Programming manual.

CNC 8070

CREATING A PROGRAM.

1.

List of statements and instructions.

·45·

(REF: 1709)

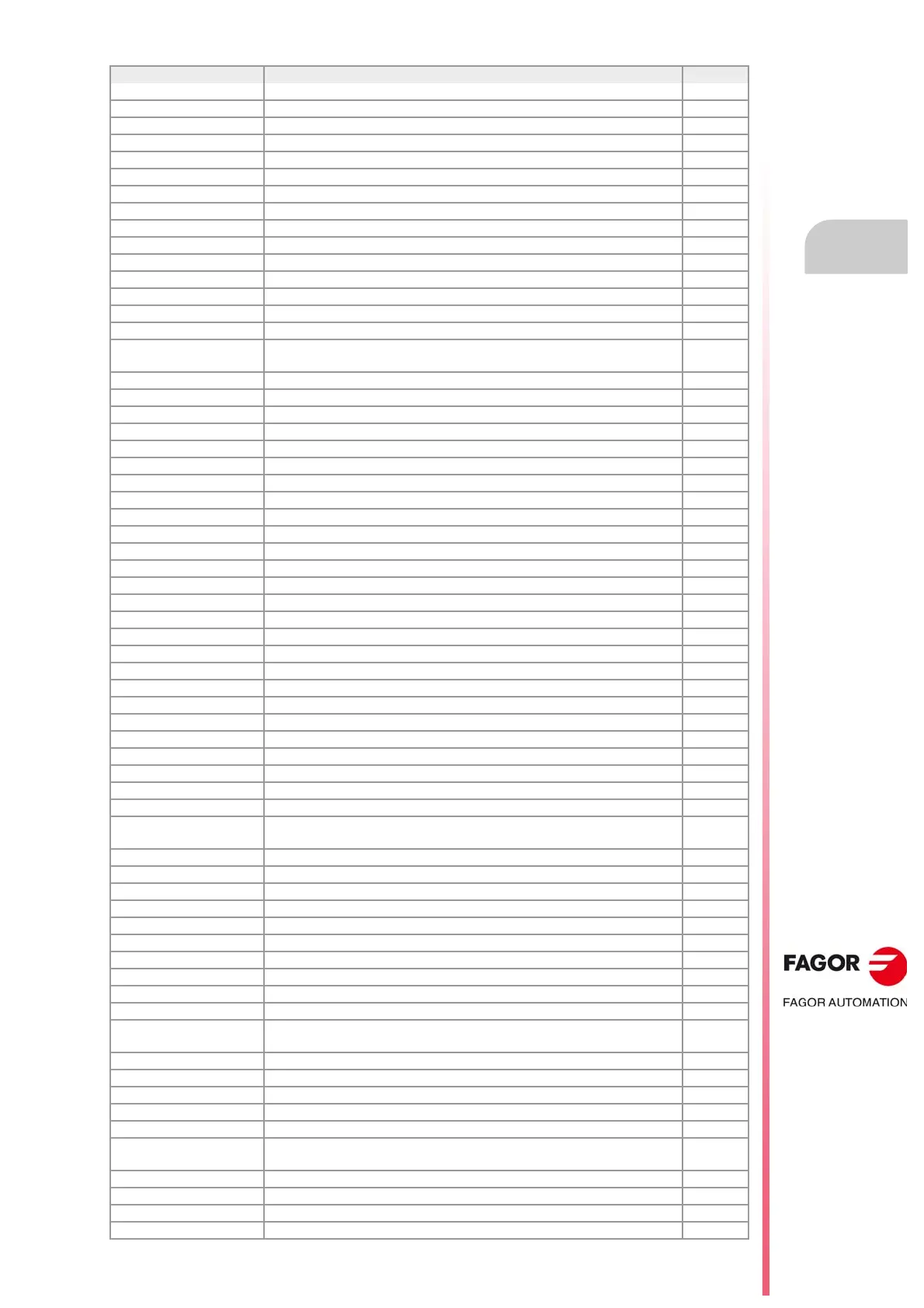

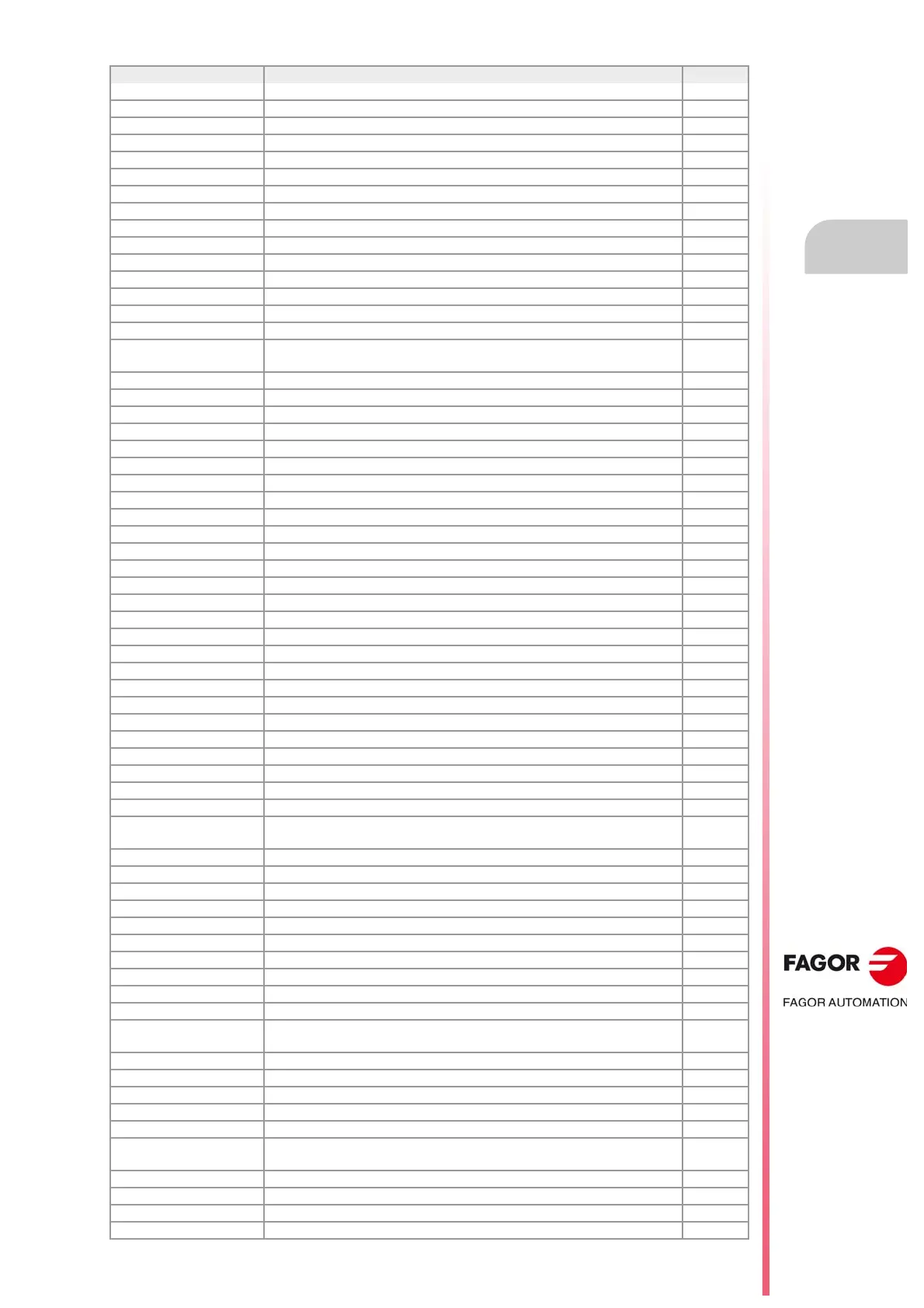

#EXEC It executes a program in the indicated channel. 15.1

#FACE "C" axis. Machining on the face of the part. 16.2

#FEEDND Smooth the path and the feedrate. 12.5

#FLUSH Interrupt block preparation. 22.1.22

#FOLLOW OFF Independent axis. End the synchronization movement. 22.1.20

#FOLLOW ON Independent axis. Begin the synchronization movement (real coordinates). 22.1.20

