Part B - System description cobas p 512

2-22 Operator's Manual - Version 1.6 - 10/2015

Measurement principle

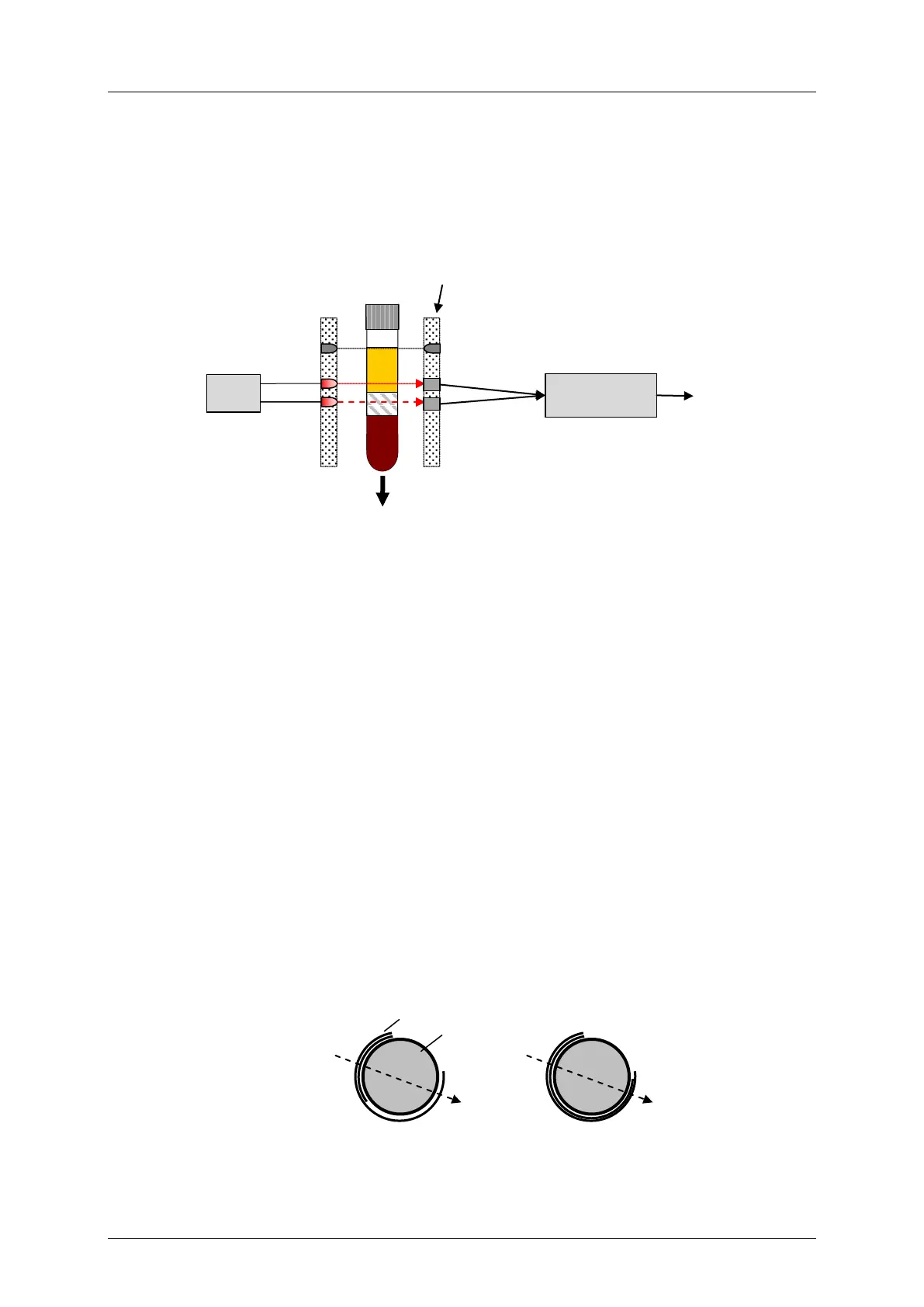

The location of liquid within the tube is performed using an optical device which is able to

detect material transitions in the tube. The system comprises two infrared lasers of different

wavelengths which pass through the tube. The transmitted signals on the other side of the

tube are sent to the Laser-LLD control unit for processing (see next figure).

Figure 2-17: Schematic diagram

Barcode label

Only plastic labels and paper labels can be used. Metallic labels or reflective labels cannot be

used.

Labels must be pasted plane to the tube (wrinkle-free, no edges sticking out, no entrapped

air) otherwise the detection of liquid level may be erroneous. Residual adhesive from

removed labels may impair the liquid level detection as well.

