Programming manual.

CNC 8070

3.

COORDINATE SYSTEM

Coordinate programming

·68·

(REF: 1709)

3.5.2 Polar coordinates

When having circular elements or angular dimensions, polar coordinates may be more

convenient to express the coordinates of the various points in the plane.

This type of coordinates requires a reference point referred to as "polar origin" that will be

the origin of the polar coordinate system.

Definition of position values

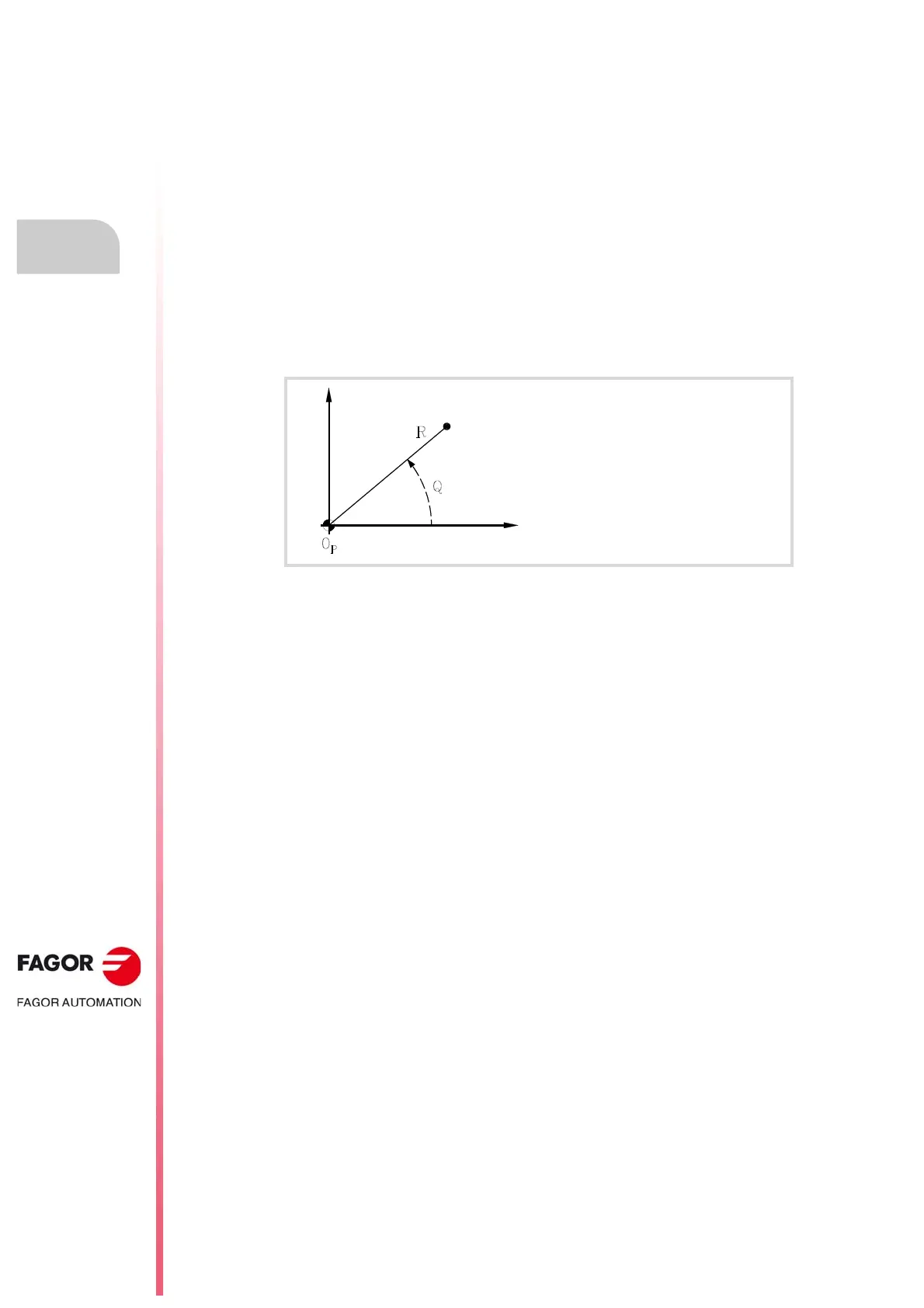

The position of the various points is given by defining the radius "R" and the angle "Q" as

follows:

Radius It will be the distance between the polar origin and the point.

Angle It will be the one formed by the abscissa axis and the line joining the polar

origin with the point.

The radius may be given in mm or in inches whereas the angle is given in degrees.

Both values may be given in either absolute (G90) or incremental (G91) coordinates.

• When working in G90, the "R" and "Q" values will be absolute. The value assigned to

the radius must always be positive or zero.

• When working in G91, the "R" and "Q" values will be incremental. Although negative "R"

values may be programmed, when programming in incremental coordinates, the

resulting value assigned to the radius must always be positive or zero.

When programming a "Q" value greater than 360º, the module will be assumed after dividing

it by 360. Thus, Q420 is the same as Q60 and Q-420 is the same as Q-60.

Polar origin preset

The "polar origin" may be selected from the program using function G30. If not selected, it

assumes as "polar origin" the origin of the active reference system (part zero). See chapter

"5 Origin selection".

The selected "polar origin" is modified in the following instances:

• When changing the work plane, the CNC assumes the part zero as the new "polar origin".

• On power-up, after an M02 or M30 and after an EMERGENCY or a RESET, the CNC

assumes the part zero as the new polar origin.

R Radius

Q Angle

OP Polar origin

Loading...

Loading...