Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 149 of 909

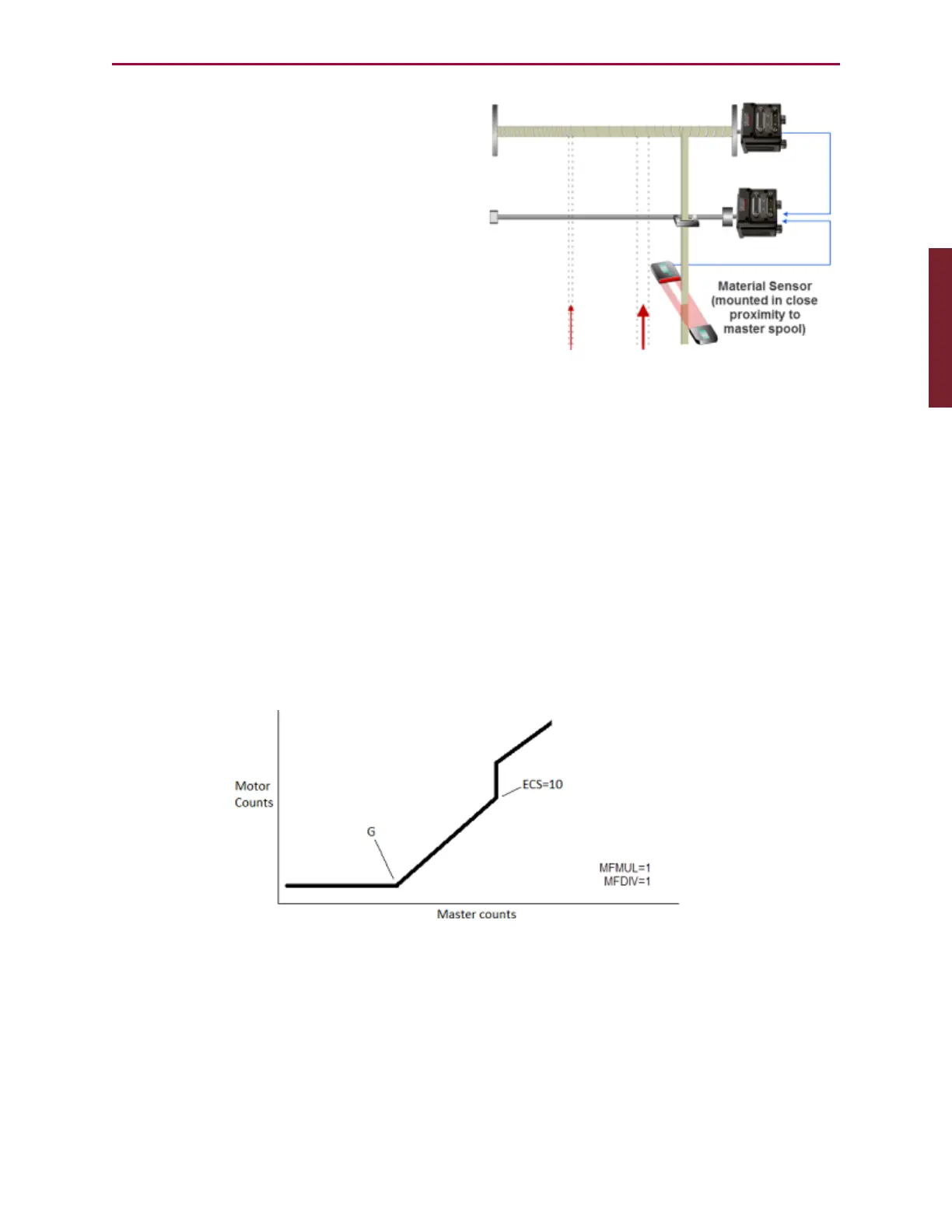

Proper use of the ECS command will allow

full packing of material onto a spool

regardless of variance in material width.

1.

A sensor reads the material width.

2.

Through programming, the user will

scale value to encoder counts.

3.

Based on encoder counts, the

traversing SmartMotor will have ECS

(encoder counts) issued, which results

in a change to incoming master counts

by that value.

4.

The SmartMotor adjusts its gearing.

