5

05.01

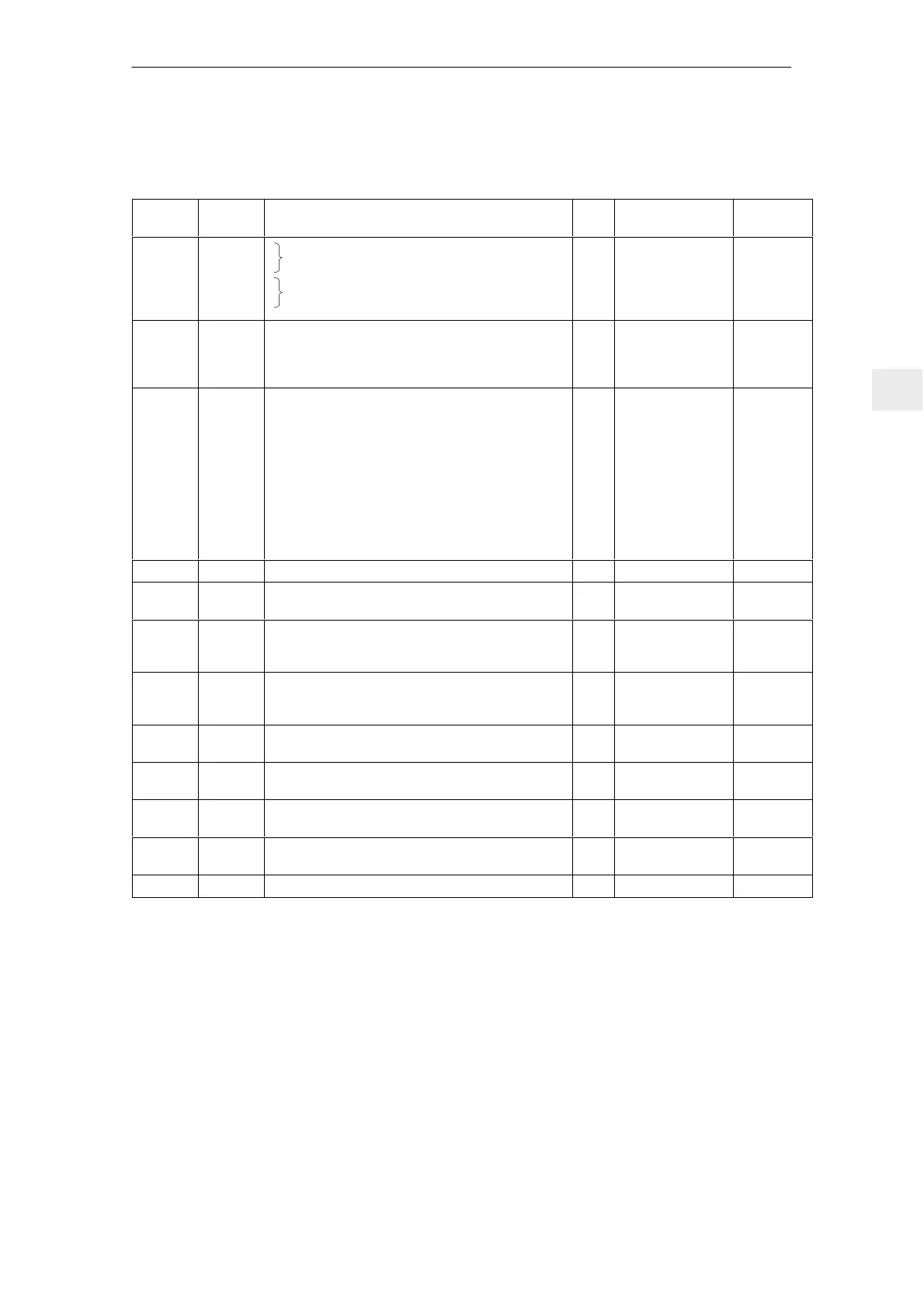

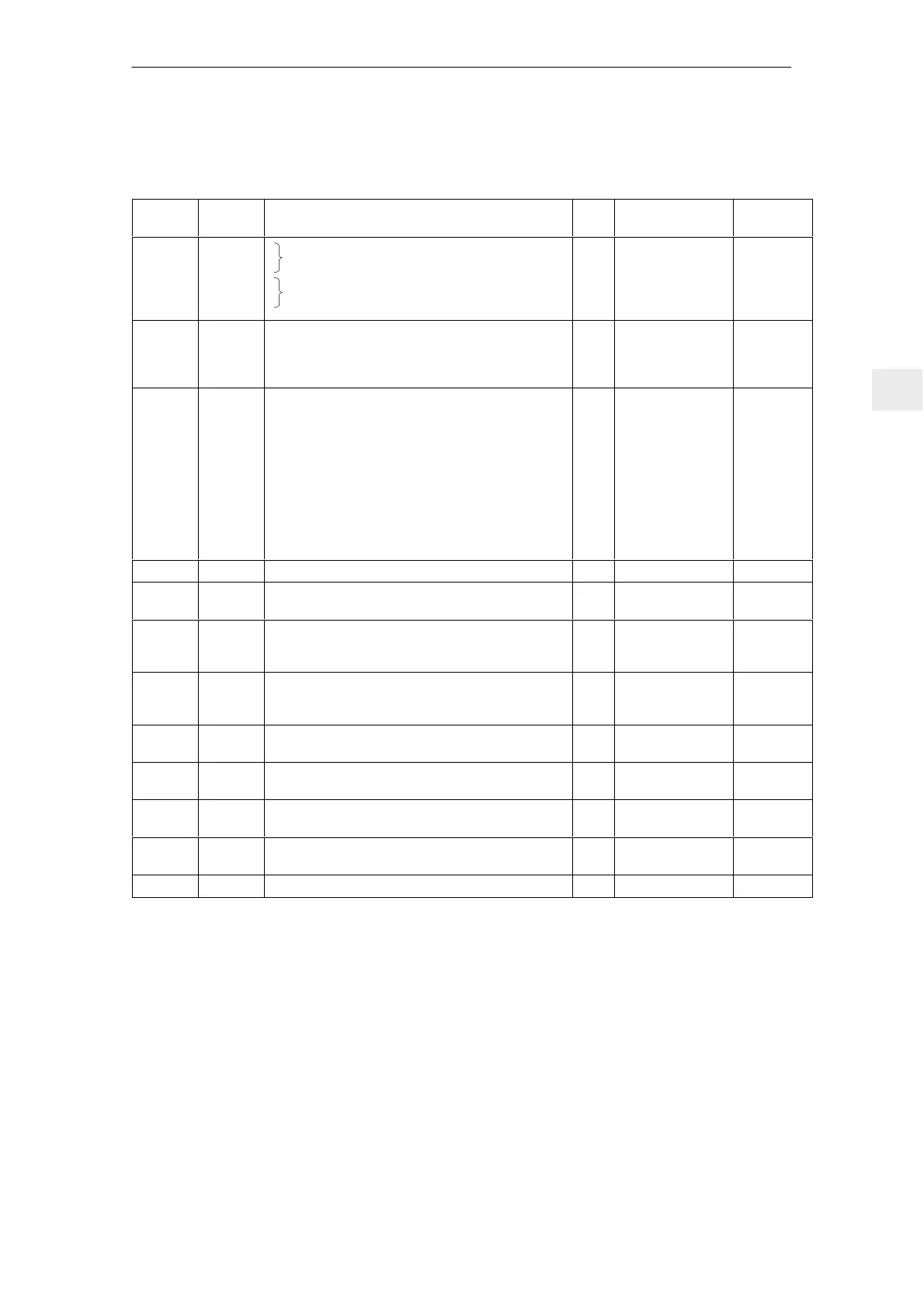

5.4 Main spindle control with analog setpoint interface 6SN1121–0BA1_–0AA_

5-117

Siemens AG 2001 All rights reserved

SIMODRIVE 611 Planning Guide (PJU) – 05.01 Edition

5.4.3 Interface overview, main spindle control

Table 5-12 Interface overview, main spindle control

Term.

No.

Desig. Function

Type

1)

Typ. voltage/

limit values

Max.

cross–sect.

56

14

24

8

X421

X421

X421

X421

Speed setpoint 1

5)

Differential input

5)

Speed setpoint 2

5)

Differential input

5)

(C axis or supplementary setpoint)

I

I

I

I

0 V ... ±10 V

max. 0.5 A

0 V ... ±10 V

max. 0.5 A

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

A91

M

A92

M

X451

X451

X451

X451

Analog input DA1 (n

act

)

Reference voltage for DA1

Analog input DA2 (utilization)

Reference voltage for DA2

I

I

I

I

–10 V ... +10 V

max. 3 mA

–10 V ... +10 V

max. 3 mA

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

9

663

65

81

X431

X431

X431

X431

Enable potential 6)

Pulse enable

Controller enable: To power–up the drives, in addition

to terminal 65, terminals 663 and 81 must also be

energized. If terminal 65 is opened, the motor brakes

with the selected deceleration time (ramp–down time).

The pulses are canceled when n

min

is fallen below.

Ramp–function generator fast stop: The motor brakes

along the torque limit after terminal 81 has been ope-

ned. When n

min

is fallen below, either the pulses are

