30 User’s Manual INNOMAR Parametric Sub-Bottom Profilers / SESWIN

30 Innomar Technologie GmbH (2023-01)

like the INNOMAR systems. A small positive inclination (bow up, max. 0.5°) is acceptable in order

to ensure laminar water flow. Avoid negative inclination since this may cause turbulences.

Electrical connection / grounding: To reduce noise caused by the mains generator the

transducer’s housing should be electrically connected to the topside unit by an additional ground

wire.

Prevent bio-fouling: To reduce bio-fouling, hull-mounted transducers have to be painted with an

approved water-based anti-fouling compound, see below.

Prevent corrosion: If the transducer is situated in water for a longer period of time, use zinc

anodes to prevent corrosion. Proper grounding is also essential.

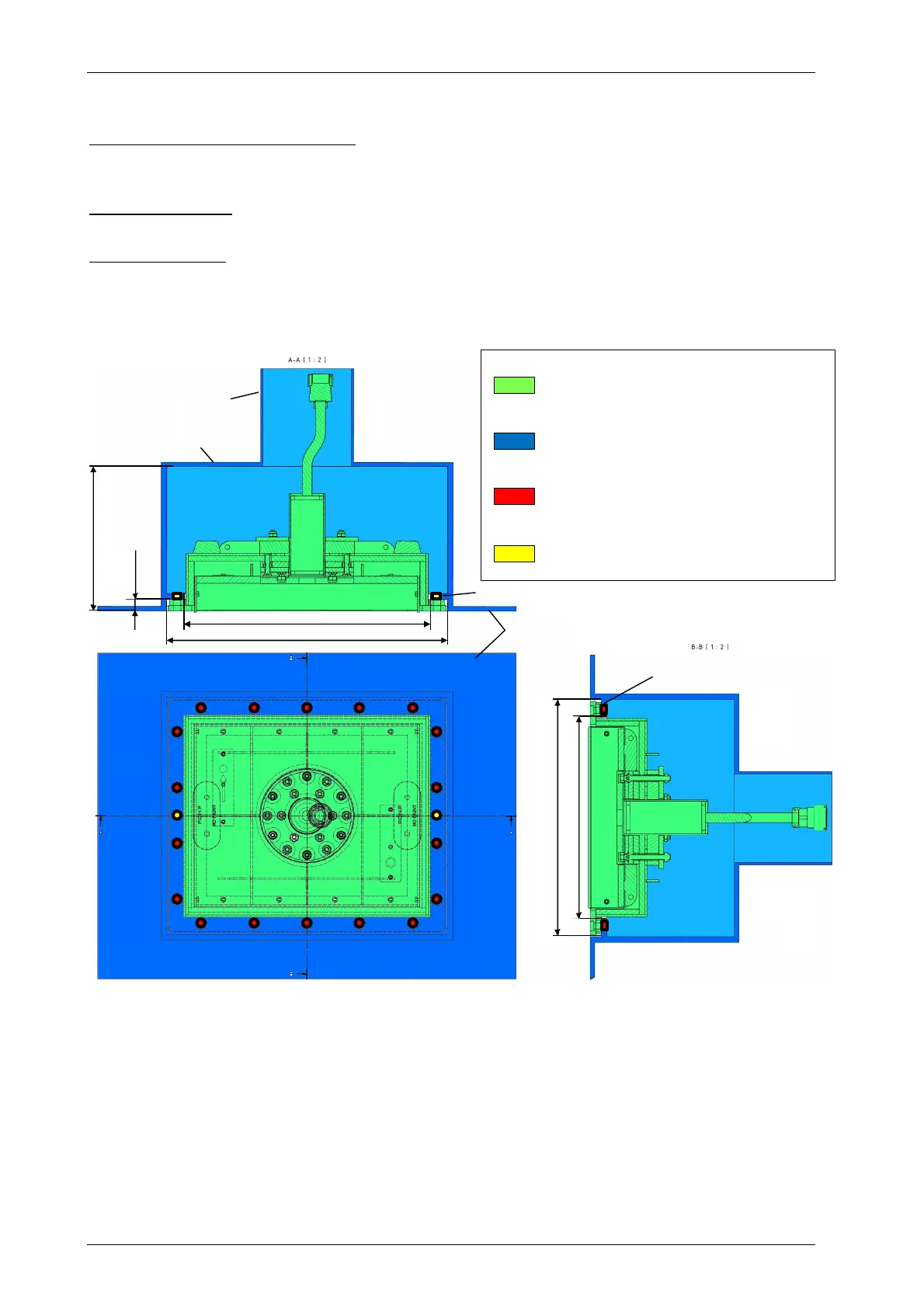

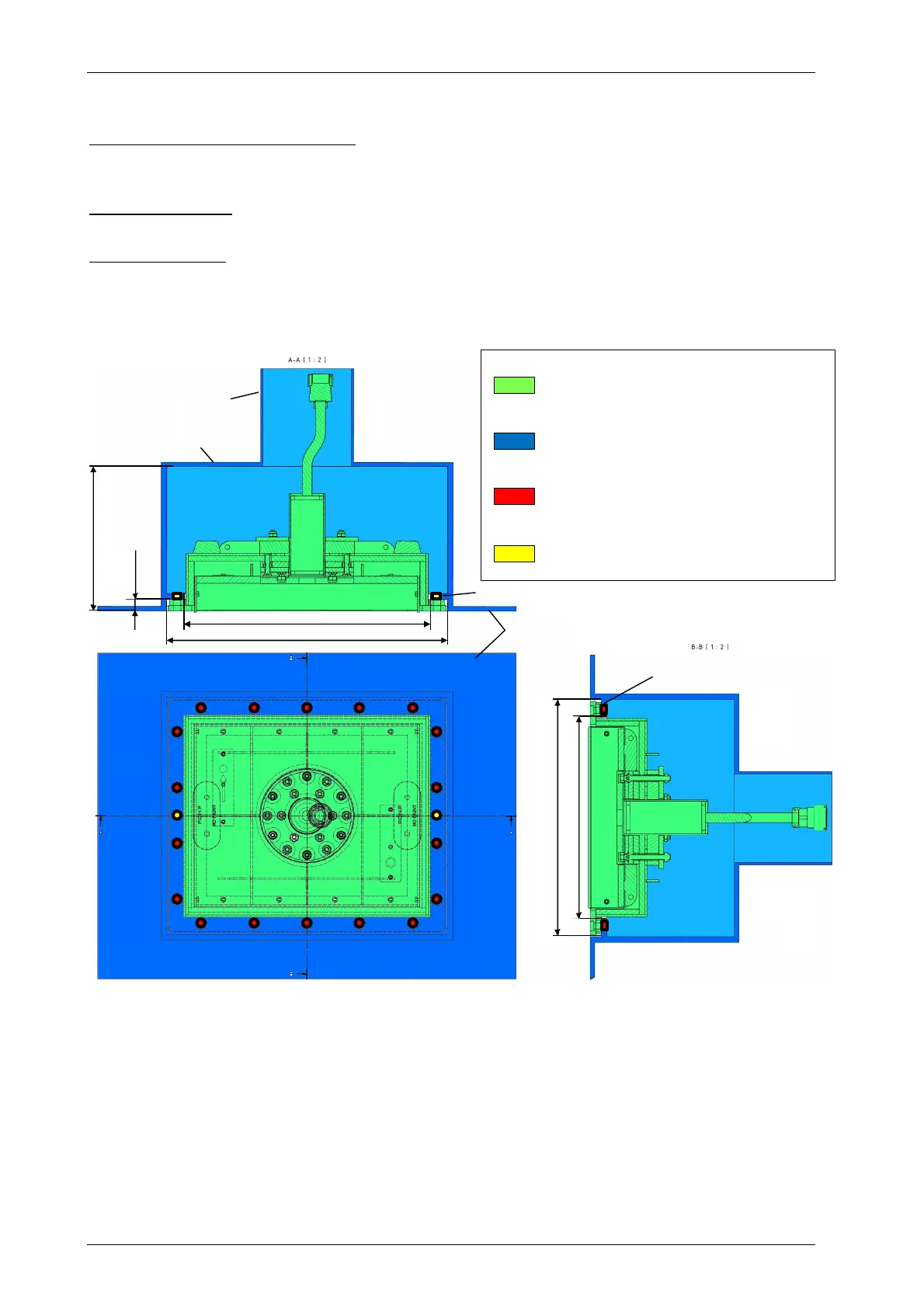

Sea Chest / Gondola Preparation

Sketch showing the INNOMAR “medium-100” hull-mount transducer with mounting frame as delivered by Innomar

(green parts) and all parts to be prepared by the ship yard: sea chest with mounting flange and stand pipe (blue),

threaded holes M10 (red) and water inlet holes (yellow) in the mounting flange.

To affix the transducer there are threaded holes (or drilled holes with hex nuts welded on top) in

the flange (marked red in the sketch above). There are also two water inlets (marked yellow) in

the flange to ensure the sea chest is flooded. Innomar provides a drilling template for all

holes/threads in the flange. The holes should be drilled after welding the flange. The drilling

template can also be used to verify if the transducer fits into the rectangular cut-outs.

Legend

Transducer with mounting frame

and cable (provided by Innomar)

Sea chest, stand pipe, flange

(ship yard)

Threaded mounting holes M10 in flange

(ship yard)

Water inlet holes in flange (ship yard)

stand pipe

sea chest

mounting flange

vessel hull

mounting flange

Loading...

Loading...