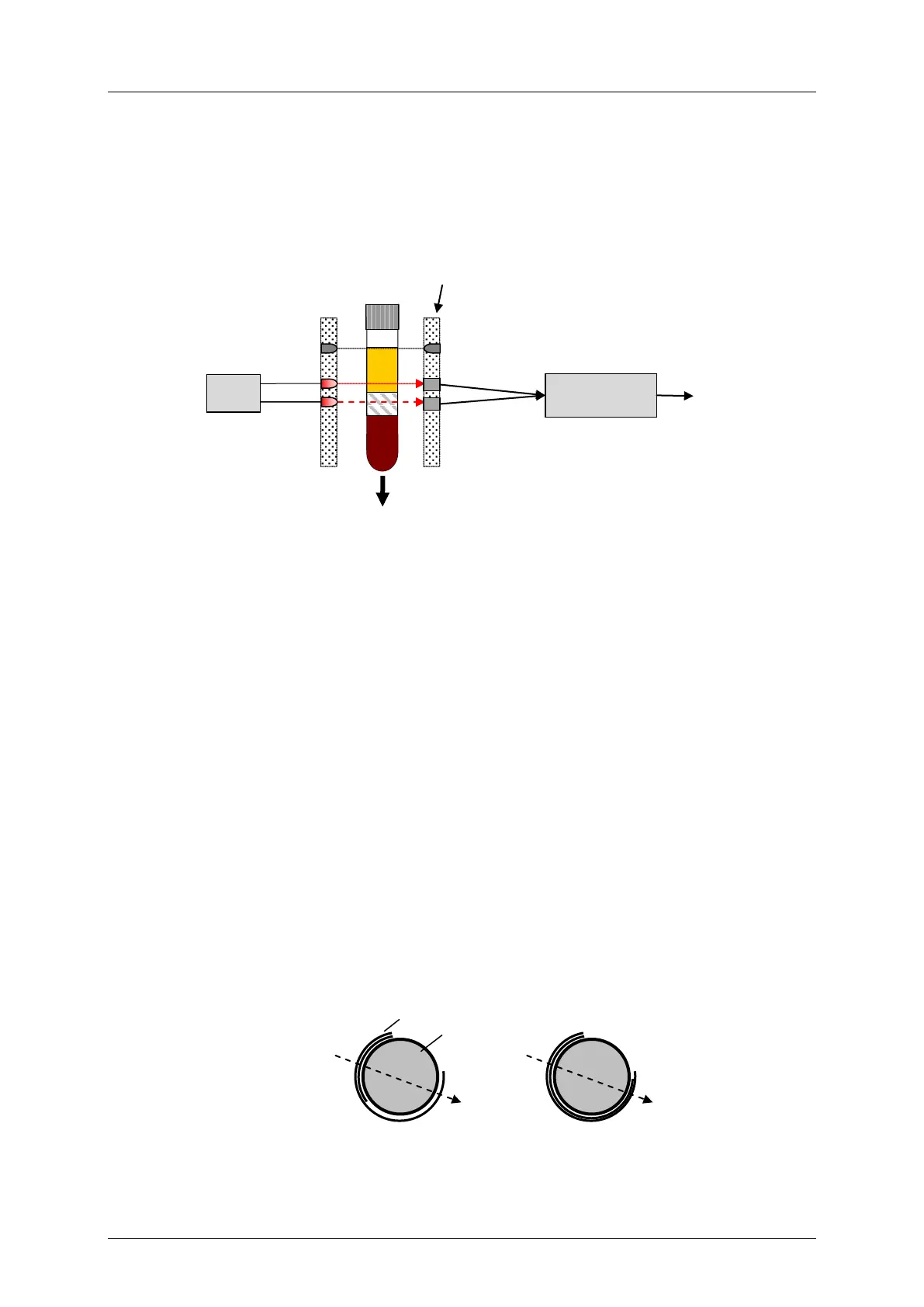

The signal of the Laser-LLD module can pass through up to 5 layers of labels (supposing a

standard label thickness of 0.07 mm) altogether. The amount of layers includes the ones to be

passed by the beams on entering the tube plus the ones on leaving the tube again (see

Figure).

Having more than 5 layers of label or using thicker labels would affect the signal and lead to

an incorrect detection of the liquid level.

Figure 2-18: Layers of barcode label

transmission

moving direction of the tube

signal passes through

3 layers of label

signal passes through

4 layers of label

to the sorting

system

Loading...

Loading...