1 -

7

GENERAL INFORMATION

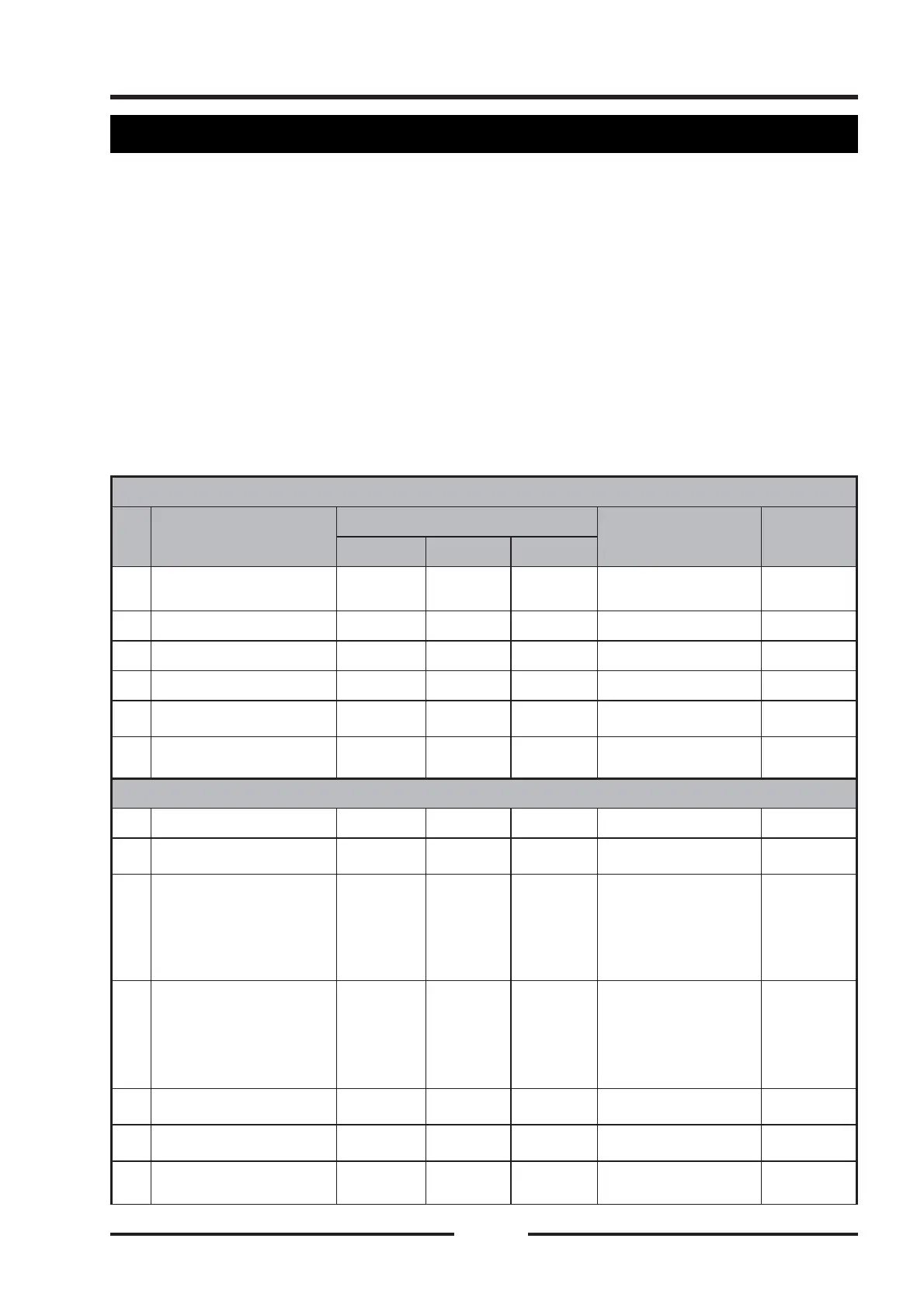

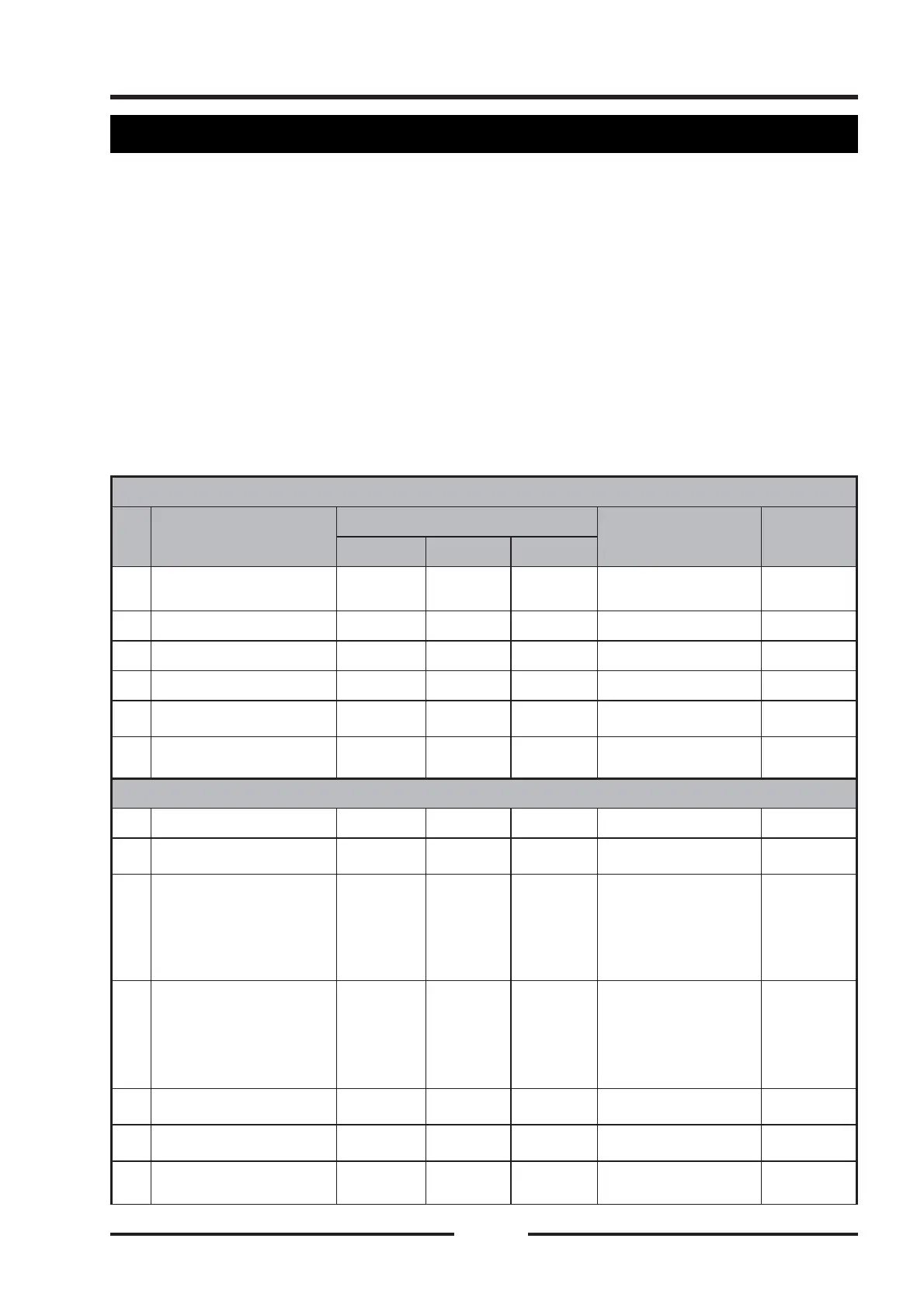

TORQUE

The following tables list the tightening torque for the major fasteners, and the parts requiring use of a

non-permanent locking agent or liquid gasket.

Letters used in the “Remarks” column mean:

L: Apply a non-permanent locking agent.

MO: Apply molybdenum disulfi de oil solution (mixture of the engine oil and molybdenum disulfi de

grease in a weight ratio 10:1).

EO: Apply engine oil.

SS: Apply silicone sealant

Lh: Left-hand Threads

R: Replacement Parts

S: Follow the specifi c tightening sequence.

Engine standard fastener torque

NO.

Fastener

Torque

Fastening part

Remarks

N·m

kgf·m

ft·lb

1

Screw M6×16

8~12

0.8~1.2

69~103.6

in·lb

2

Screw M8×25

22~28

2.2~2.8

16.2~20.7

3

Screw M6×16

16~20

1.6~2.0

11.8~14.7

4

Screw M8×25

29~35

2.9~3.5

21.4~25.8

5

Hexagon fl ange bolt

M10×1.25×25

75~85

