Programming manual.

CNC 8070

5.

ORIGIN SELECTION

Coordinate preset (G92)

·86·

(REF: 1709)

5.4 Coordinate preset (G92)

Coordinate presetting is done with function G92 and it may be applied onto any axis of the

machine.

When presetting coordinates, the CNC interprets that the axis coordinates programmed after

function G92 define the current position of the axes. The rest of the axes that have not been

defined with G92 are not affected by the preset.

Considerations

A coordinate preset, by itself, does not cause any axis movement.

When homing an axis in JOG mode, the preset for that axis is canceled.

Function properties

G92 is modal, the preset values remain active until the preset is canceled (with another

preset, a zero offset or with G53).

On power-up, the CNC assumes the coordinate preset that was active when the CNC was

turned off. On the other hand, the coordinate preset is neither affected by functions M02 and

M30 nor by RESETTING the CNC.

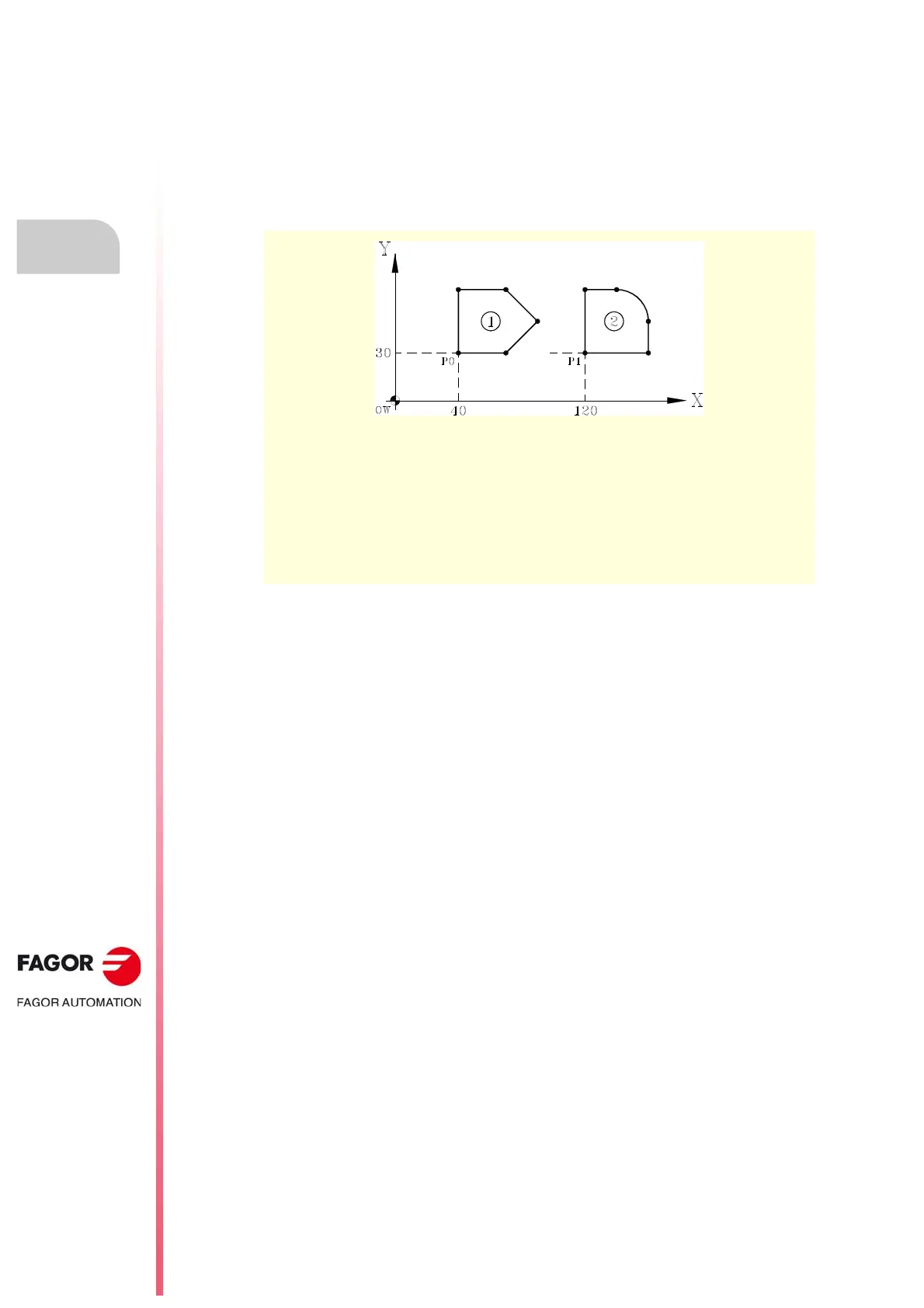

N100 G90 G01 X40 Y30 (Positioning at P0)

N110 G92 X0 Y0 (Presetting P0 as part zero)

... (Machining of profile 1)

N200 G90 G01 X80 Y0 (Positioning at P1)

N210 G92 X0 Y0 (Presetting P1 as part zero)

... (Machining of profile 2)

N300 G92 X120 Y30 (Recovering OW as part zero)

Loading...

Loading...