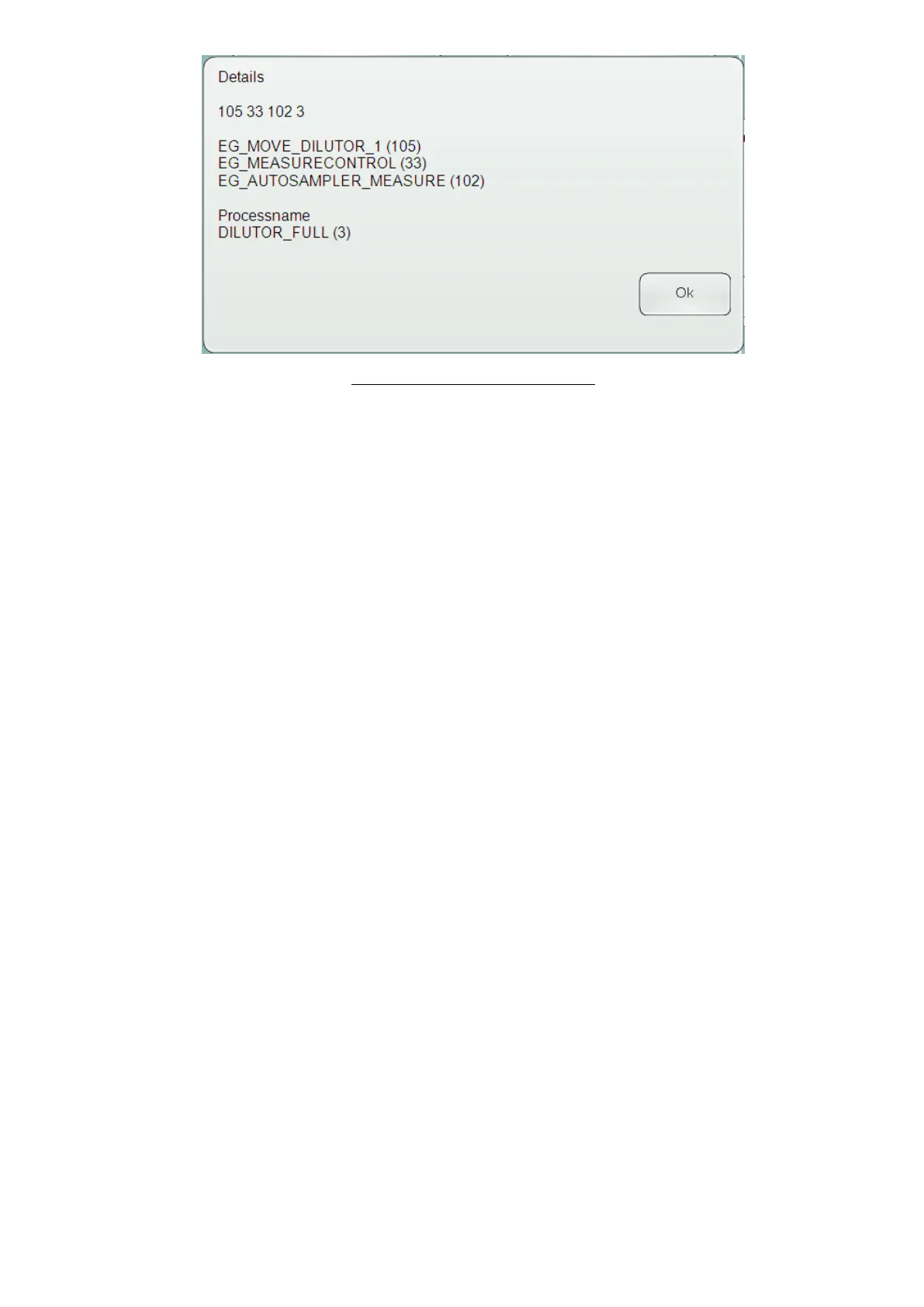

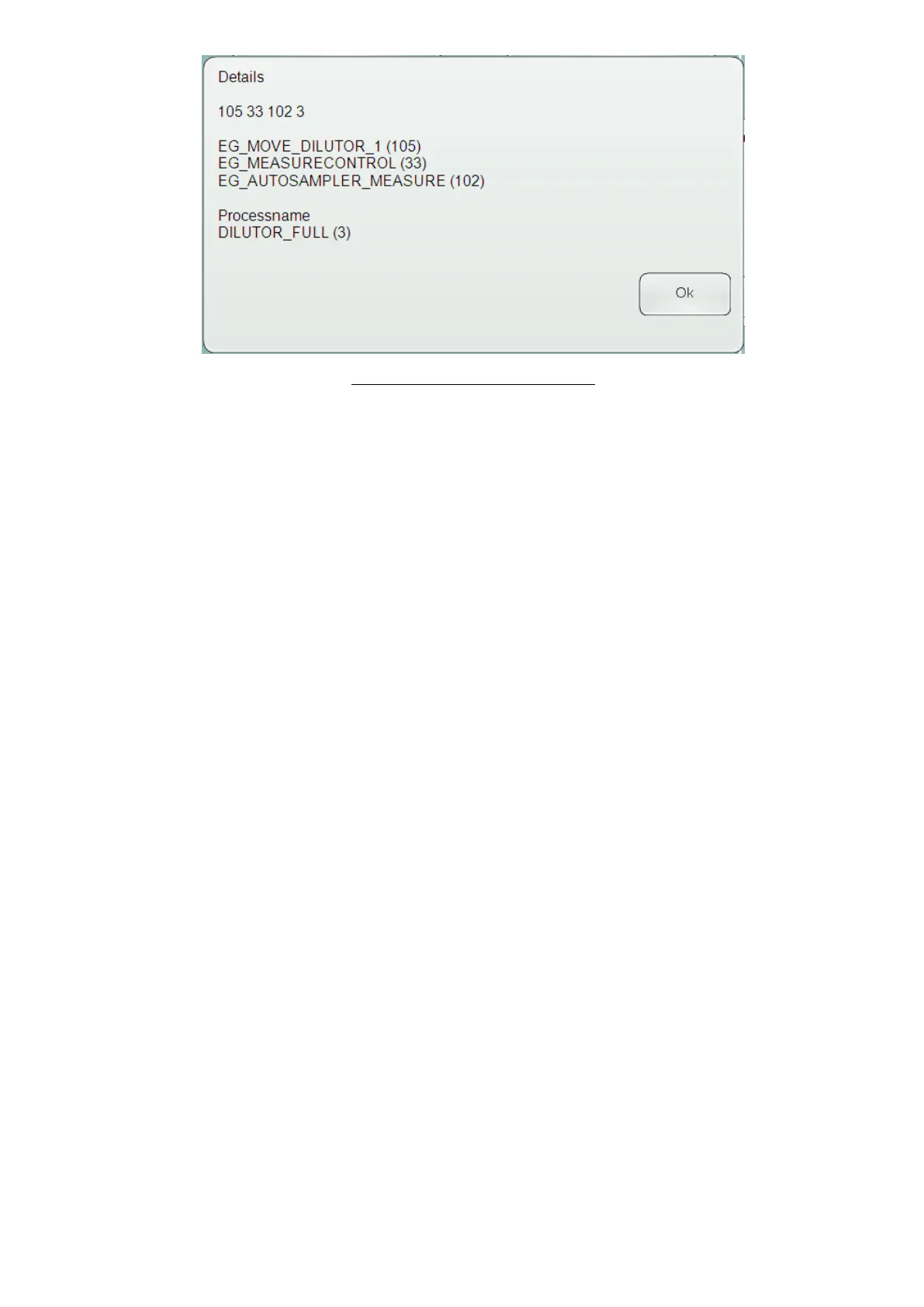

Figure 107. Detailed Error Message

20.3 Mechanical Problems

Most mechanical problems arise because of some physical blockage of the moving parts. Problems caused by

severe blocks are usually accompanied by a grinding noise. The noise is a result of a motor not being able to

move, but this does not usually result in mechanical damage to moving parts.

Typical failure situations can be traced to salt build-ups around the wash head or the shear valve. Incorrect

operation during cleaning of the system, especially after long inactive periods of time can cause valves or tubes to

get filled with dry salt deposits. These problems can be the source of dilutor motor noise.

In extreme tube or valve clogging situations the pressure build-up inside the dilutors can cause some tubes to be

released from their connections. This symptom is not normal, but will not cause damage to the system. However,

it is recommended to contact your service engineer to determine the cause and resolve the problems.

20.3.1 Sample Rotor (SR) Failures

20.3.1.1 SR Gives Grinding Noise And / Or SW Displays SR Error Messages

The front panel is not closed properly

The opening is not aligned with the sample rotor door

There is liquid in the SR, if you can see traces of salt around the SR, contact your service engineer

Check the washing head for contamination (blood and/or salt) as excessive salt build up can prevent the

wash head from lifting up effectively and the sample rotor door can get stuck

20.3.1.2 SR Error Appears During Initialization Process:

Check the washing head for contamination (blood and/or salt)

Contact your service engineer

20.3.1.3 The SR Does Not Turn Into The Analyzer Even With Open Front Panel

check the washing head for contamination (blood and salt)

20.3.2 Needle Mechanics, Vertical Motor (Mvert) Problems

20.3.2.1 The Needle Carriage Keeps Dropping Back (Down) At Initialization

The wash head and surrounding area should be free of salt build-ups

Loading...

Loading...