Programming manual.

CNC 8070

1.

CREATING A PROGRAM.

List of statements and instructions.

·44·

(REF: 1709)

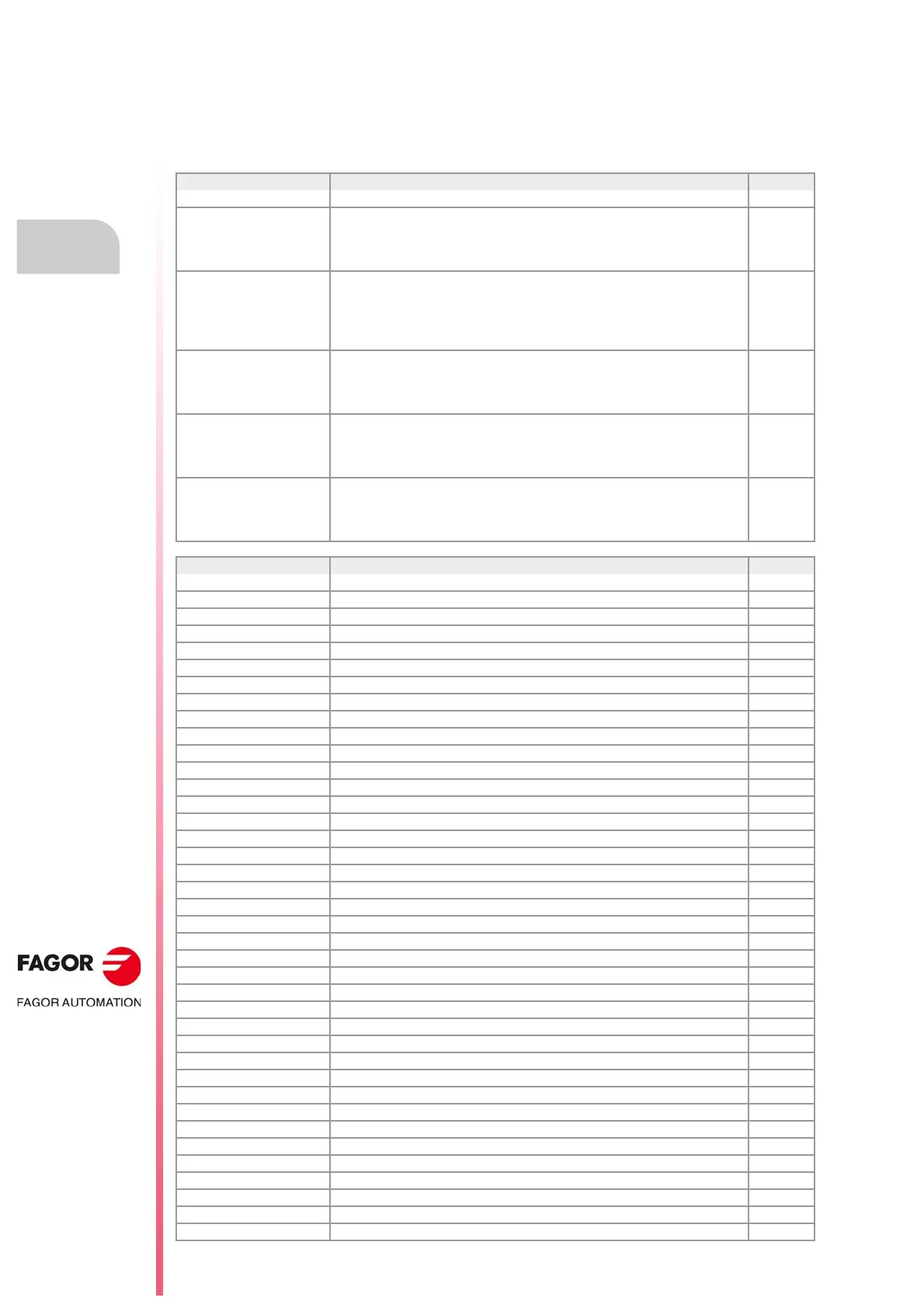

1.7 List of statements and instructions.

The following tables show a list of statements and instructions functions available at the CNC.

Next to each of them, it indicates which chapter of this manual describes it; if no chapter is

indicated, the function is described in another manual.

