Note

If you collected data on the measurement point, the Synchronous Analysis Expert uses the original

acquisition settings and adds Synchronous Time averaging. A marked frequency is not used for any

special data acquisition.

Synchronous averaging does not eliminate non-synchronous vibration, it only reduces the

vibration. The amount of reduction depends on the number of averages. Compute the

averages with the following formula:

reaction factor = the square root of the number of averages

For example, if you collect 100 averages, the non-synchronous vibration reduces by a

factor of 10. If you take 10,000 averages, the non-synchronous vibration reduces by a

factor of 100. You get to the point of diminishing returns quickly.

Note

Do not use Synchronous Averaging if important data may be filtered. For example, non-synchronous

energy could identify a rolling element bearing defect.

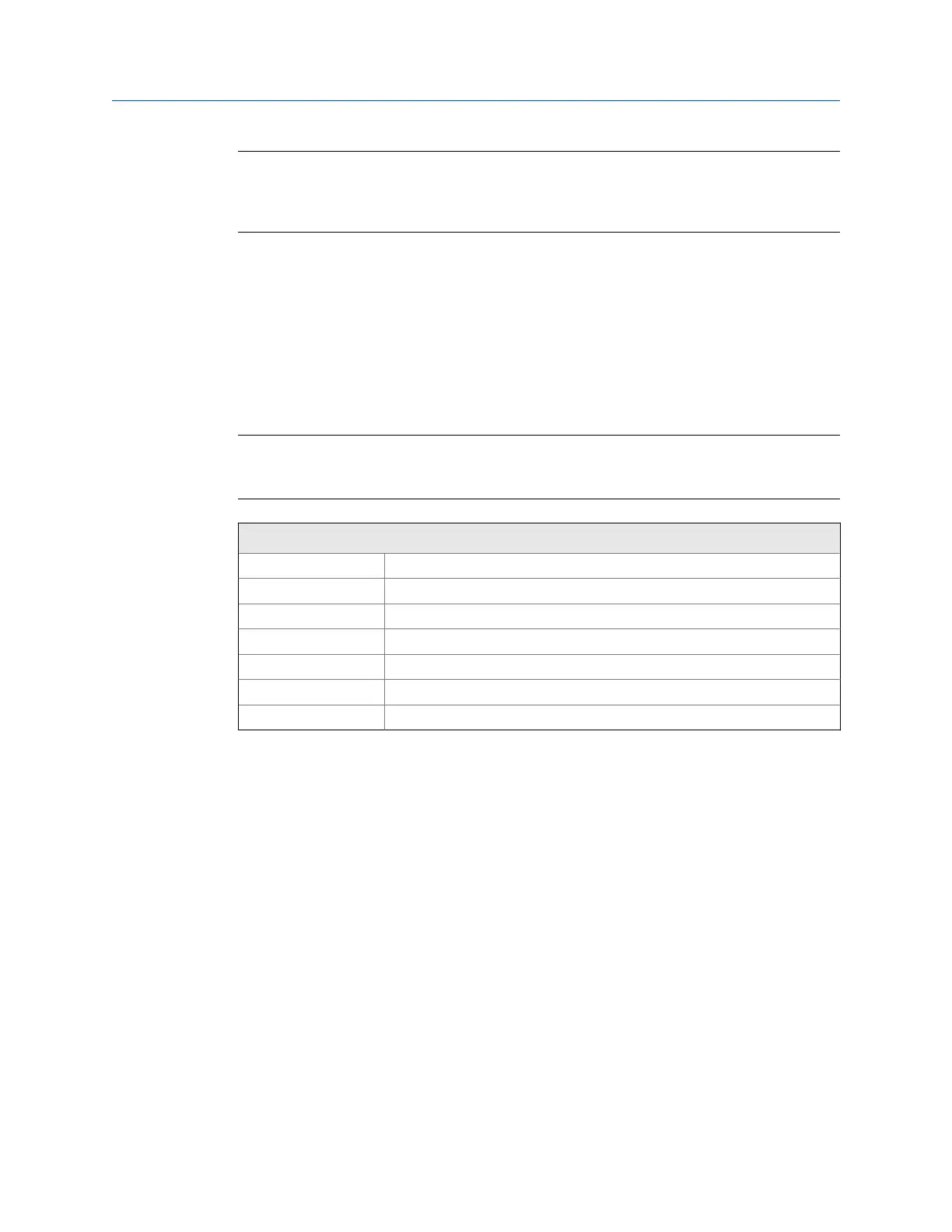

