7-2

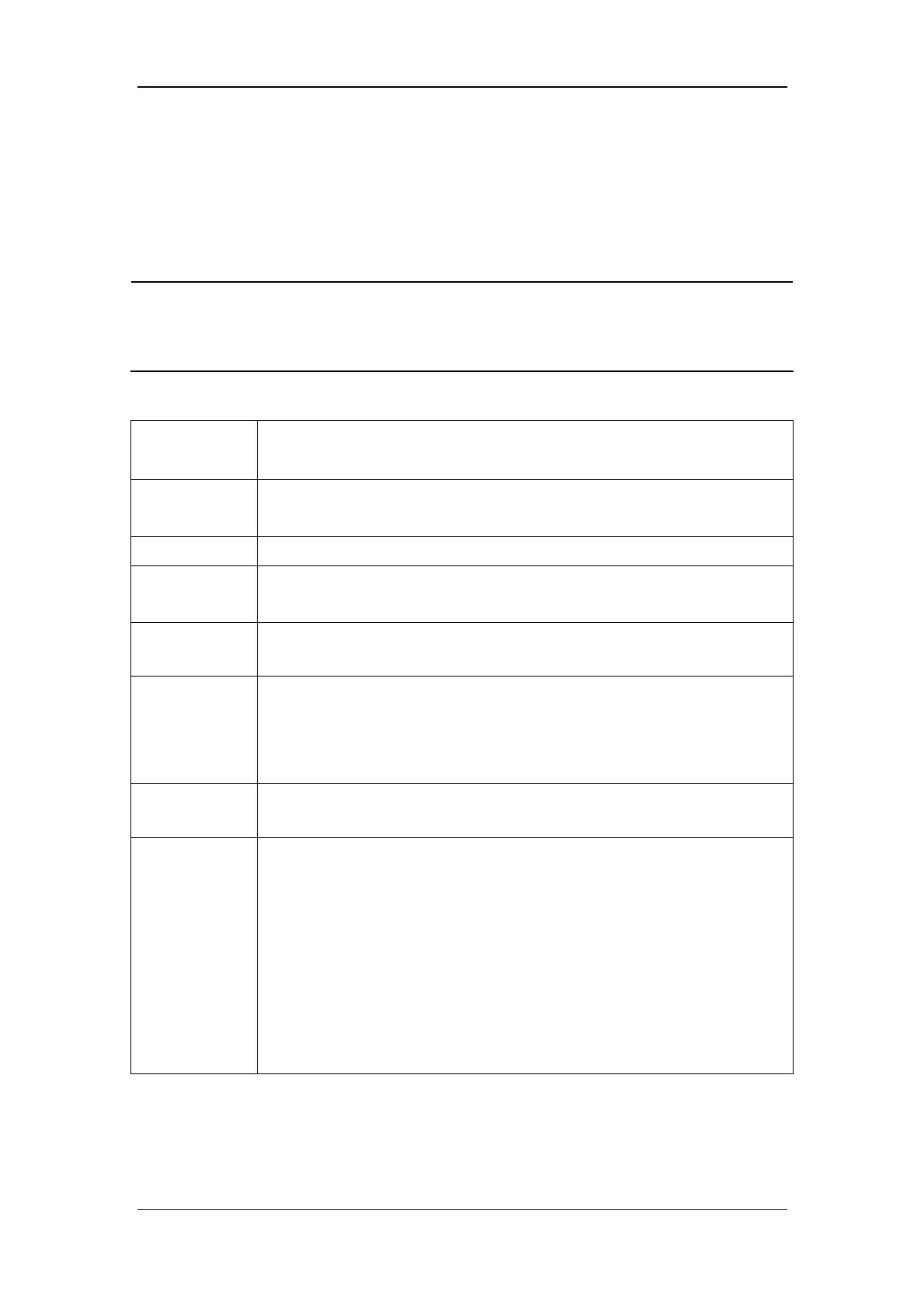

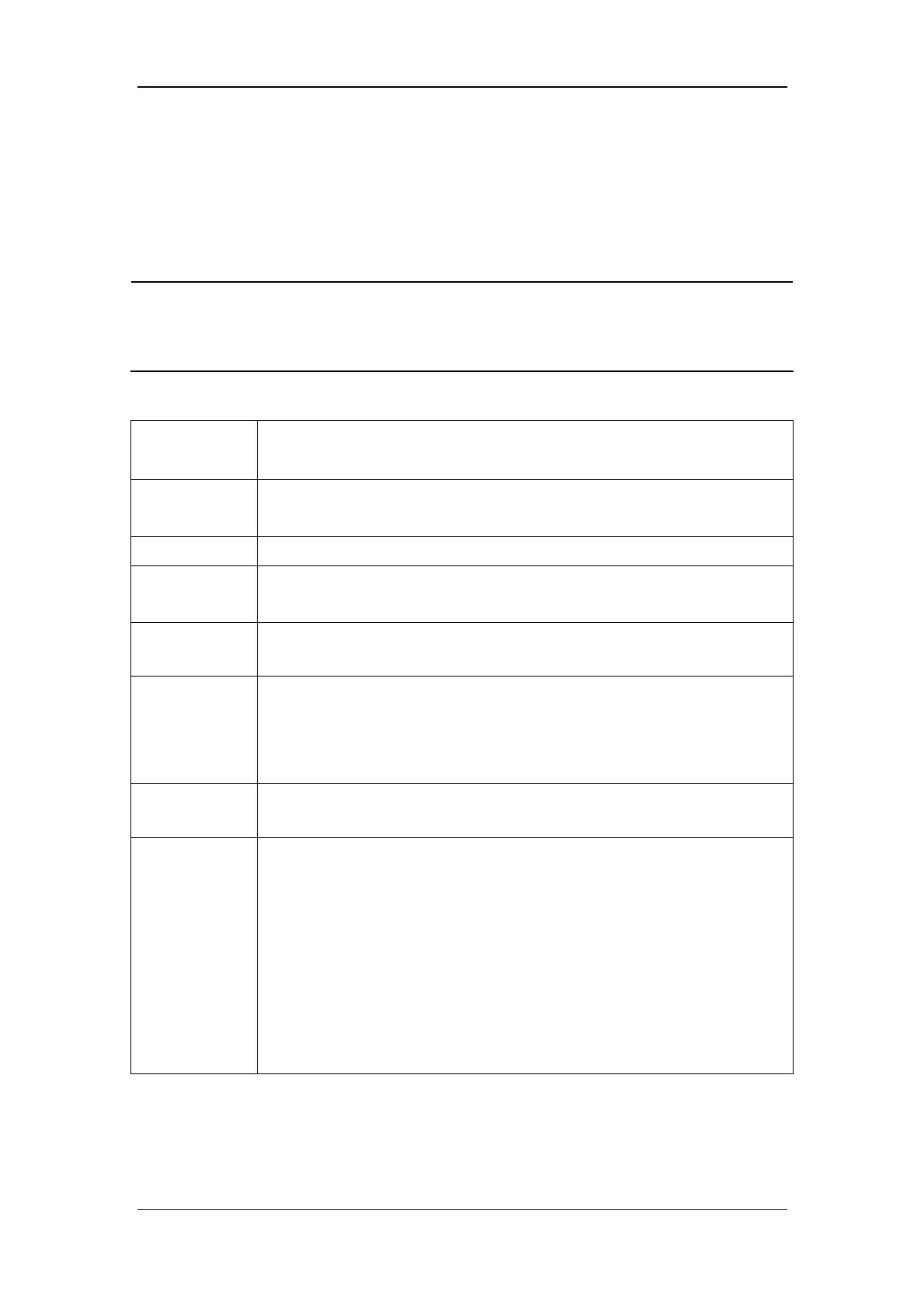

7.2 Maintenance Schedule

NOTE

z These schedules are the minimum frequency based on typical usage of 2000 hours

per year. You should service the equipment more frequently if you use it more than

the typical yearly usage.

Minimum

frequency

Maintenance

Daily

Clean the external surfaces.

21%O2 calibration (O

2

sensor in breathing system).

Biweekly Drain the vaporizers.

Monthly

100% O

2

calibration

(breathing system O

2

sensor).

Clear water built up inside the waterstraps of CO2 module and AG module.

During cleaning

and setup

Inspect the parts and seals for damage. Replace or repair as necessary.

Annually

Replace the seal on the vaporizer manifold and that on the breathing system

port. Contact us for details.

CO2 module calibration.

AG module calibration.

Every three

years

Replace the built-in lithium-ion batteries. Contact us for details.

As necessary

Before installing the cylinder, use a new cylinder gasket on cylinder yoke.

Empty the water collection cup If there is water built up in it.

Replace the sodalime in the canister if sodalime color change is detected.

Replace the O2 sensor if a great deviation of the measured value by the O2

sensor occurs and the problem persists after multiple calibrations.

Replace the flow sensor if the seal for the flow sensor is damaged, the

membrane inside the flow sensor is cracked or distorted, or the flow sensor is

cracked or distorted.

Replace the transfer tube if it is damaged.

Loading...

Loading...