7.5~8.5

55.3~62.7

6

Hexagon fl ange bolt

M12×1.25×30

112~128

11.2~12.8

82.6~94.4

Engine special fastener torque

1 Bolt

M12×1.25×185

112~128

11.2~12.8

82.6~94.4

CVT Clutch primary

2 Bolt

M10×1.25×80

75~85

7.5~8.5

55.3~62.7

CVT Clutch

secondary

3

Cylinder head bolt

M11×1.25×150

1. 12

2. 35

3. Tighten

at 180°

angle

1. 1.2

2. 3.5

3. Tighten

at 180°

angle

1. 8.8

2. 25.8

3. Tighten

at 180°

angle

Cylinder head

assemble bolt

Through

three

tightening

4

Box bolt combination

M10×1.25×110

1. 12

2. 28

3. Tighten

at 90°

angle

1. 1.2

2. 2.8

3. Tighten

at 90°

angle

1. 8.8

2. 20.6

3. Tighten

at 90°

angle

Lower crankcase

assembly bolt

Through

three

tightening

5

Bolt M8×90

33~36

3.4~3.7

24~27

4 lower crankcases

bolts

6

Bolt M8×40

33~36

3.4~3.7

24~27

2 upper crankcase

bolts

7

Piston nozzle pressure

regulator

18~22

1.8~2.2

13~16

Upper crankcase

cylinder bore

Loading...

Loading...