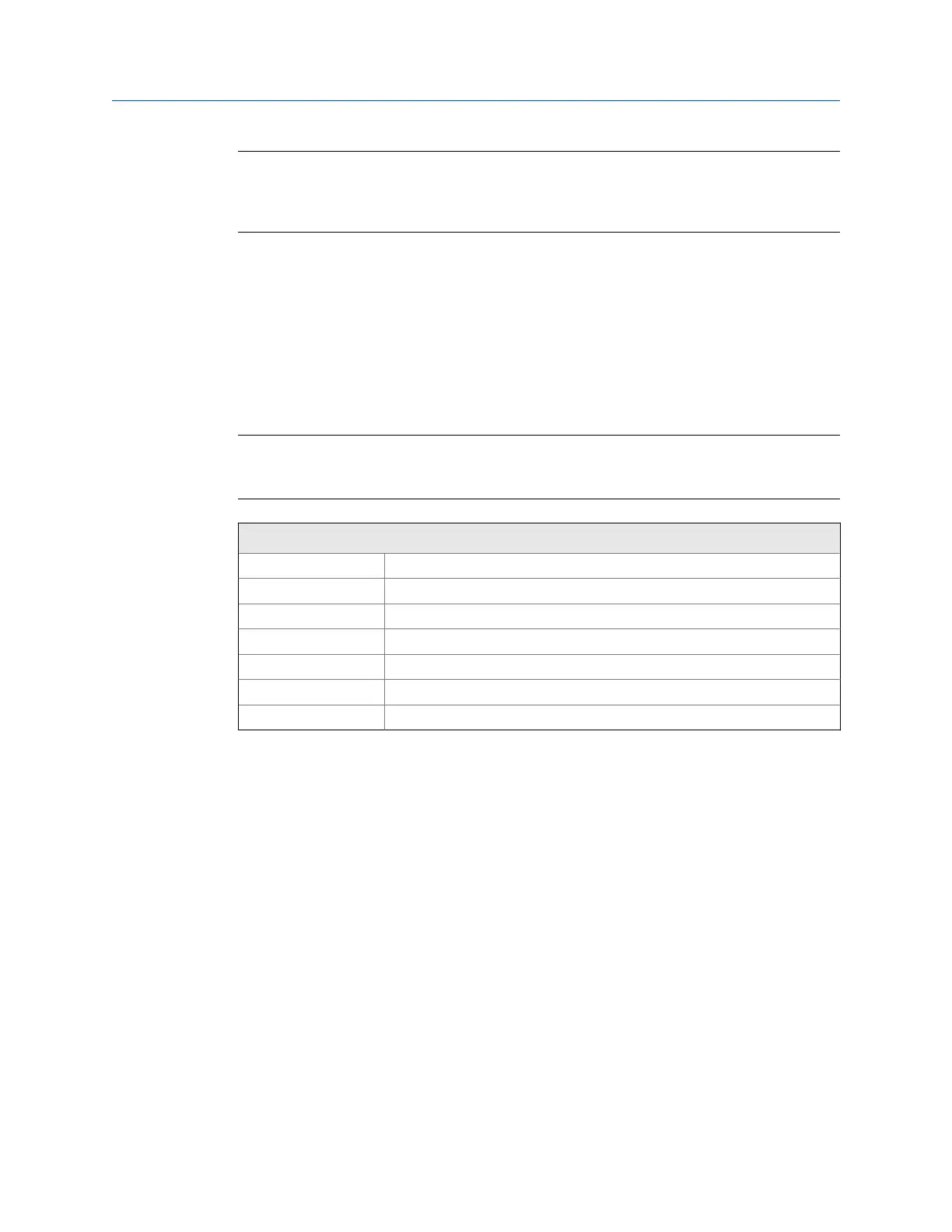

Recommended parameters

Fmax 200 Hz

Low Cutoff 0

Lines 400, but limited to 1600

Window Hanning

Average Count 100

Average Type Synchronous

Trigger Mode Tach

After completing the Synchronous Time averaging process, the analyzer displays the

averaged spectrum.

Synchronous Time averaging adjusts for speed variations of the machine, typically from one

half to twice the initial speed. The averaged spectrum shows the 1x, 2x, and 3x RPM peaks

at a frequency that corresponds to the average machine RPM during the measurement

process.

6.8.18 Orbit Plot

Orbit Plot displays the movement of the shaft centerline for orbit analysis on sleeve

bearings. Orbit Plot requires two or four channels and the turning speed. If you use a

tachometer, the signal is recorded automatically. If the analyzer does not detect a

tachometer signal, enter a turning speed.

Analyze and Advanced Analyze

MHM-97432 Rev 7 135

Loading...

Loading...