User’s Manual INNOMAR Parametric Sub-Bottom Profilers / SESWIN 89

Innomar Technologie GmbH (2023-01) 89

7 How To ...

7.1 How to avoid the engine’s noise / proper transducer mounting

General hints about transducer mounting are given in section 3.2 on page 26. The ship’s engines

often cause mechanical vibrations of the entire hull of the ship. These vibrations can go to the

transducer via its support and the hull can emit sound that causes noise in the SBP receiver, too.

The frequency range of the vibrations depends on several facts, like the vibration source and the

resonance frequencies of the mechanical parts, for example the mounting pipe. Although the

received signal is bandpass-filtered in the INNOMAR SBP, there may be still undesired frequency

components within the used frequency range caused by the vibrating engine.

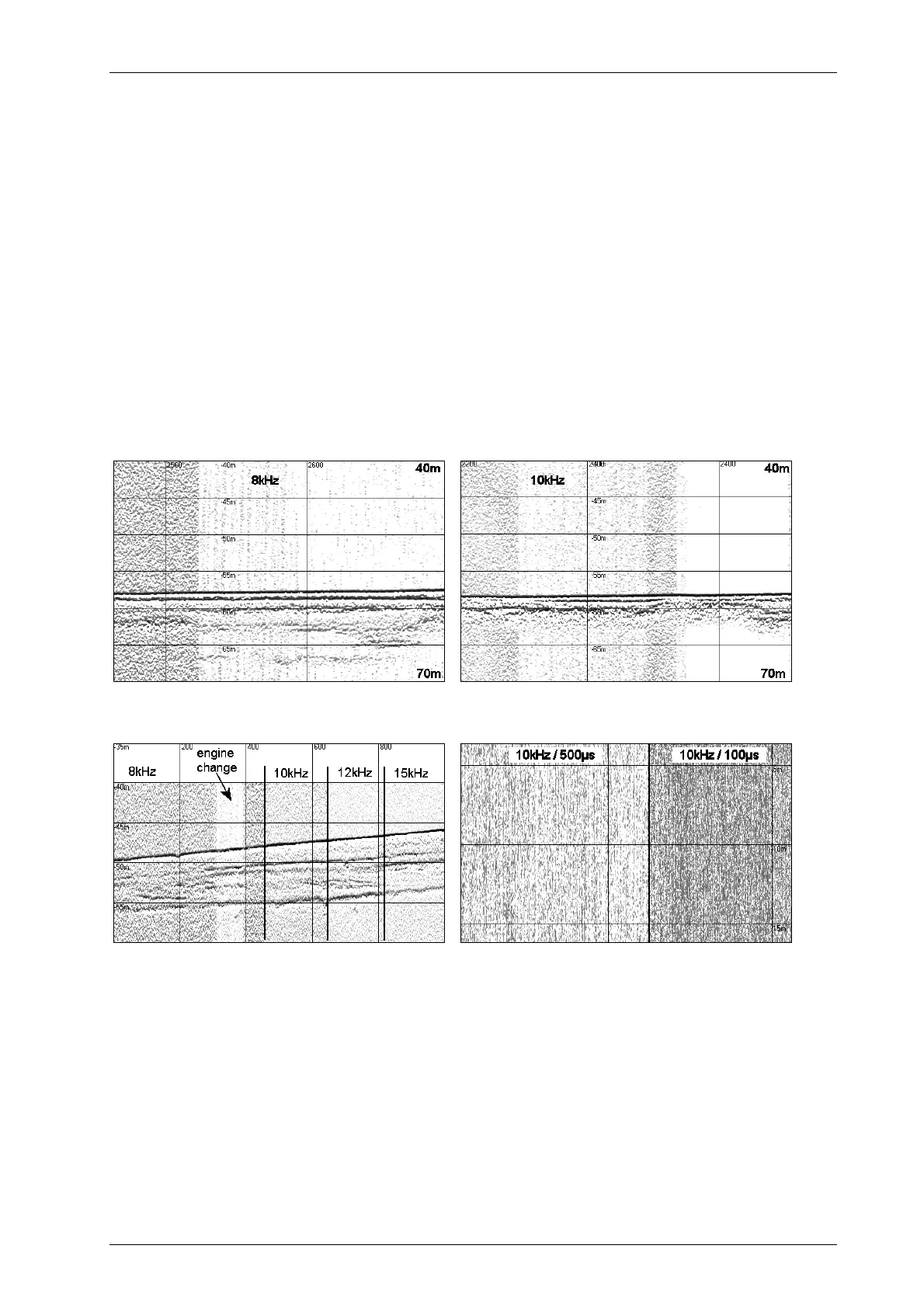

The engine’s influence to the noise level for an unfavourable transducer mounting (close to the

engine) is illustrated in the figures below. There is a dramatic change in the noise level when

changing the revolution speed of the engine. From these figures, also a frequency dependence

of the noise level can be seen. Since the engine’s noise is mainly below 6 kHz and the receiver

signals are band-limited according to the bandwidth of the transmitted pulse, the signal-to-noise

ratio (SNR) gets better when the frequency and/or the pulse length is increased.