Instruction Meaning

$GOTO Block skip. 22.2.1

$IF

$ELSEIF

$ELSE

$ENDIF

Conditional execution. 22.2.2

$SWITCH

$CASE

$BREAK

$DEFAULT

$ENDSWITCH

Conditional execution. 22.2.3

$FOR

$BREAK

$CONTINUE

$ENDFOR

Block repetition. 22.2.4

$WHILE

$BREAK

$CONTINUE

$ENDWHILE

Conditional block repetition. 22.2.5

$DO

$BREAK

$CONTINUE

$ENDDO

Conditional block repetition. 22.2.6

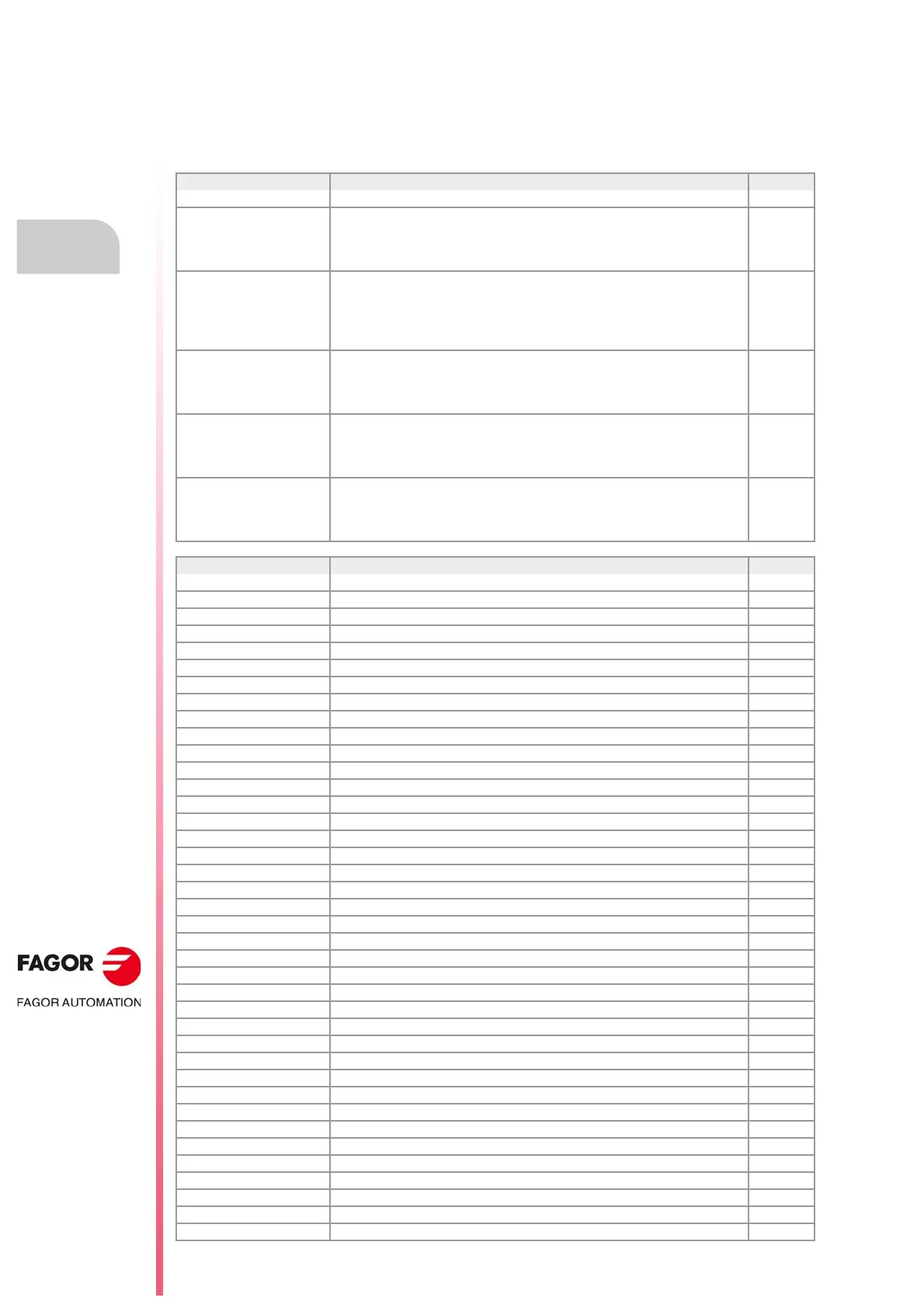

Instruction Meaning

L Call to a global subroutine. 14.3.2

LL Call to a local subroutine. 14.3.1

#ABORT Abort the execution of the program and resume it in another block or program. 15.3

#ACS Fixture coordinate system. 19.4

#ANGAX OFF Turn angular transformation off. 17.1

#ANGAX ON Turn angular transformation on. 17.1

#ANGAX SUSP Freeze angular transformation. 17.2

#ASPLINE ENDTANG Akima splines. Type of final tangent. 22.1.14

#ASPLINE MODE Akima splines. Selection of tangent type. 22.1.14

#ASPLINE STARTTANG Akima splines. Type of starting tangent. 22.1.14

#AXIS Axis upon which the manual intervention is applied. 9.1

#CALL Call to a global or local subroutine. 14.3.3

#CALL AX Add a new axis to the configuration. 22.1.9

#CALL SP Add a spindle to the configuration. 22.1.10

#CAM ON Activate the electronic cam (real coordinates). 22.1.21

#CAM OFF Cancel the electronic cam. 22.1.21

#CAX Axis C. Activating the spindle as C axis. 16.1

#CD OFF Cancel collision detection. 22.1.13

#CD ON Activating collision detection. 22.1.13

#CLEAR Channels. It clears the synchronism marks of the channel. 22.1.19

#CONTJOG Manual intervention. Feedrate in continuous jog. 9.3.1

#COMMENT BEGIN Beginning of comment. 1.8

#COMMENT END End of comment. 1.8

#CS Machining coordinate system. 19.4

#CSROT ON Activate tool orientation in the part coordinate system. 19.9.1

#CSROT OFF Cancel tool orientation in the part coordinate system. 19.9.2

#CYL "C" axis. Machining of the turning side of the part. 16.3

#DEF Macros. Define Macros. 22.1.17

#DEFROT How to manage the discontinuities in the orientation of rotary axes. 19.9.3

#DELETE It initializes the global user variables. 1.9

#DFHOLD Disable the feed-hold signal. 22.1.5

#DGWZ It defines the graphic display area. 22.1.4

#DSBLK End of the single-block treatment. 22.1.5

#DSTOP Disable the cycle stop signal. 22.1.5

#EFHOLD Disable the feed-hold signal. 22.1.5

#ERROR Display an error on the screen. 22.1.1

#ESBLK Beginning of the single-block treatment. 22.1.5

#ESTOP Enable the cycle stop signal. 22.1.5

#EXBLK It executes a block in the indicated channel. 15.2

Loading...

Loading...