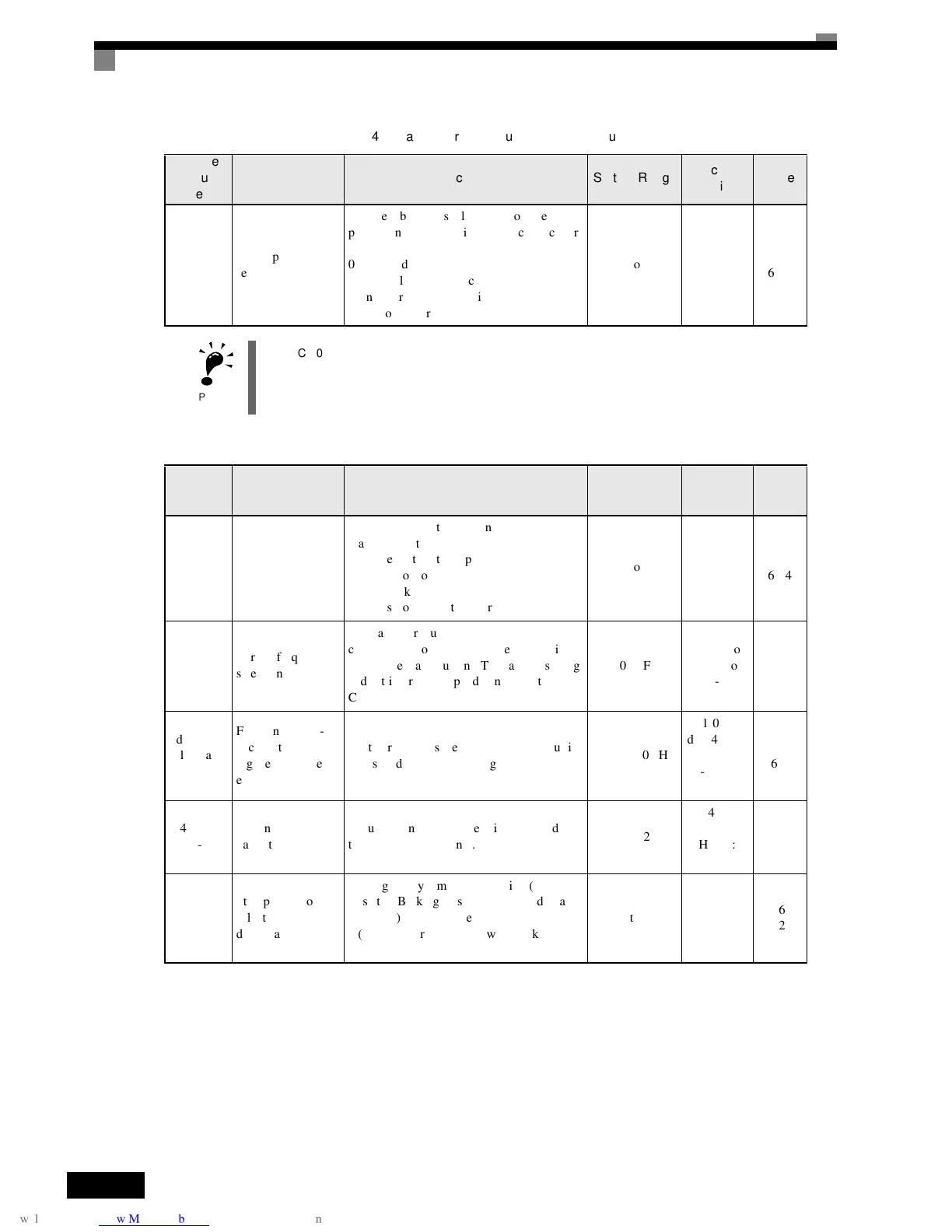

8

L1-01

Motor

protection

selection

Set

to

enable

or

disable

the

motor

overload

protection

function

using

the

electronic

ther-

mal

relay.

0:

Disabled

1:

General

motor

protection

2:

Inverter

motor

protection

3:

Vect or

motor

protection

0

to

31

5-56

6-47

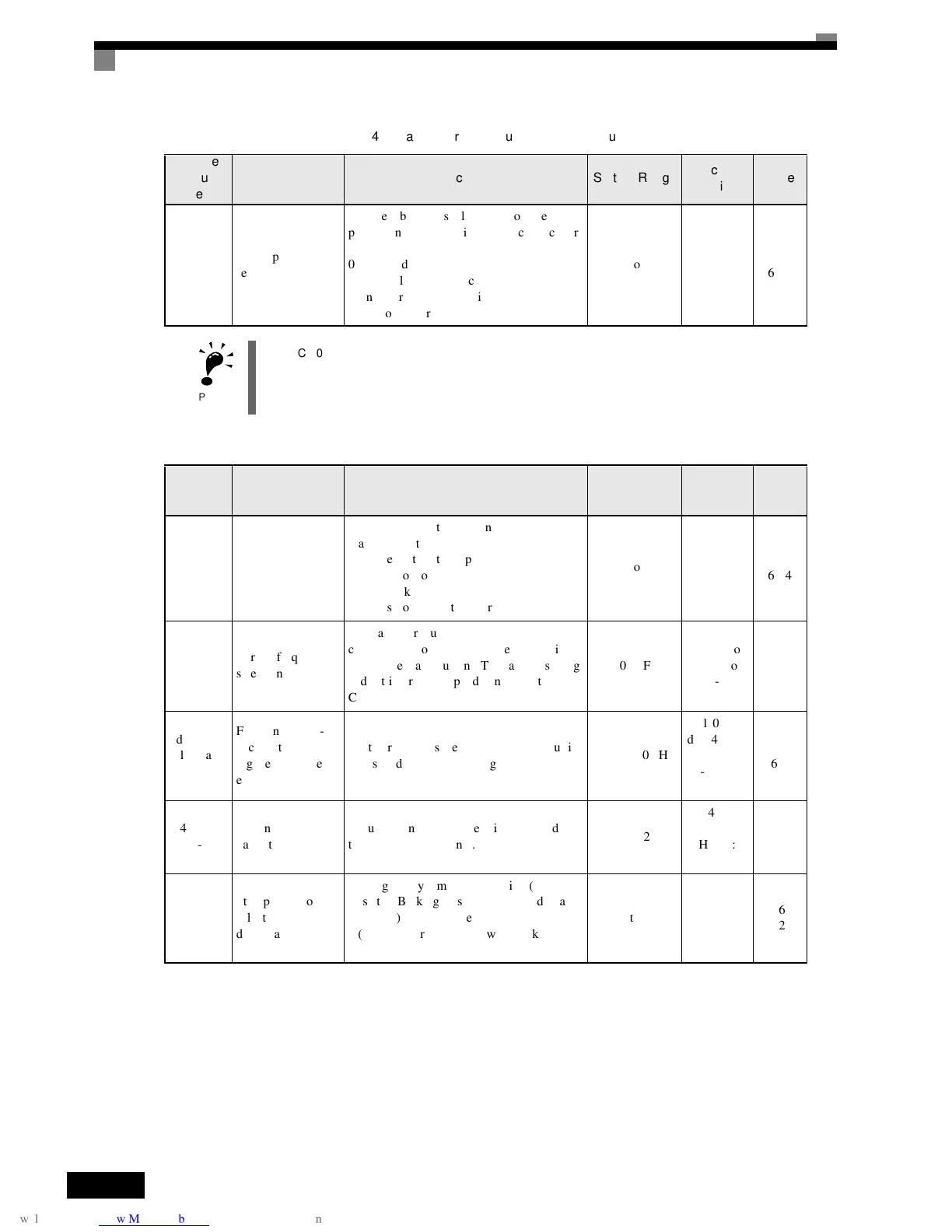

IMPORTANT

When C6-01 is set to 0 (CT), not-low noise will apply and the Inverter overload withstand ratio will be

150% of the Inverter rating per minute. When C6-01 is set to 1 (VT), low noise will apply and the Inverter

overload withstand ratio will be 120% of the Inverter rating per minute. If C6-01 is set to 1 (VT) when

overload withstand capability is required by the application, the life of the Inverter may be reduced.

Table 4.3 Parameters that are set as required

Parame-

ter Num-

ber

Name Description Setting Range

Factory

Setting

Page

b1-03

Stopping

method

selection

The

stopping

method

when

the

stop

com-

mand

is

input.

0:

Deceleration

to

stop

1:

Coast

to

stop

2:

DC

braking

stop

3:

Coast

to

stop

with

timer

0

to

30

5-13

6-14

C6-02

Carrier

frequency

selection

The

carrier

frequency

is

set

low

if

the

motor

cable

is

50

m

or

longer

or

to

reduce

radio

noise

or

leakage

current.

The

factory

setting

and

setting

range

depends

on

the

setting

of

C6-01.

0

to

F

Depends

on

setting

of

C6-01.

5-25

d1-01

to

d1-04

and

d1-17

Frequency

refer-

ences

1

to

4

and

jog

frequency

ref-

erence

Set

the

required

speed

references

for

multi-

step

speed

operation

or

jogging.

0

to

400.00 Hz

d1-01

to

d1-04:

0.00

Hz

d1-17:

6.00

Hz

5-27

6-6

H4-02

and

H4-05

FM

and

AM

termi-

nal

output

gain

Adjust

when

an

instrument

is

connected

to

the

FM

or

AM

terminal.

0.00

to

2.50

H4-02:

1.00

H4-05:

0.50

5-52

L3-04

Stall

prevention

selection

during

deceleration

If

using

the

dynamic

brake

option

(Braking

Resistor,

Braking

Resistor

Units,

and

Brak-

ing

Units),

be

sure

to

set

parameter

L3-04

to

0

(disabled)

or

3

(enabled

with

Braking

Resistor).

0

to

31

5-60

6-25

Table 4.2 Parameters that must be set (Continued)

Parame-

ter Num-

ber

Name Description Setting Range

Factory

Setting

Page

Loading...

Loading...