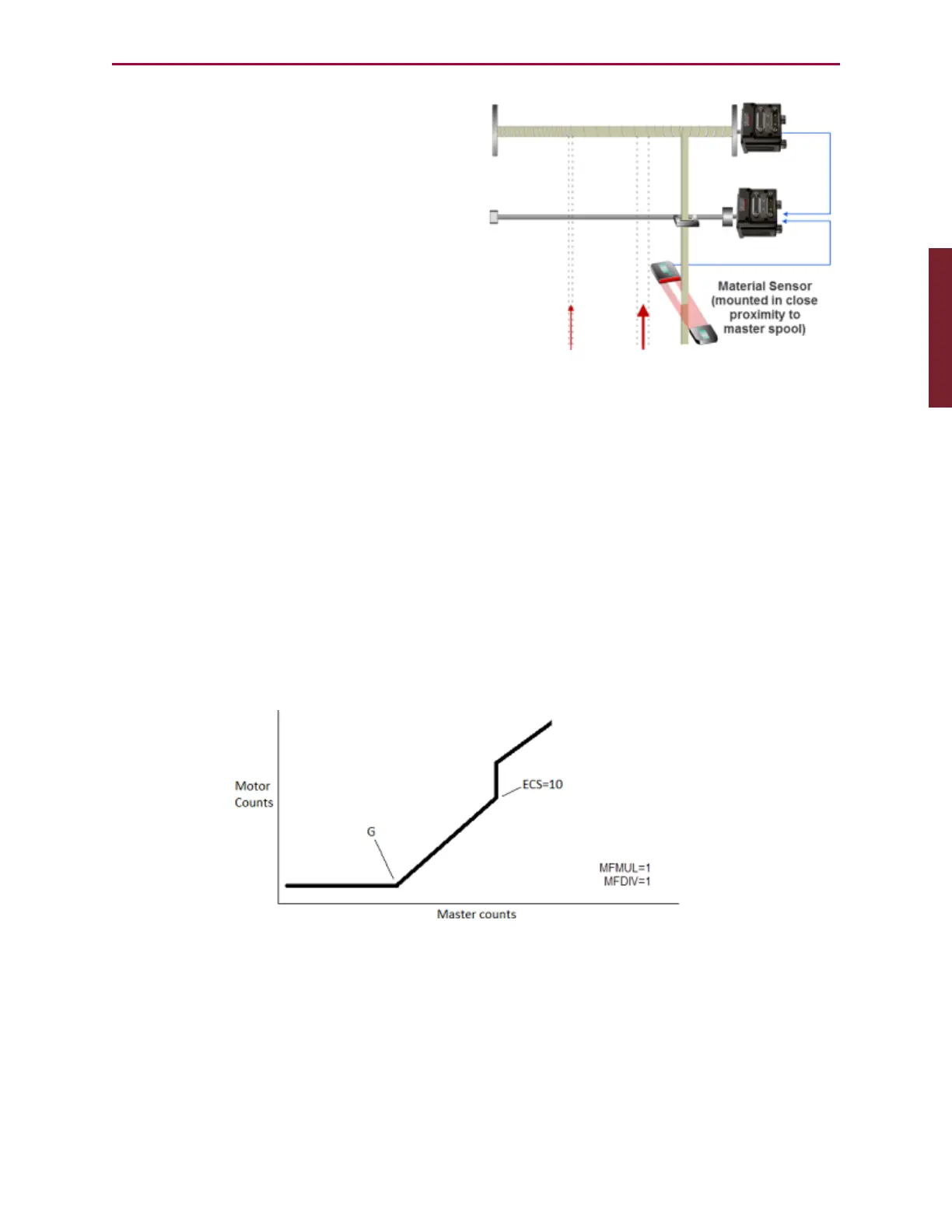

The ECS command is for tiny continuous corrections, where changing MFMUL or MFDIV is not

desired because the basic ratio needs to remain fixed, but changes in demand for correction

may need to be adjusted over time. For example, assuming you have a program with normal

gearing:

MFMUL=1 'Ratio (default is 1)

MFDIV=1 'Ratio (default is 1)

MFR 'Enable follow mode

G 'Begin move.

In this case, the motor begins spinning at a 1:1 ratio of external encoder input. Then you

issue:

ECS(10) 'Encoder count shift of 10 counts

The motor will lunge forward by 10 encoder counts, as shown in the following figure.

Change Caused by ECS Command

However, if MFMUL=100 and MFDIV=1 (100:1 ratio), the motor would lunge forward by 1000

counts because the ratio is multiplied by the ECS value. In this case, if EL(Error Limit) was set

to 1000 or less, the change from ECS would cause an instantaneous following error. It could

also cause peak overcurrent errors.

Part 1: Programming: ECS(counts)

Loading...

Loading...