309

Common Procedures Section 7-2

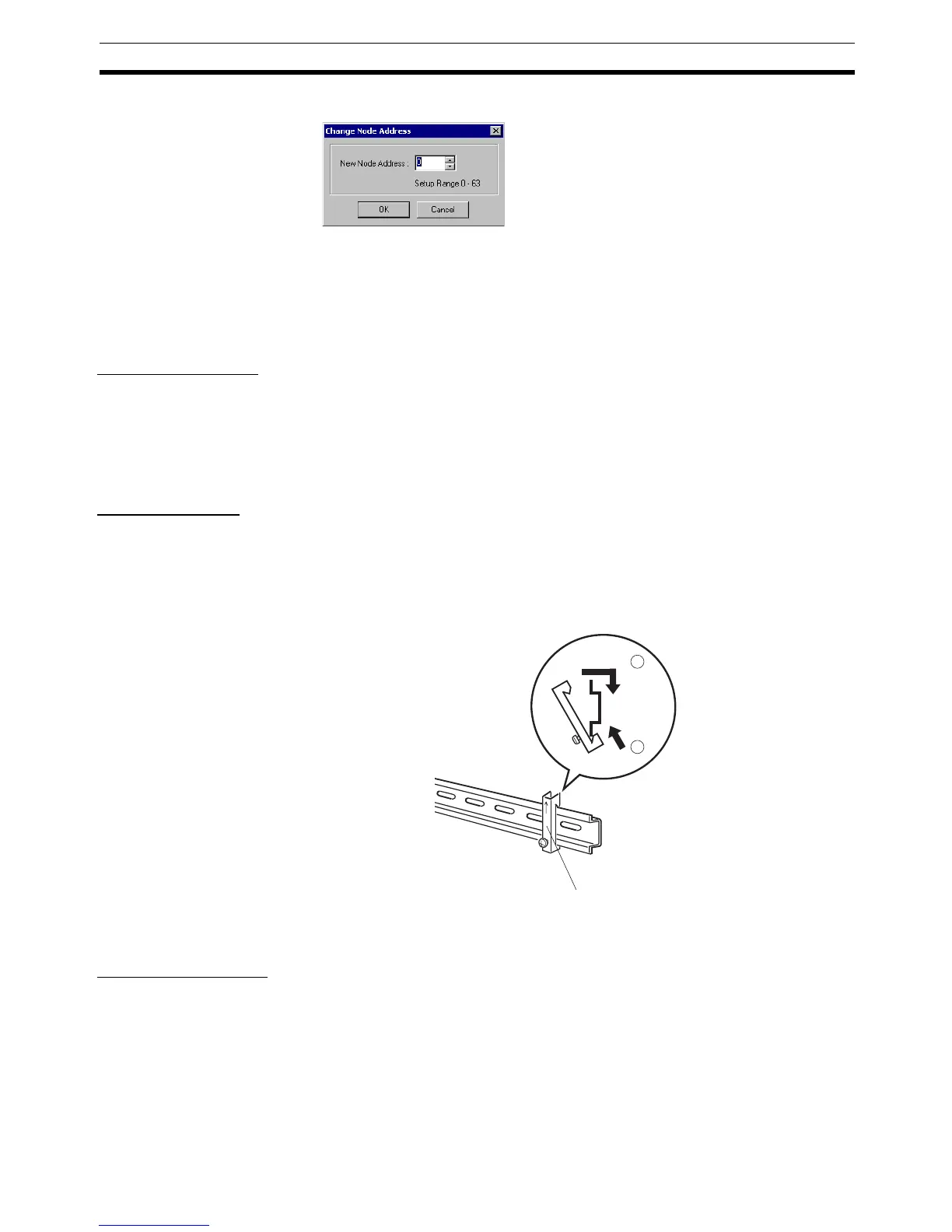

2. The following window will be displayed. Enter the node address.

3. Click the OK Button.

Note Any node address within the setting range can be used as long as it is not

already set for another node. Setting the same node address for more than

one node will cause a node address duplication error and communications will

not start.

Baud Rate Setting The baud rate of the system is determined by the baud rate set for the Master

Unit (automatic detection). Setting the baud rate for each Unit is not required.

7-2-3 Mounting in Control Panels

An Analog Slave can be mounted in a control panel using the following

method.

Using DIN Track Mount the back of the Slave to a 35-mm DIN Track. To mount the Slave, pull

down on the mounting hook on the back of the Unit with a screwdriver, latch

the DIN Track onto the back of the Slave, and then secure the Slave to the

DIN Track. Secure the Slaves by mounting End Plates on both sides of them.

