Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 143 of 909

The ENCD() command can be used over the Combitronic network.

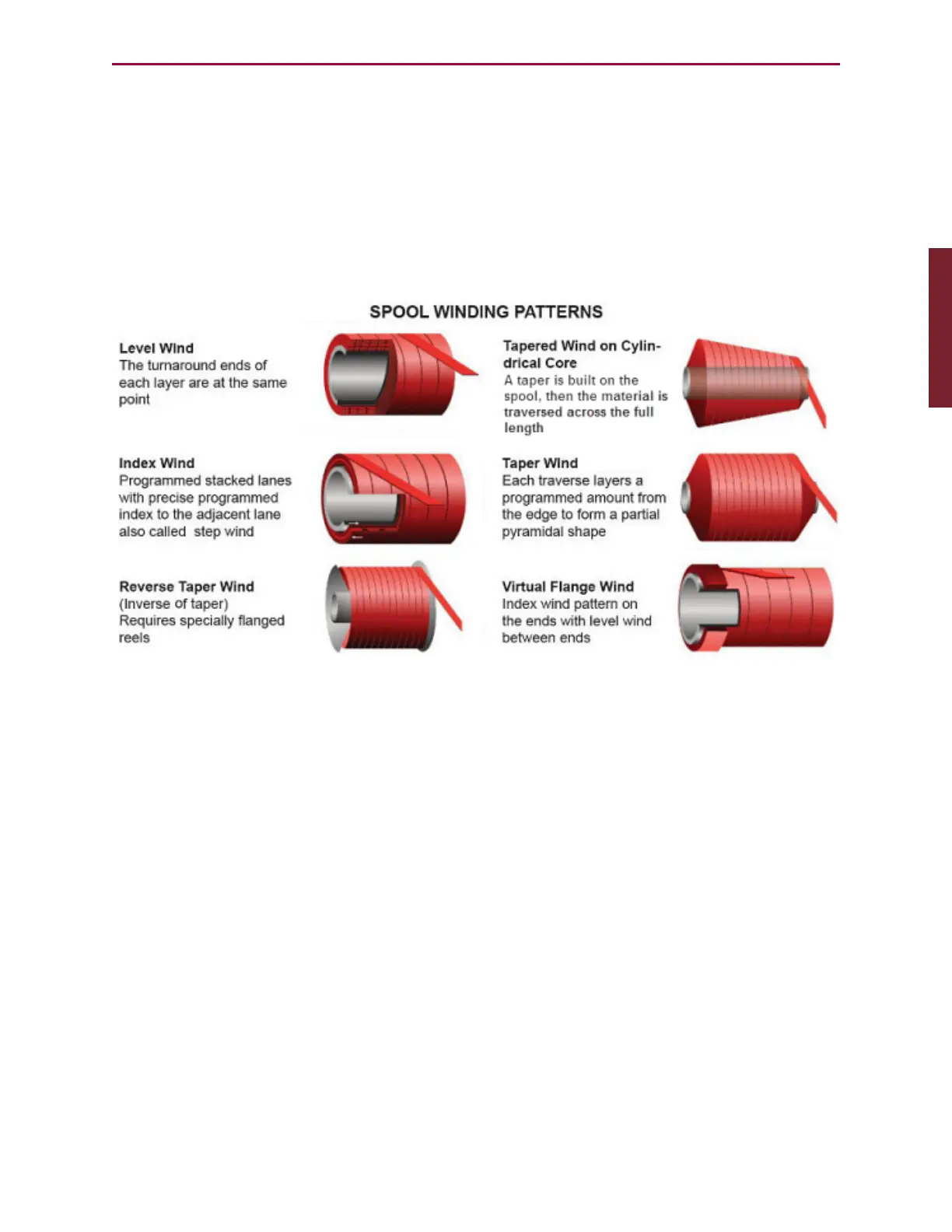

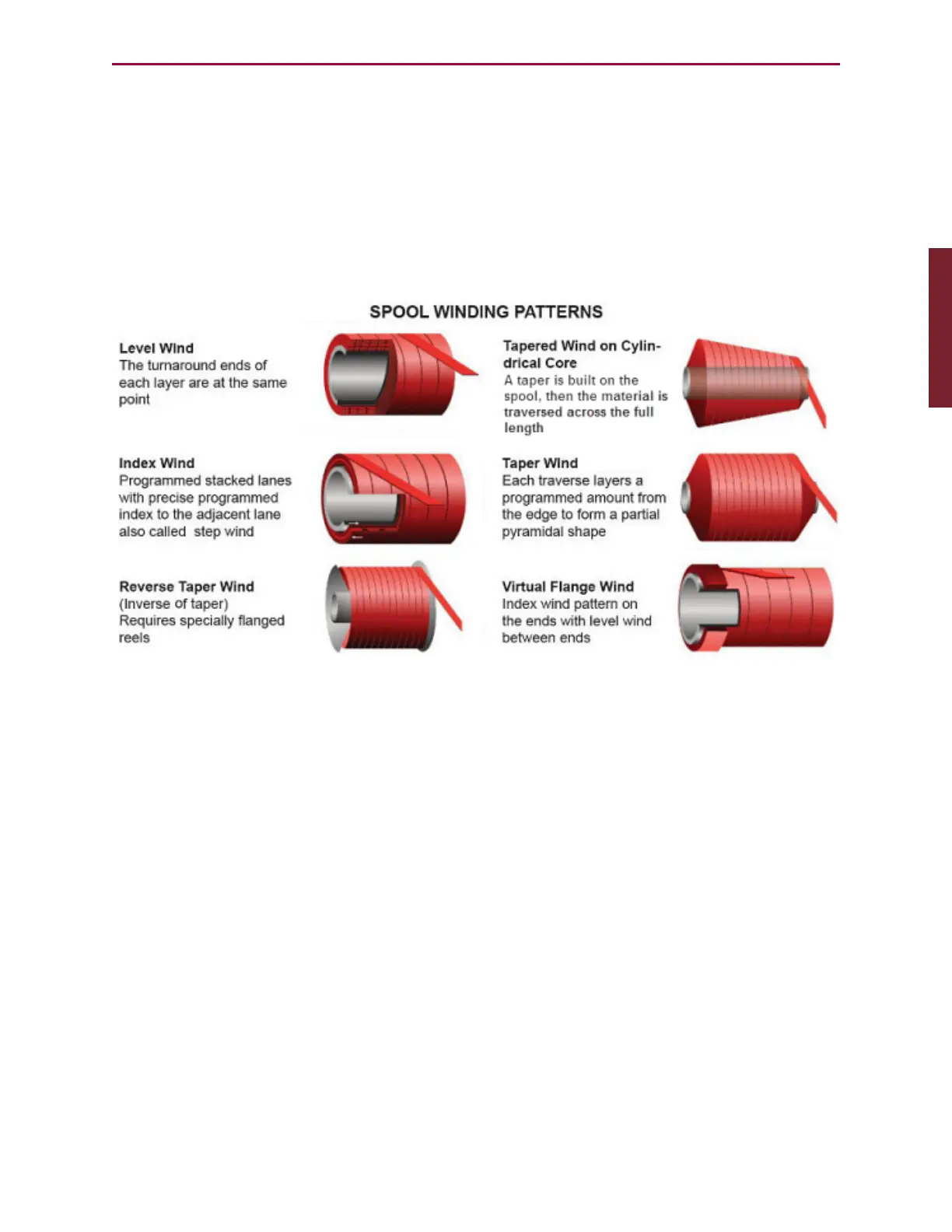

Spooling and Winding Overview

Spooling or winding provides a cost-effective way to package materials of very long length,

such as thread, film, labels, cable and thermoplastics. The material is fed from a large spool

at a certain rate onto another spool, with a traversing mechanism between the two spools to

create the desired pattern or evenly wind onto an flanged spool or cylindrical core despite the

core shape. The integrity of the spool is often based on precise patterns and proper tension

control throughout the winding process. The following figure provides examples of common

spool-winding patterns:

There are various problems associated with winding and spooling applications, such as:

material tension control, setting proper dwell points, over/under-travel (which results in a

"dog bone" shape) and tapered patterns with low-friction materials or wound onto cylindrical

cores.

The following sections provide commands and example programs designed to help you handle

the challenges of spooling/winding applications.

Relative Position, Auto-Traverse Spool Winding

The following figure provides a simple representation of an auto-traversing spool winding

application.

Part 1: Programming: Spooling and Winding Overview

Loading...

Loading...