5: Performance Verification Verification Test Equipment

156

Internal Repairs

If the case was opened (regardless of what else the repair involved), perform all the Performance

Verification and Safety tests:

Run the Performance Verification and Safety tests (see “Test and Inspection Matrix” on page 157

and “Performance Verification Procedures” on page 160).

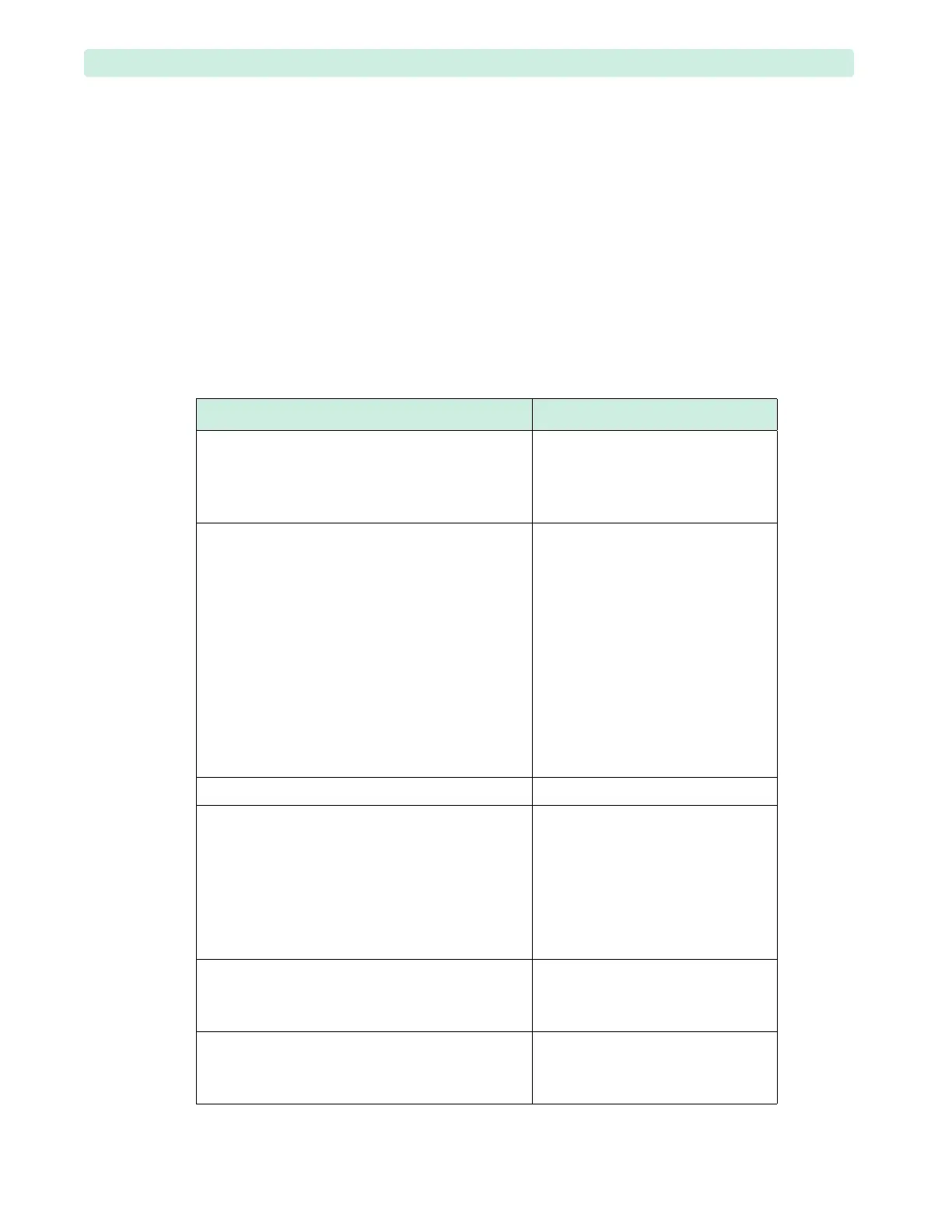

Verification Test Equipment

Tab le 3 6 lists the equipment needed to perform the Performance Verification and Safety tests, and

provides specifications for commercially available analyzers and simulators. Test equipment is called out

within each test procedure when needed.

Table 36 Verification Test Equipment

Equipment Specification

ECG Simulator (for Leads/Pads/Paddles)

Leads simulated

Amplitude accuracy

Rate accuracy

3 and 5

±2%

±2%

Defibrillator Analyzer

Waveform compatibility

Load resistance

Maximum energy

Maximum voltage

Maximum current

Energy measurement accuracy

Cardioversion measurement range

Meets all specs below using biphasic

truncated exponential waveform

50 Ω ±1% (non-inductive)

≥ 200 J

≥ 2500 V

≥ 50 A

< 20 J: ≤ ±0.4 J;

≥ 20 J: ≤ ±2% of reading

–120 to +380 ms

Test Load

50 Ω ±1% (non-inductive)

Pacer test

Load impedance

Current measurement accuracy

Rate measurement accuracy

Waveform duration measurement accuracy

≤ 400 Ω

10 mA–50 mA: ≤ ±2 mA;

50 mA–175 mA: ≤ ±4%

30–180 ppm: ≤ ±0.5%

30–180 ppm: ±1 ms

NBP test

Pressure range

Pressure measurement accuracy

> 280 mmHg

±3 mmHg

Safety test

Leakage current measurement range

Leakage current measurement accuracy

0 – 5000 μA

±2% or ±2 μA

Loading...

Loading...