canceled, or the motor remains magnetized.

O

I

I

I

+24 V

+21 V ... 30 V

+13 V ... 30 V

+13 V ... 30 V

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

E1 to E9 X431 Freely–programmable select terminals I +13 V ... 30 V 1.5 mm

2

AS1

AS2

X441

X441

Relay, start inhibit (checkback signal, terminal 663)

Relay, start inhibit (checkback signal, terminal 663)

NC

max.250V

AC

/1A

30 V

DC

/2 A

1.5 mm

2

1.5 mm

2

A11 to

A61

289

X441

X441

Freely–programmable relay signals

Relay contact supply

NO

I

30 V

DC

/1 A

30 V

DC

/6 A

1.5 mm

2

1.5 mm

2

672

673

674

X441

X441

X441

Axis–specific signal

Ready or no fault

NO

I

NC

30 V

DC

/1 A

30 V

DC

/1 A

30 V

DC

/1 A

1.5 mm

2

1.5 mm

2

1.5 mm

2

RS 232C X411 Serial interface for computer–supported start–up

(start–up program)

D–Sub

9–pin

X432 Spindle encoder input, BERO or

motor encoder output

2)3)

D–Sub

15–pin

X433 BERO connection

2)3)4)

D–Sub, 9

pin.

X412 Motor encoder D–Sub, 15

pin

X151 Equipment bus

1) I=input; O=output; NC=NC contact; NO=NO contact (for signal: Closed=high, open=low)

2) The BERO can either be connected to X433 or to X432.

3) X433 is only available for Order No.: 6SN1121–0BA11–0AA1.

4) BERO type: 3–conductor PNP NO contact, e.g. BERO M30 Order No.: 3RG4014–0AG01 or

BERO M12 Order No.: 3RG4012–3AG01

The BERO cable must be shielded.

5) The cable shields of setpoint cables must be connected at both ends.

6) The terminal may only be used to enable the associated drive group.

5 Control Modules

Loading...

Loading...