FP2/FP2SHMaintenance

9 − 8

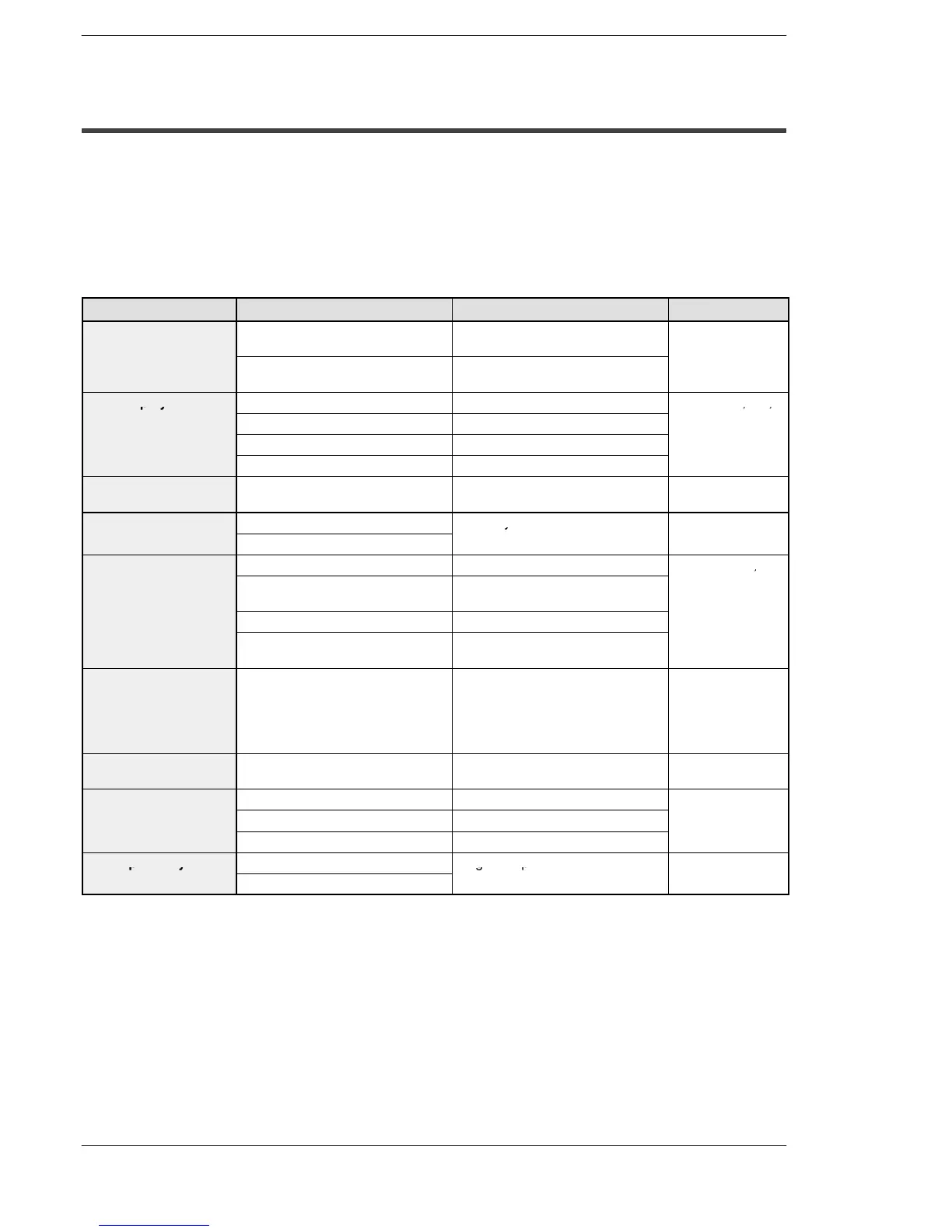

9.2 Preventive Maintenance

9.2 Preventive Maintenance

Although the FP2/FP2SH system has been designed in such a way to minimize mainte-

nance and offer troublefree operation, several maintenance aspects should be taken

into consideration.

If preventive maintenance is performed periodically, you will minimize the possibility of

system malfunctions.

Inspection item Inspection description Basis of judgement Reference

Power supply unit Check POWER LED on power

supply unit

Normal if on Section 2.7

Power supply unit Periodic replacement (20,000

hours of operation)

CPU display Check RUN LED On in RUN state Section 2.2, 2.4,

Check ERROR LED Normal if off

and 8.1

Check ALARM LED Normal if off

Check BATT. LED Normal if off

Input/output unit

display

Check input/output display LED Normal if “light” during on, and

“not light” during off

Section 2.8

Installation condition Backplane mounting looseness Securely mounted Section 4.1.1 and

Looseness and/or play in unit

4.1.2

Connection condition Looseness of terminal screw No looseness Section 4.1.3,

Proximity of connection in pinch

terminal

Pinched parallel

4.2, 4.4 and 4.5

Connector looseness Locked in

Connection condition of expan-

sion cable

Connector section is not loose

Power supply voltage

of power supply unit

Voltage between terminals FP2−PSA1: 100 to 120V AC

FP2−PSA2: 200 to 240V AC

FP2−PSA3: 100 to 240V AC

FP2−PSD2: 24V DC

Section 4.2.1

Power supply voltage

for input/output

Voltage between terminals Within the specified range of each

unit

Section 2.9

to 2.11

Ambient environment Ambient temperature 0to55°C/32 to 131°F Section 4.1.1

Ambient humidity 30 to 85% RH

Operating condition No dust or corrosive gas

Backup battery Battery for CPU Regular replacement Section 9.1.1

Battery for IC memory card

Loading...

Loading...