#FREE AX Free an axis from the configuration. 22.1.9

#FREE SP Free a spindle from the configuration. 22.1.10

#HSC OFF It cancels the HSC mode. 20.6

#HSC ON HSC mode. Optimizing the contouring error. 20.4

#HSC ON [FAST] HSC mode. Optimizing the machining speed. 20.5

#INCJOG Manual intervention. Feedrate in incremental jog. 9.3.2

#INIT MACROTAB Macros. Initialize the table of macros. 22.1.17

#ISO ISO generation. 22.1.6

#KIN ID Select a kinematics. 19.3

#KINORG Transform the current part zero considering the position of the table

kinematics.

19.11

#LINK Activate the electronic coupling (slaving) of axes. 22.1.7

#MASTER Selecting the master spindle of the channel. 7.1.1

#MCALL Modal call to a local or global subroutine initializing parameters. 14.3.5

#MCS Program a movement referred to machine zero. 5.1

#MCS OFF Cancel the machine coordinate system. 5.1

#MCS ON Activate the machine coordinate system. 5.1

#MDOFF Turning the subroutine into non-modal. 14.4

#MEET Channels. It activates the mark in the indicated channel. 22.1.19

#MOVE Independent axis. Positioning move. 22.1.20

#MPG Manual intervention. Resolution of the handwheels. 9.3.3

#MSG Display a message on the screen. 22.1.3

#PARK Park an axis. 22.1.8

#PATH Define the location of the global subroutines. 14.4

#PATHND Smooth the path. 12.5

#PCALL Call to a global or local subroutine initializing parameters. 14.3.4

#POLY Polynomial interpolation. 22.1.15

#RENAME AX Rename the axes. 22.1.9

#RENAME SP Rename the spindles. 22.1.10

#REPOS Repositioning axes and spindles from an OEM subroutine. 14.8.1

#RET End of a global or local subroutine. 14.2

#RETDSBLK Execute subroutine as a single block. 14.3.7

#ROUNDPAR Type of corner rounding. 11.3.1

#ROTATEMZ Positioning a turret magazine. 6.4

#RPT Block repetition. 22.1.18

#RTCP RTCP transformation. 19.6

#SCALE Scaling factor. 11.10

#SELECT ORI Select onto which rotary axes of the kinematics the tool orientation is

calculated for a given direction on the work piece (part).

19.9

#SERVO ON Activates the closed loop mode. 22.1.12

#SERVO OFF Activates the open loop mode. 22.1.12

#SET AX Set axis configuration. 22.1.9

#SET OFFSET Manual intervention. Manual path movement limits.

9.3.4

#SET SP Set spindle configuration. 22.1.10

#SIGNAL Channels. It activates the mark in its own channel. 22.1.19

#SLOPE Acceleration control. 22.1.16

#SPLINE OFF Akima splines. It cancels spline adaptation. 22.1.14

#SPLINE ON Akima splines. It activates spline adaptation. 22.1.14

#SYNC Spindle synchronization. Synchronization of the real coordinate. 22.1.11

#SYNC POS Manual intervention. Synchronization of coordinates and additive manual

offset.

9.3.5

#TANGCTRL OFF Cancel tangential control. 18.1

#TANGCTRL ON Activate tangential control. 18.1

#TANGCTRL SUSP Freeze tangential control. 18.2

#TANGFEED RMIN Minimum contouring radius for applying constant feedrate 6.2.3

#TCAM ON Activate the electronic cam (theoretical coordinates). 22.1.21

#TFOLLOW ON Independent axis. Begin the synchronization movement (theoretical

coordinates).

22.1.20

#TIME Dwell 12.1

#TLC Correct the implicit tool length compensation of the program. 19.7

#TOOL AX Longitudinal tool axis selection. 4.4

#TOOL ORI Tool perpendicular to the inclined plane. 19.5

Instruction Meaning

Loading...

Loading...