Programming manual.

CNC 8070

STATEMENTS AND INSTRUCTIONS

22.

Programming statements

·403·

(REF: 1709)

22.1.11 Spindle synchronization

This mode may be used to set the movement of a spindle (slave) synchronized with that of

another spindle (master) through a given ratio. The spindle synchronization is always

programmed in the channel the slave spindle belongs to, both to activate it or deactivate it

and to reset it.

There are two types of synchronization; in speed and in position. The activation and

cancellation of the different types of synchronization are programmed with the following

instructions.

#SYNC - Spindle synchronization based on the real (actual) coordinate.

#TSYNC - Spindle synchronization based on the theoretical coordinate.

#UNSYNC - Cancellation of spindle synchronization.

#SYNC

Spindle synchronization based on the real (actual) coordinate

#TSYNC

Spindle synchronization based on the theoretical coordinate

The programming format for each of them is the following. Optional parameters are indicated

between the <> characters.

#SYNC [{master}, {slave} <,N{nratio}, D{dratio}> <,O{posync}> <,{looptype}>

<,{keepsync}>][··]

#TSYNC [{master}, {slave} <,N{nratio}, D{dratio}> <,O{posync}> <,{looptype}>

<,{keepsync}>][··]

Each pair of brackets defines a synchronism between two spindles.

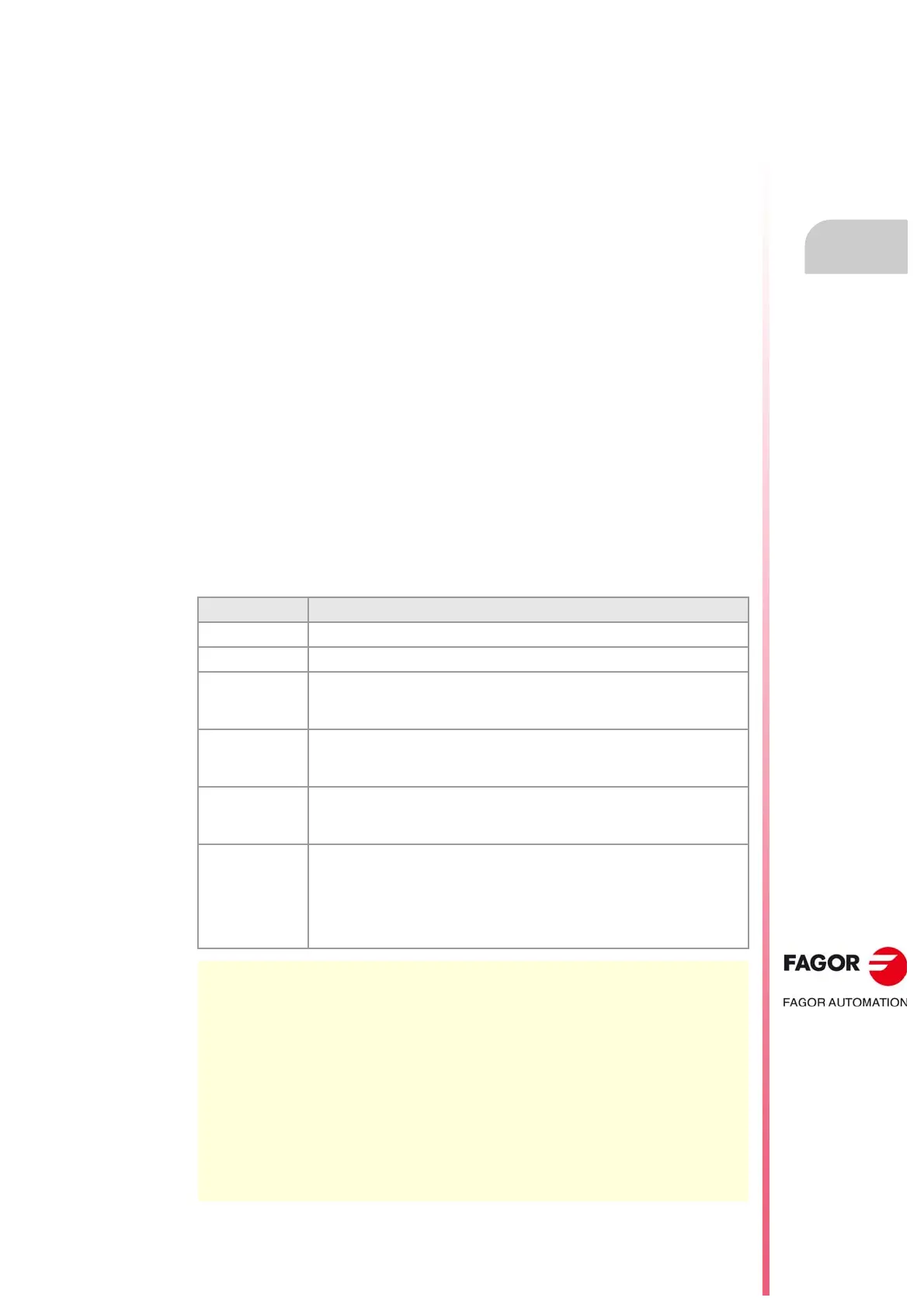

Parameter Meaning

{master} Master spindle of the synchronization.

{slave} Master spindle of the synchronization.

{nratio}

{dratio}

Optional. This pair of numbers define the gear ratio (nratio/dratio) between the

synchronized spindles.

Both values can be positive or negative.

{posync} Optional. This parameter determines that they are synchronized in position and

it also sets the offset (shift) between the two spindles.

The values may be positive or negative and greater than 360º.

{looptype} Optional. This parameter indicates the type of loop for the master spindle.

"CLOOP" for the spindle in closed loop. "OLOOP" for the spindle in open loop.

If not programmed, the statement assumes the value "CLOOP".

{keepsync} Optional. This parameter indicates whether the CNC cancels spindle

synchronization or not after executing M02, M30 or after an error or reset. With

"CANCEL" value, the CNC cancels the synchronism; with "NOCANCEL" value,

it doesn't cancel it.

If not programmed, the statement assumes the value set by the OEM (parameter

SYNCCANCEL).

#SYNC [S,S1]

The spindles are synchronized in speed. The slave spindle S1 turns at the same speed as the

master spindle S.

#SYNC [S,S1,N1,D2]

The slave spindle S1 turns at half the speed (1/2) of the master spindle S.

#SYNC [S,S1,N1,D2,O15]

After synchronizing in speed and in position, the slave spindle S1 follows the master S with the

indicated offset, which could be for example 15º.

#SYNC [S,S1,O30,OLOOP]

Synchronism in speed and position with 30º offset. The master spindle works in open loop.

#SYNC [S,S1,O30,CLOOP, CANCEL]

Synchronism in speed and position with 30º offset. The master spindle works in closed loop. The

CNC cancels the synchronism after M30, an error or a reset.

Loading...

Loading...