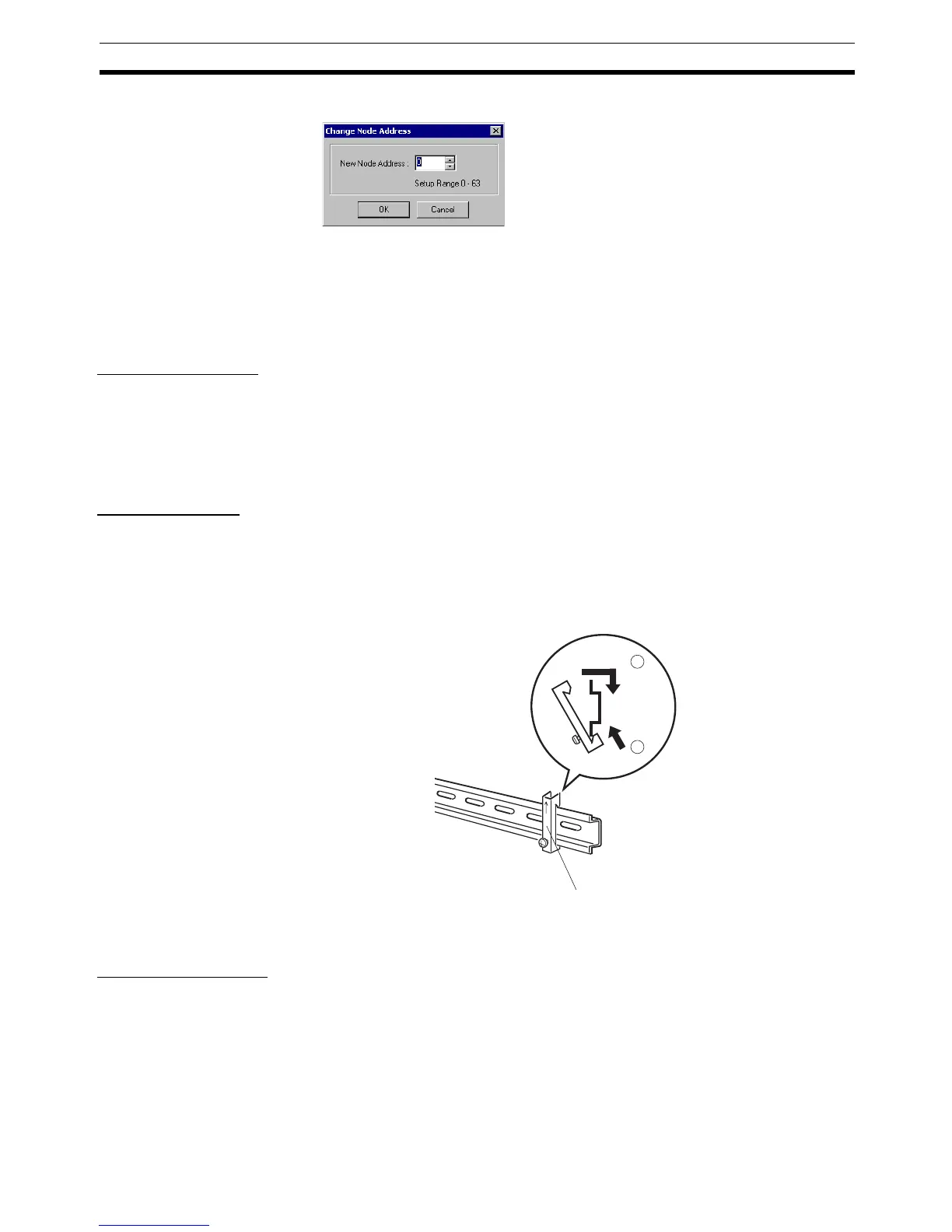

Connecting End Plates Hook the bottom of the End Plates onto the DIN Track, as shown at (1) in the

following diagram, then hook the top of the End Plates as shown at (2).

Note Always attach End Plates to both ends of Slaves connected to the DIN Track.

Mounting Direction Unless specific restrictions are given for the Slave, it can be mounted in any of

the following six directions. The input accuracy of the DRT2-TS04T depends

on the mounting method in some cases (see note).

Note The input accuracy of a DRT2-TS04T is slightly less accurate if mounted ver-

tically or facing down (mounting direction 3, 4, or 6 below) when the

DRT2-TS04T is used to replace another Temperature Input Terminal and the

existing Terminal Block is left in place. For details, refer to the Performance

1

2

End plate

Loading...

Loading...