Engine revolution speed dependence of the noise level (gain constant 46 dB, pulse length 500 µs):

The SNR gets better with decreasing revolution speed. The noise level decreases with increasing centre frequency.

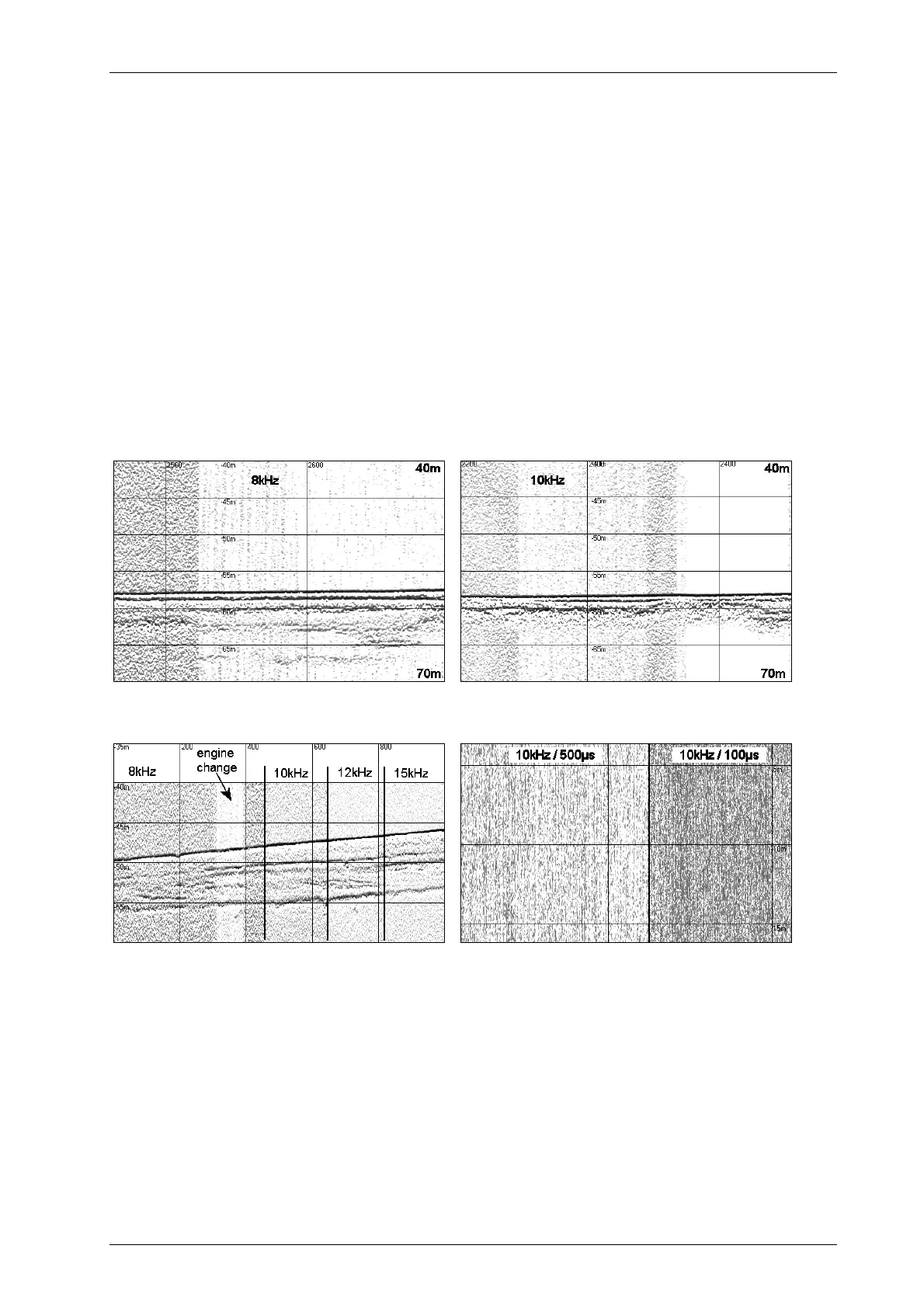

Frequency and pulse length dependence of the noise level (speed and gain constant)

left: pulse length constant 500 µs; The SNR gets better with increasing frequency.

right: frequency constant 10 kHz; The SNR gets better with increasing pulse length.

To avoid interferences with the noise that is produced by ship’s engine the transducer should

be placed as far away as possible from the engine. Since the engine (and the propeller) is at

the rear end of the ship, the transducer should be placed at the front half of the ship. At small

boats the best place for the transducer is at the bow.

To avoid the impact of noise by vibrations onto the transducer it should be mechanically

decoupled from the vessel. Especially the steel-to-steel connections on the flange and on the

pipe should be decoupled using elastic material like rubber, plastics or wood.

Loading...

Loading...